GWSP75 scroll vacuum pump use in degassing vacuum machine, oil less pump

- Category: >>>

- Supplier: Shenyang Geowell Applied Technology Co. Ltd.

Share on (1600726149780):

Product Overview

Description

Product Descriptions

GWSP Oil free Scroll Vacuum Pump

GWSP series oil free scroll vacuum pump, also refer to as vortex pump, dry scroll pump, oil free scroll pump, oilless scroll pump, dry scroll vacuum pump, oil free vortex vacuum pump is perfectly used in semiconductor industry, photoelectric, materials, medical, energy, aerospace, analyzing instruments and vacuum systems, with the advantages of compact structure, small size, light weight and low vibration, low noise, low energy consumption, suitable for global power supply, one button start, can be frequently started and stop between atmospheric pressure and vacuum.

GEOWELL is a professional manufacturer of scroll vacuum pumps with over 20 years of field experience, the longest performance hours and the largest sales in China, GEOWELL's GWSP series scroll vacuum pumps are the premium choice for clean pumping technology.

Technical Specifications

| Model | GWSP75 | ||

| Displacement | 50Hz | cfm | 2.2 |

| m3/h | 3.6 | ||

| l/s | 1.0 | ||

| l/min | 60.0 | ||

| 60Hz | cfm | 2.5 | |

| m3/h | 4.3 | ||

| l/s | 1.2 | ||

| l/min | 72.0 | ||

| Ultimate Pressure | Torr | ≤6.0*10-2 | |

| psi | ≤1.2*10-3 | ||

| mbar | ≤8.0*10-2 | ||

| Pa | ≤8 | ||

| Noise Level | dB(A) | ≤57 | |

| Leakage | mbar·l/s | 1*10-7 | |

| Max. Inlet/Exhaust Pressure | MPa | 0.1 / 0.13 | |

| Ambient Operation Temp. | ℉ | 41~104 | |

| Cooling Type | Air cooled | ||

| Inlet/Exhaust Flange | KF25/KF16 | ||

| Motor 1 phase | Power | kW | 0.55 |

| Voltage | V | 110~115 (60Hz), 200~230 (50Hz) | |

| Speed | rpm | 1425 (50Hz),1725 (60Hz) | |

| Plug | North America, Europe, UK/Ireland, India | ||

| Motor 3 phase | Power | kW | 0.55 |

| Voltage | V | 200~230 or 380~415 (50Hz), 200~230 or 460 (60Hz) | |

| Speed | rpm | 1425 (50Hz),1725 (60Hz) | |

| Dimensions | 1 phase | mm | 455*260*275 |

| 3 phase | mm | 455*260*275 | |

| Net Weight | 1 phase | kg | 21 |

| 3 phase | kg | 20 | |

| Others | With air flush | ||

Safety Precautions

The GWSP series oil free scroll vacuum pumps are suitable for clean processes only.

Do not pump toxic, explosive, flammable or corrosive substances or substances which contain chemicals, solvents or particles.GEOWELL will not perform maintenance work on pumps which have used special gases or other hazardous substances. Be sure the inlet gas temperature must be lower than 122℉.

