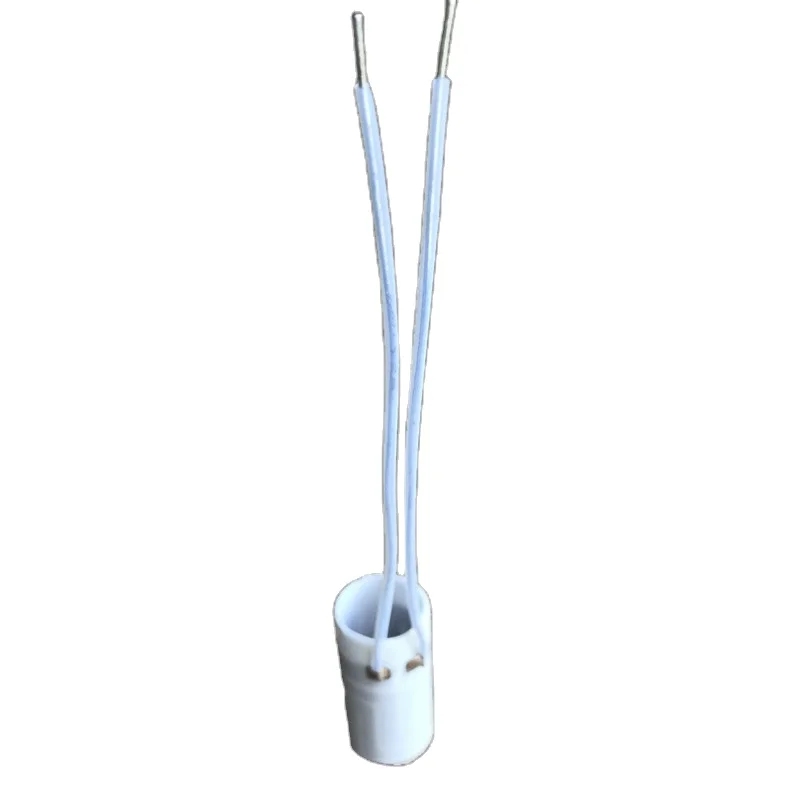

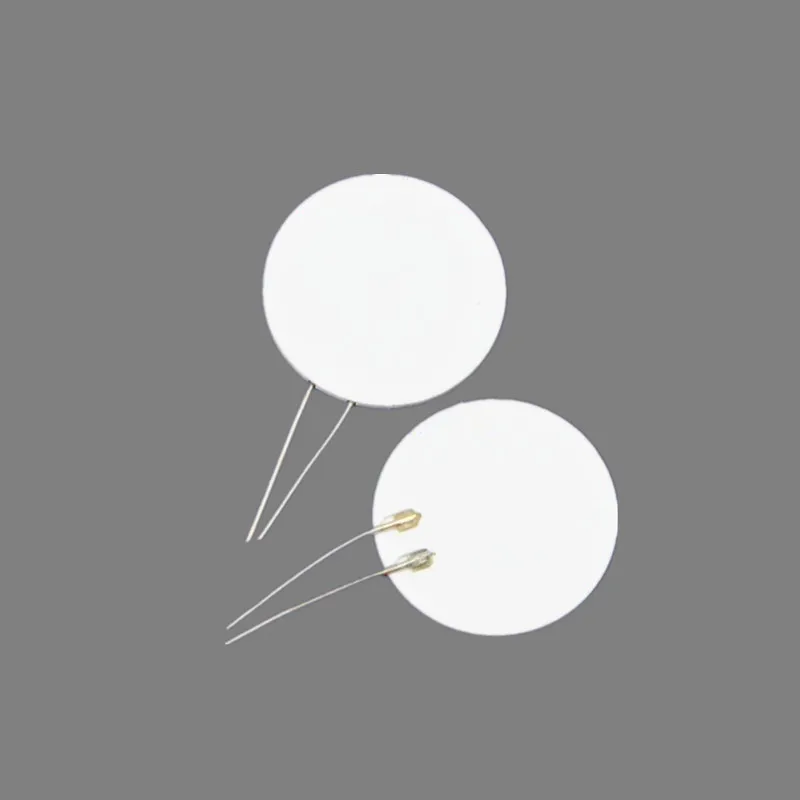

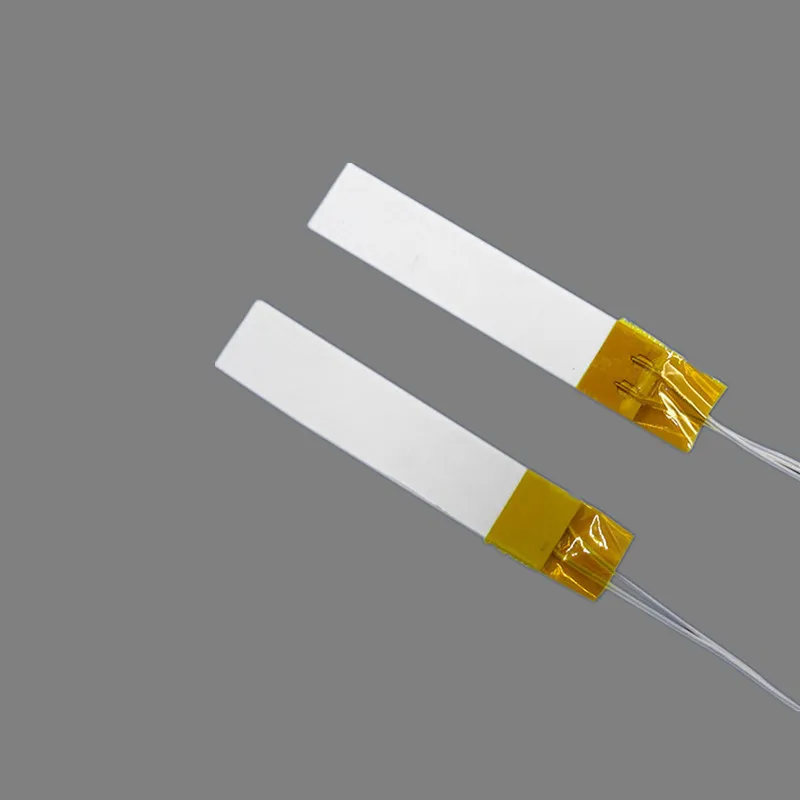

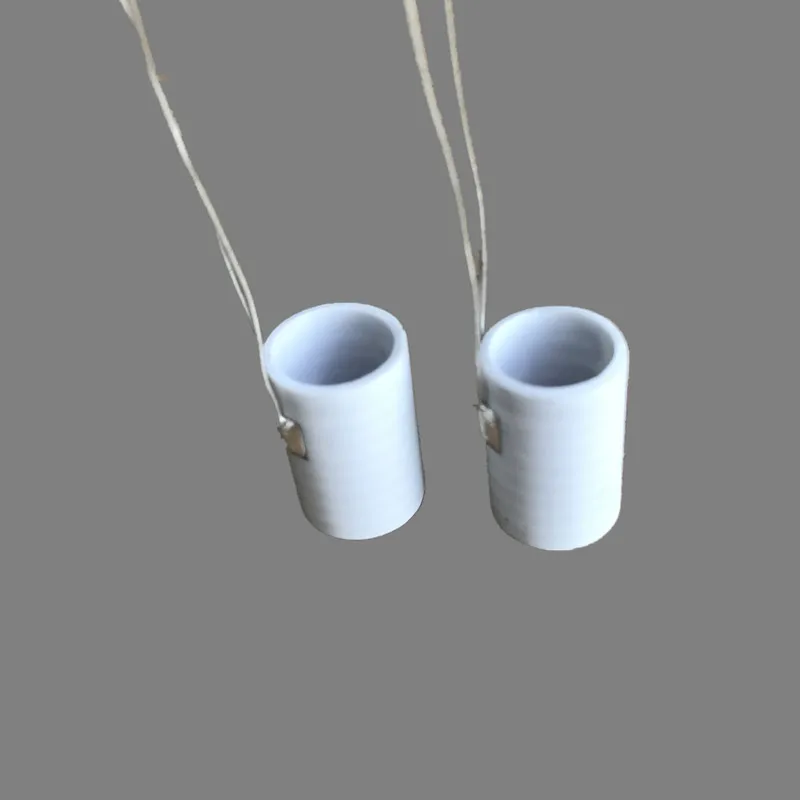

OEM MCH Ceramic Heating Ring / Al2O3 Alumina Electronic Ceramic Heater Parts

- Category: >>>

- Supplier: Hunan Global New Material Technology Co. Ltd.

Share on (1600726815437):

Product Overview

Description

Products Description

OEM MCH Ceramic Heating Ring / Al2O3 Alumina Electronic Ceramic Heater Parts

Alumina ceramic has the characteristics of excellent insulation, heat resistance, low coefficient of thermal expansion, high

mechanical strength, good thermal conductivity and chemical corrosion resistance. It is nonflammable, rust-free, strong and not easy to get damaged. Alumina ceramic has high hardness. Its Rockwell hardness is only inferior to diamond, far exceeding steel and stainless steel. Under the same working conditions, it can prolong the service life of the equipment by at least ten times. Moreover, the density of alumina ceramic material is 3.5g/cm3, only half of that of steel, which can greatly reduce the equipment load.

Thanks to the greats advantages of alumina ceramic, it has a wide range of applications, including iron and steel, smelting,

machinery, coal mining, chemical industry, cement, etc. Different types of products can be selected to suit different needs.

mechanical strength, good thermal conductivity and chemical corrosion resistance. It is nonflammable, rust-free, strong and not easy to get damaged. Alumina ceramic has high hardness. Its Rockwell hardness is only inferior to diamond, far exceeding steel and stainless steel. Under the same working conditions, it can prolong the service life of the equipment by at least ten times. Moreover, the density of alumina ceramic material is 3.5g/cm3, only half of that of steel, which can greatly reduce the equipment load.

Thanks to the greats advantages of alumina ceramic, it has a wide range of applications, including iron and steel, smelting,

machinery, coal mining, chemical industry, cement, etc. Different types of products can be selected to suit different needs.

Parameters of alumina ceramic parts:

* Base plate: 95% above alumina ceramic

* Wire: Nickel wire.

* Resistance: Tungsten

* Thickness: 0.7 ~ 2.0mm/Customized

* Voltage: 3.7V, 4.5V, 5V, 7V, 6V, 9V, 12V, 24V, 36V, 110V, 220V, 380V, etc

* Resistance: 0.3 ~ 1500 ohm

* Wire: Nickel wire.

* Resistance: Tungsten

* Thickness: 0.7 ~ 2.0mm/Customized

* Voltage: 3.7V, 4.5V, 5V, 7V, 6V, 9V, 12V, 24V, 36V, 110V, 220V, 380V, etc

* Resistance: 0.3 ~ 1500 ohm

Features of alumina ceramic parts:

* Customized structure, shape, size, resistance and power;

* Good thermal uniformity and high power density;

* Resistance-temperature change is linear, and temperature can be easily controlled by controlling resistance or voltage;

* Rapid temperature rise and temperature compensation;

* High thermal efficiency, even heating and energy saving (unit heat consumption is 20-30% less than PTC);

* Electric insulating and safe on the surface.

* Anti-acid, alkali and other corrosive substances;

* Environment-friendly: free of harmful substances such as lead, cadmium, mercury, etc.

* Good thermal uniformity and high power density;

* Resistance-temperature change is linear, and temperature can be easily controlled by controlling resistance or voltage;

* Rapid temperature rise and temperature compensation;

* High thermal efficiency, even heating and energy saving (unit heat consumption is 20-30% less than PTC);

* Electric insulating and safe on the surface.

* Anti-acid, alkali and other corrosive substances;

* Environment-friendly: free of harmful substances such as lead, cadmium, mercury, etc.

Application of alumina ceramic parts:

* Heat preservation and heating

* Medical Treatment

* Electric water cup ultrasonic

* Coffee machine

* Home electric appliances

* Medical Treatment

* Electric water cup ultrasonic

* Coffee machine

* Home electric appliances

Details Images

Product Paramenters

Parameters of Alumina Ceramic | ||||||||||||

Item | Test Condition | 95% AL2O3 | 99% AL2O3 | 99.7% AL2O3 | ||||||||

Physical properties | Density | g/cm3 | >3.6 | 3.89 | 3.96 | |||||||

Moisture absorption | % | 0 | 0 | 0 | ||||||||

Mechanical properties | ROHS Hardness | ≥85 | ≥89 | ≥89 | ||||||||

Flexural strength | psiX103 | 20℃ | 358 | 550 | 550 | |||||||

Compressive strength | psiX103 | 20℃ | 2068(300) | 2600(377) | 2600(377) | |||||||

Fracture toughness | Mpa.m3/2 | K(l c) | 4.3 | 5.6 | 6.0 | |||||||

Maximum use temperature | ℃ | 1450 | 1600 | 1650 | ||||||||

Thermal expansion coefficient | 1X10-6/℃ | (25-1000℃) | 7.6 | 7.9 | 8.2 | |||||||

Thermal shock resistance | ℃ | Tc | 250 | 200 | 200 | |||||||

Thermal conductivity | w/mok | 20℃ | 16 | 30 | 30.4 | |||||||

Volume resistivity | Ohm/cm2 | 100℃ | >1013 | >1014 | >1014 | |||||||

Dielectric breakdown strength | KV/mm | 8.7(220) | 8.7(220) | 8.7(220) | ||||||||

Dielectric constant | (E) | 1MHz25℃ | 9 | 9.7 | 9.7 | |||||||

Dielectric constant (100MHz) | (E) | 9.5 | ||||||||||

Company Profile

Located in Hunan province, Global New Material Technology Co.,Ltd is specialized in the manufacturing of advanced ceramic components based on customer specification. We cover an area of 6000 square meters and are staffed with about 100 workers. The main products include high purity alumina (Al2O3) ceramic and zirconia (ZrO2) ceramic parts, such as ceramic tubes, sheets, substrates, bars, discs, screws, bolts, etc. We focus on providing cost effective solutions to wear and corrosion problems in a wide range of applications and industries such as textile, machinery, electric appliances, communications, etc. We make OEM customized production based on specification.

With strict quality control and our best service, the products have been sold well on the domestic market and exported to many countries in North America, Europe, Middle East, South East Asia, etc.

Our mission is “Quality, Value and Innovation”. We look forward to a long-term business relationship with you.

With strict quality control and our best service, the products have been sold well on the domestic market and exported to many countries in North America, Europe, Middle East, South East Asia, etc.

Our mission is “Quality, Value and Innovation”. We look forward to a long-term business relationship with you.

Production equipment

Recommend Products

Certifications

FAQ

Why us?

* Professional manufacturer since 2010.

* Strict quality control on production process and tolerance.

* Customized production based on your specification.

* On-time delivery and reliable support and service.

* Inventory available for quick shipment.

* We keep confidentiality of all the drawings and business information between us.

* Strict quality control on production process and tolerance.

* Customized production based on your specification.

* On-time delivery and reliable support and service.

* Inventory available for quick shipment.

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a trading company and a manufaturer.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t have a drawing, just tell us your idea, we will work out the drawing for you.

What's the delivery time?

* 7-10 working days for standard products 20-30 days for customized products.

What is the MOQ?

* No limit to the quantity. We can offer the best proposal and solutions according to your condition. But we will offer more discount based on higher quantity.

What is the payment terms you accept?

* We accept T/T, LC, Western Union, Alibaba trade assurance.

OEM MCH Ceramic Heating Ring / Al2O3 Alumina Electronic Ceramic Heater Parts

OEM MCH Ceramic Heating Ring / Al2O3 Alumina Electronic Ceramic Heater Parts

OEM MCH Ceramic Heating Ring / Al2O3 Alumina Electronic Ceramic Heater Parts

OEM MCH Ceramic Heating Ring / Al2O3 Alumina Electronic Ceramic Heater Parts

We Recommend

New Arrivals

New products from manufacturers at wholesale prices