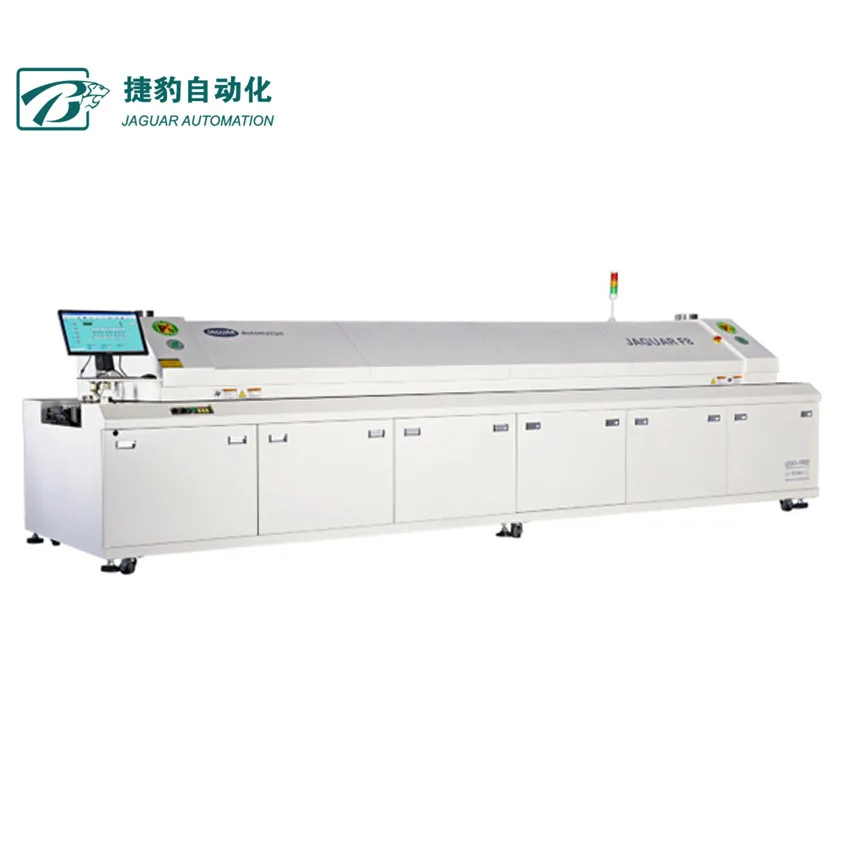

Split machine wave soldering machine

- Category: >>>

- Supplier: Shenzhen Censtar Technology Co. Ltd.

Share on (1600733748081):

Product Overview

Description

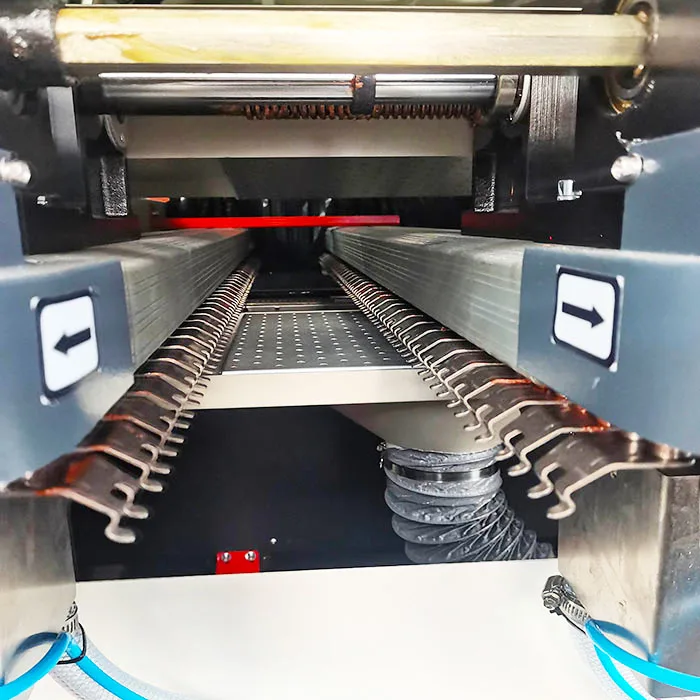

Wave soldering EFZ-450 left to right 1 red 2 hot; Heavy-duty double-hook claw transmission

I. Main features:

1. Connection device:

Linkage type entry plate connection mode, aluminum guide rail, stainless steel chain drive.

2. Transmission system:

Configuration of heavy double claw, aluminum alloy guide rail anti-deformation structure design; Manually adjust the width of the substrate; Transmission Angle can be adjusted, equipped with digital Angle display instrument; Transport speed is controlled by frequency converter and stepless speed regulation.

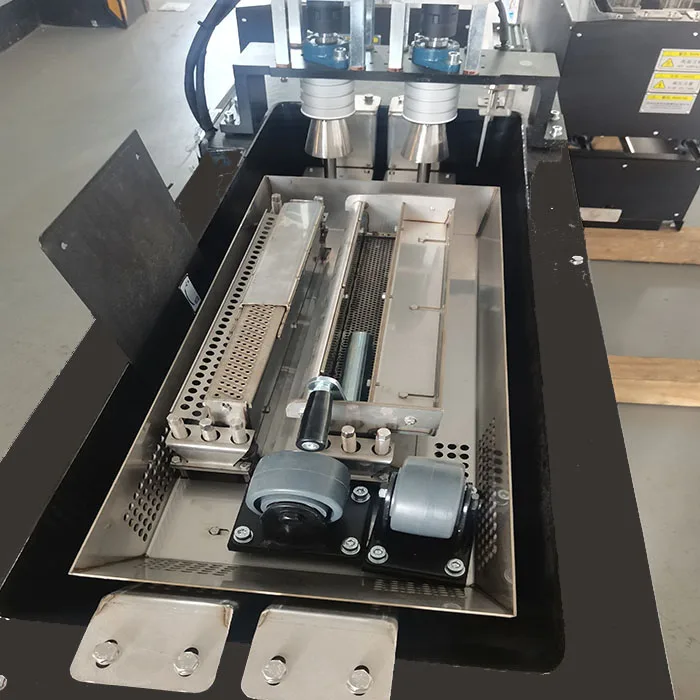

3. Tin furnace system:

The inner liner of the tin furnace is made of special cast iron material with anti-corrosion surface treatment. Direct motor drive wave peak, frequency conversion speed regulation; Tin slag diversion and oxide reduction device; Manual control of tin furnace in and out and lifting movement; External heating device,PID temperature control mode and low level alarm.

4. Spray system:

The spray movement is controlled by stepping motor. PCB spray length is automatically adjusted, spray width and speed are digitally set, spray flow rate and spray particle size are adjusted with pressure gauge fine adjustment device; Constant pressure device supply flux, flux level alarm and flux automatic addition; Powerful exhaust and filtration system; Equipped with spray and preheating isolation blade.

5. Preheating system:

New DRAWER TYPE MODULAR AND ENERGY-SAVING DESIGN, a section of infrared and two micro hot air circulation heating, thermal efficiency is higher, the temperature is more uniform. Three section temperature zone, preheating zone length of 1.8 meters,PID temperature control mode.

6. Cooling system:

Forced natural wind cooling up and down.

7. Claw washing device:

Special brush cleaning.

8. Control system:

PC+PLC electrical control system, English and Chinese Windows operating interface, data storage and other functions.

Two, technical parameters:

Substrate size | 50~450mm (W) *120mm (H) |

Feeding height | 750±20mm |

Transmission speed | 500~1800mm/Min. |

Transmission Angle | 4~7º |

Direction of transmission | left → right |

Flux tank capacity | Approx.2L |

Spray exhaust fan | 380V AC 750W |

Preheating temperature :Max.200℃

Tin furnace temperature :Max.300℃

Tin furnace capacity :Approx.550Kg

Peak height :Approx.12mm

Dimensions :5050 (L) *1520 (W) *1750 (H) mm

Machine weight :Approx.1750Kg

Power supply: Three-phase 380VAC 50Hz

Total power: Approx. 33 kw

Running power :Approx.9KW

We Recommend

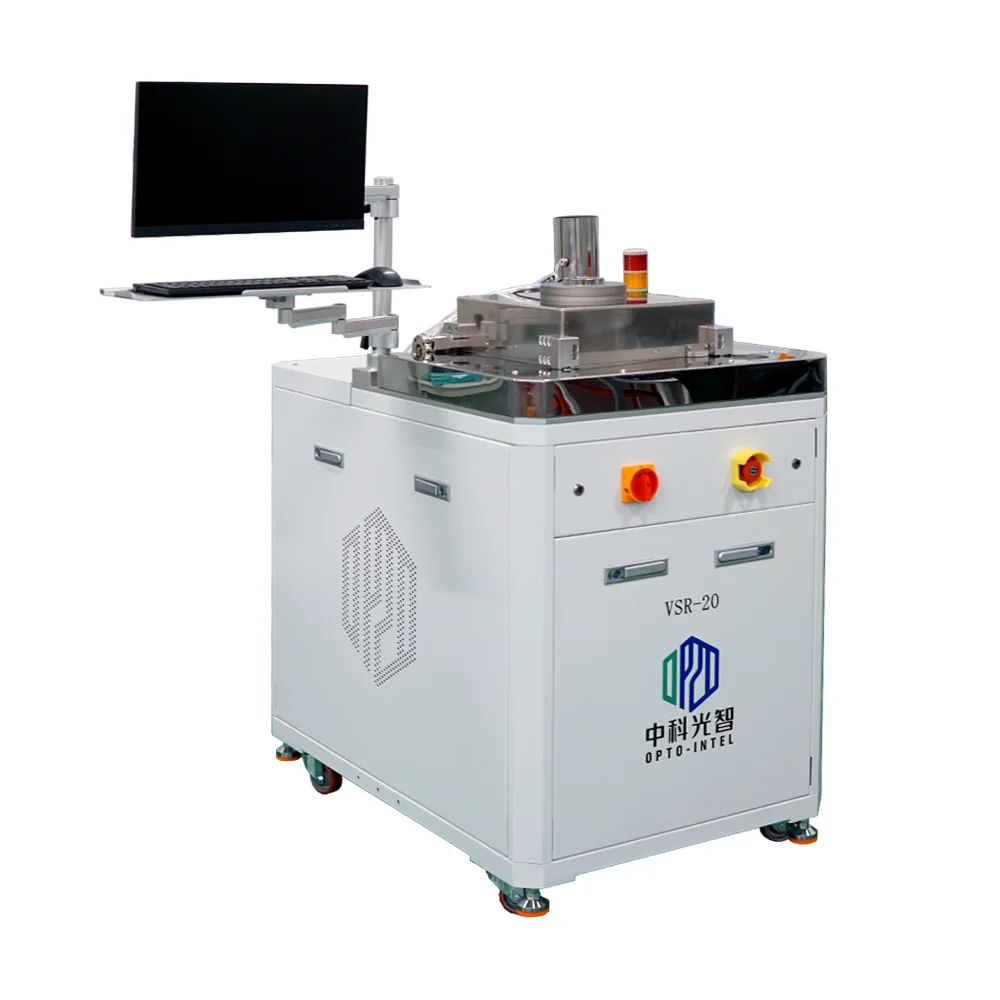

Power Module Device Vacuum Reflow Oven KD-V10N China Factory Vacuum Soldering Oven

Hanwha SM482 Plus Pick and Place Machine

Vacuum Soldering Furnace Formic Acid Vacuum Soldering System IGBT Module Packaging Oven

New Arrivals

New products from manufacturers at wholesale prices