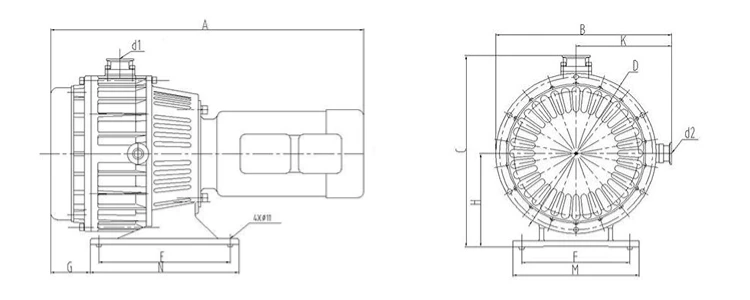

Construction in Details

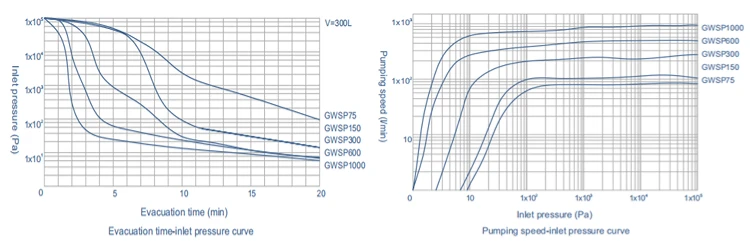

Performance curves

Features and Benefits

Oil free clean vacuum

No oil back-diffusion, no oil mist exhaust,

provide clean vacuum environment

Wide product lineup

Pumping speed covers 1.8~35.4cfm, limited vacuum level 7.5*10-3~6.0*10-2Torr

Suitable for all type of power supply around the world

110/220/380/460V, 50/60Hz for choose

Low vibration, low noise

57~63 dB(A), smooth operation

High efficiency, ease of maintenance

No water cooled, no oil lubricated, daily maintenance free

Applications

Semiconductor industry

Vacuum sputtering machine.

IC plasma cleaning machine.

IC plasma polishing machine.

IC packaging machine.

IC transmission chamber.

Photoelectric industry

LED vacuum annealing furnace.

Load lock/transfer chambers.

Glove box.

LED packaging machine.

Liquid crystal injection and packaging.

Material industry

Vacuum annealing furnace.

Vacuum diffusion oven.

3D metal printing.

Single crystal growth furnace.

Microwave drying machine.

E-beam/Laser melting.

Vacuum degassing.

Vacuum gas substitution.

Food and drug industry

Freezing dryer.

Vacuum storage.

Medical equipment

Low temperature plasma sterilizer.

Vacuum storage.

Dental equipment.

Energy industry

SF6 Gas recovery machine.

Lithium battery drying and packaging machine.

Analyzing instrument and device

Spectroscopy/scanning electron microscopy

Space environment simulation machine

Helium Leak detector

Mass spectrometer

Cryopump regeneration

Accelerators/synchrotrons

Vacuum equipment

Oil free ultrahigh vacuum unit

Oil free vacuum unit

Certificates

GEOWELL created a road of independent R&D of oil-free scroll vacuum pump technologies. From basic theoretical research, application development to mass production, GEOWELL accumulated more than 60 technical patents and proprietary technologies, and certificated with CE of Europe, EAC of RUSSIA and ISO9001.

The Quality Control

GEOWELL has integrated quality concept into every aspect of product manufacturing. Quality control starts from raw materials incoming, built up and implement standards operating procedures from incoming raw materials, manufacturing, assembly, to shipment, all conduct quality inspection. strictly implements testing standards, and makes data as only criterion for quality inspection.

Packaging & Shipping

Company Information

GEOWELL VACUUM CO.,LTD. is a HI-TECH enterprise in China dedicating in manufacturing, research and development, marketing of oil free scroll vacuum pumps and vacuum compressors since 2002. GEOWELL has been providing users and partners with premium quality products that are efficient and dependable, GEOWELL believe the integration of high performance and high reliability product and service will bring the highest value to both our customers and ourselves.

Exhibitions

Question & Answers

Q: How long can I get the feedback after we sent the inquiry?

A: We will reply you within 12 hours in working day.

Q: Are you direct manufacturer?

A: Yes, we are direct manufacturer with factory and international department; we manufacture and sell all our products by ourselves.

Q: When can you delivery the product to us?

A: Since we are a factory with large warehouse, we have abundant products in store, so we can delivery within 7 days after get your deposit.

Q: Can I add logo to the products?

A: Of course, but we usually have quantity requirement. You can contact with us for details.

Q: How to guarantee the quality and after sales service of your products?

A: We conduct strict detection during production from raw material come in to product delivering shipment. Every product must go through 4 steps inspection from casting, machining, assembling, and performance testing within our factory before shipment, also intact packaging test are insured.

Q: What is your warranty term?

A: There is a 12 months warranty for our export products from the date of shipment. If warranty has run out, our customer should pay for the replacement part.

Q: Is the sample available?

A: Yes, usually we send our samples by Fedex, DHL, TNT, UPS, EMS, SF, Depon, it will take around 3 to 4 days for our customer receive them, but customer will charge all cost related to the samples, such as sample cost and air freight. We will refund our customer the sample cost after receiving the order.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices