Gantry cnc metal cutting machine advertising cnc plasma cutting machines portable cnc flame 2040/1530/2030

- Category: >>>

- Supplier: Accurl Cnc Machine(anhui) Manufactory Co. Ltd.

Share on (1600733181988):

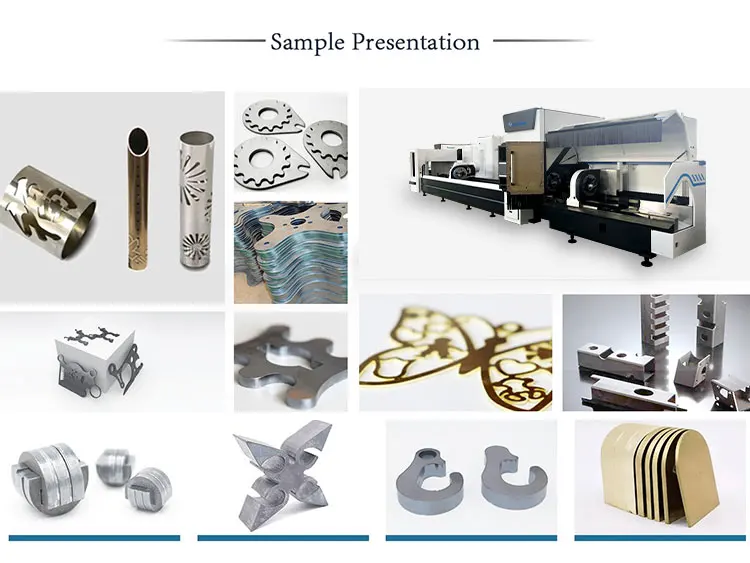

Product Overview

Description

Products Description

CNC FLAME AND PLASMA CUTTING MACHINE

ACCURL® plasma cutting machine continues to provide wide and flexible solutions with its low investment and operation cost advantages, being appropriate to production lines and automation, improved accurate cutting quality. The CPL series will be profit center of your workshop by its minimum maintenance and consumable part costs and not losing the accuracy for many long years.

Advantages+

* High cutting technology.

* Minimum operating cost

* EDGE® Connect System (Hypertherm/USA)

* Arc Glide™ THC automatic height control system

* HyDefinition® technology

* PowerPierce™ technology

* LongLife™ technology

* HyPerformance® HPR-800XD® plasma source

* TurboNest® nesting software.

* The best choice for plasma with its high productivity and accurate cutting quality.

EPS Plasma 3 Axes Series

* It offers the optimum solution to all your needswith its advanced accurate cutting quality,production line and

automation.Special plasma software and CNC controllerenables the operator to use the machine with ease.

* Thermal cutting machinesseries are used in industrial enterprises in the procurement industry. Themachine can be used as an

independent product with individual service, and aspart of the flow-mechanized lines with appropriate support.

automation.Special plasma software and CNC controllerenables the operator to use the machine with ease.

* Thermal cutting machinesseries are used in industrial enterprises in the procurement industry. Themachine can be used as an

independent product with individual service, and aspart of the flow-mechanized lines with appropriate support.

FUME EXTRACTION SYSTEM(Optional)

* Used to eliminate dust, particles and harmful fumes generated during cutting. It is fully automatic dust collecting shake

filter.

* Used for the collection of dust, particles and fumegenerated during cutting.

* Increased airflow by oval cartridge filters.

* Nanofiber Ultraweb Media to filter more efficiently than filters with standard cellulose / polyester blend media.

* Self cleaning

* DF PRO 9 ( 8000m3/h) or DF PRO 6 (8000m3/h) models can be used according to sizes of machines.

filter.

* Used for the collection of dust, particles and fumegenerated during cutting.

* Increased airflow by oval cartridge filters.

* Nanofiber Ultraweb Media to filter more efficiently than filters with standard cellulose / polyester blend media.

* Self cleaning

* DF PRO 9 ( 8000m3/h) or DF PRO 6 (8000m3/h) models can be used according to sizes of machines.

TBEVEL HEAD SYSTEM-IMA/ITALY(Optional)

Take –th 5e Axoiust Cuotft incgos Htlye ad (Optional) secondary operations such as grinding weld preparation with 5-axis Cutting

Head.

This plasma cutting bevel system is capable of cutting all bevel preparation as bevel pipe hole,sharp bottom & top Blind

bevel,cone bevel, V, X, Y and K bevel cuttings.

GRAPHITE ANTI-BURN TECHNOLOGY

The area in the entire machine tool where the laser can shoot at isall covered and protected by 20mm thick graphite anti-bruning.

To insuring the machine bed and working table not be out of shape and burned-out.

To insuring the machine bed and working table not be out of shape and burned-out.

DRIVE SYSTEM

The beam is mounted on a pair of precision REXROTH linear guide rails & with advanced German ALPHA engineering and precision

manufacturing have created the highest quality linear systems available today.

manufacturing have created the highest quality linear systems available today.

EDGE® NEW CONNECT CONTROLLER

Customized shape cutting control:

This is the next generation of Hypertherm’s industry leading automated control systems. It includes Hypertherm’s embedded cutting expertise combined with cutting machine OEM customizability. EDGE Connect offers many new software features, enhanced hardware, and field based system configuration capabilities.

SureCut:

SureCut™ allows customers to maximize performance through embedded expertise. It is brought to you via various delivery mechanisms that include Hypertherm® CAM software, CNCs, and cutting systems.

CAD/CAM NESTING SOFTWARE :

PLASMA SOURCES

XPR170 ™

The XPR170 delivers next generation X-Definition processes from very thin up to mid-range thicknesses.

MAXPRO200®

The MAXPRO200 plasma cutting system achieves impressive cut speeds, consistent cut quality and exceptional consumable life with

air or oxygen plasma gas.

air or oxygen plasma gas.

XPR300™

The most significant advance in mechanized plasma cutting technology redefines what plasma can do.

HPR400XD®

The HPR400XD delivers the ultimate in HyPerformance mild steel cutting as well as heavy-duty stainless and aluminum capability.

HPR800XD®

The HPR800XD delivers all the mild steel capability of the HPR400XD and adds the thickest stainless steel and aluminum cutting on the market today.

XPR-170® | XPR-300® | HPR400XD | HPR800XD | |

Mild steel cut capacity | ||||

Dross free | 40 | 50 | 38 | 38 |

Production pierce | 35 | 45 | 50 | 50 |

Maximum cutting capacity | 60 | 80 | 80 | 80 |

Stainless steel cut capacity | ||||

Production pierce | 22 | 38 | 45 | 75 |

Maximum cutting capacity | 38 | 75 | 80 | 100 |

Aluminum cut capacity | ||||

Production pierce | 25 | 38 | 45 | 75 |

Maximum cutting capacity | 38 | 50 | 80 | 160 |

Related Products

Company Profile

WHY CHOOSE ACCURL ?

■The right tube laser.

■Innovative features such as bevel cutting.

■Comprehensive technology and cutting data.

■Ergonomic machine concepts.

Our functional features and integrated know-how support your tubes and profiles every step of the way through the machine. Each

component is designed to achieve optimal results. Real benefits every step of the way.

■Innovative features such as bevel cutting.

■Comprehensive technology and cutting data.

■Ergonomic machine concepts.

Our functional features and integrated know-how support your tubes and profiles every step of the way through the machine. Each

component is designed to achieve optimal results. Real benefits every step of the way.

We Got 5 Stars Rating!

Exhibition

Product packaging

1.Our wooden case is after fumigation treatment. Needn't timber inspection, saving shipping time.

2.All the spare parts of themachine were covered by the some soft materials mainly using pearl wool.

3.The outmost is wooden case with fixed formwork.

4.The bottom of the wooden case has firm iron jack, convenient to handing and transport.

Our serives

The use of an interferometer records the machines X and Y axis movement during cutting to ensure accuracy.

Adjustments are made to ensure machine is precisely tuned before shipment.

Adjustments are made to ensure machine is precisely tuned before shipment.

A Marble test is performed to measure the X and Y axis, calculating any necessary adjustments to ensure perfect level and alignment along length of machine.

A collimator is run along the full length of the guide rail, testing for straightness. Adjustments are made as required to ensure linear accurae linear accuracy.

FAQ

1.Can you supply the relevant documentation?Yes, we can provide most documentation including Certificates of Analysis /Conformance; Insurance; Origin, and other export documents where required.

2.What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment.

The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

3.What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:30% deposit in advance, 70% balance against the copy of B/L.

4.What is the product warranty?

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone’s satisfaction.

5.Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.

6.How about the shipping fees?

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information.

2.What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment.

The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

3.What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:30% deposit in advance, 70% balance against the copy of B/L.

4.What is the product warranty?

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone’s satisfaction.

5.Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.

6.How about the shipping fees?

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices