Industry furnace S712A SMT reflow oven for welding pcb solder paste

- Category: >>>

- Supplier: Shenzhen Censtar Technology Co. Ltd.

Share on (1600733756008):

Product Overview

Description

Lead-free hot air reflow oven (SER-712A left to right)

Specification:

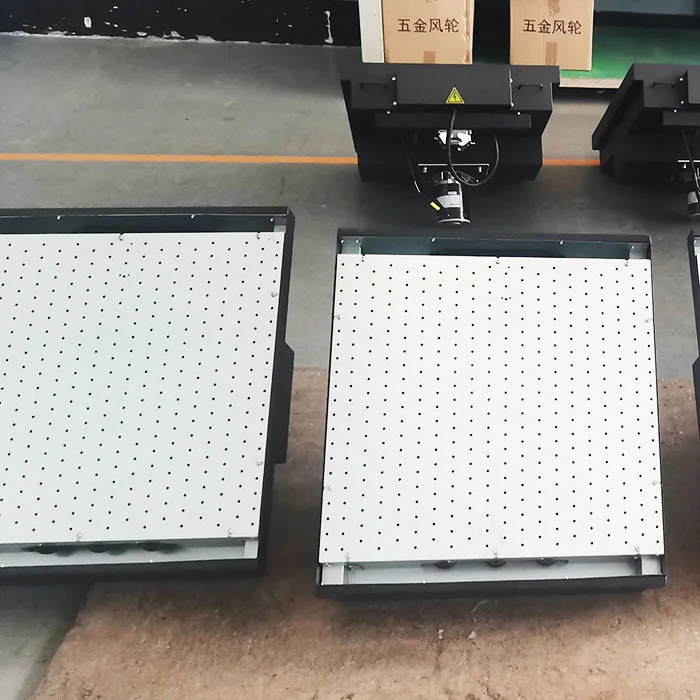

1> Heating part

—Pressurized forced hot air system, directly connected to high temperature motor drive, rear heating tube design, longer life

—Furnace hot air frequency conversion to adjust wind speed, thermal shock is controllable

—12 heating temperature zones, 24 heating modules (upper 12/lower 12)

—Automatic furnace opening mode: convenient for maintenance and cleaning inside the furnace

—Temperature control range: room temperature -320℃

—Temperature control accuracy: ±1℃ (static)

—Substrate lateral temperature deviation: ±1℃

—Temperature performance indicators comply with IPC industry standards

2>Cooling part

—Pressurized forced air cooling (dual cooling zone, drawer type rectifier board)

—Cooling zone temperature display

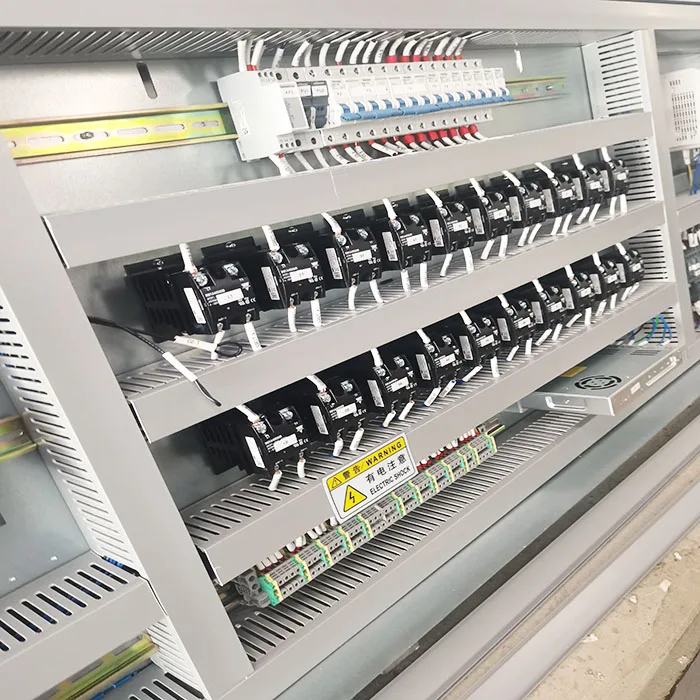

3>Control part

—PC+PLC control system, Windows operation interface, free online switching between Chinese, English, Traditional and Simplified, LCD display

—Segmented heating function

—Hot air motor abnormal alarm —Temperature curve analysis, storage, and recall function

4>Transmission part

—Synchronous transmission of anti-jamming plate chain and W440mm mesh belt

—Transmission speed: 0.3M-1.5M/Min, accuracy ±2mm/min

—Transmission height and direction: 900±20mm, left to right

—PCB width: min50mm~max400mm

—Substrate element height: Max30mm on the upper layer, Max20mm on the lower layer

—Electric/manual guide rail width adjustment

—Two-section double-sided guide rail (guide rail: special aluminum alloy material, super hard treatment to reduce wear and deformation)

5>Protection system

—Temperature out of tolerance, transmission speed out of tolerance, board drop alarm —Built-in computer and transmission UPS

—Chain automatic lubrication function (adjustable drip time)

—Computer self-diagnosis

—Operator password management, operation record

—Delayed shutdown function

6>Straight discharge device after flux filtering

—Inlet and outlet forced exhaust device

—The diameter of the inlet and outlet exhaust pipes is 145mm, and the required air volume is ≥20m³/min

7>Machine specifications

—Body size: L6490*W1372*H1450mm

—Power supply: AC35W380V50/60HZ, maximum leakage current 180ma-200ma

—Starting power: 37KW (segment start)/89KW (overall start)

Product Description

S712A Technical parameters

\t\t\t Number of heating zones \t\t\t | \t\t\t upper 12 / lower 12 \t\t\t |

\t\t\t Heating zone length \t\t\t | \t\t\t 4300mm \t\t\t |

\t\t\t Number of cooling zones \t\t\t | \t\t\t 2 \t\t\t |

\t\t\t Input voltage \t\t\t | \t\t\t 380V three-phase, 50 / 60HZ \t\t\t |

\t\t\t Dimensions(L*W*H) \t\t\t | \t\t\t 6495*1610*1515mm \t\t\t |

\t\t\t Weight \t\t\t | \t\t\t About3200 kg \t\t\t |

\t\t\t Temperature control range \t\t\t | \t\t\t 25-320 ℃ \t\t\t |

\t\t\t Power-up time \t\t\t | \t\t\t 1-5 minutes \t\t\t |

\t\t\t Profile switching time \t\t\t | \t\t\t 1-15 minutes \t\t\t |

\t\t\t Transmission way \t\t\t | \t\t\t mesh belt transmission, chain transmission \t\t\t |

\t\t\t Transmission speed \t\t\t | \t\t\t 300-1500mm / min \t\t\t |

\t\t\t High-speed rail \t\t\t | \t\t\t 900mm ± 20mm \t\t\t |

\t\t\t Net height \t\t\t | \t\t\t 900mm ± 20mm \t\t\t |

\t\t\t Allowed board width \t\t\t | \t\t\t 50-400mm (nitrogen furnace) \t\t\t |

\t\t\t Operating platform \t\t\t | \t\t\t Windows 7 \t\t\t |

Our Services

1. We’ll have a good check and a test before shipping out.

2. We provide you the friendly English User manual or the operating videos for free;

3. 24 hours technical support by email or Skype or Trade Manager or Calling.

4. 1 year machine parts free warranty;

5. Engineers available to service machinery overseas.

Packaging & Shipping

Packing method:

1)Standard box package for light and small item;

2)Strong wood package for heavy and large equipment;

Shipping way:

1)By air ,for sample and small package ,wordwide express like DHL,UPS,FedFX,EMS....

2)By sea, for large package and quantity;

3)By car or other ways as customer requested;

Company view

FAQ

1) This is the first time I use this kind of machine, is it easy to operate?

There is english manual or guide video that show you how to use machine.

If you still have any question, please contact us by e-mail / skype/ phone /trademanager online service.

2) If machine have any problem after I receive it, how can I do ?

Free parts send to you in machine warranty period.

If the part is less than 0.5KG, we pay the postage.

If it exceeds 0.5KG, you need to pay the postage.

3) MOQ ?

1 set machine, mixed order is also welcomed.

4) How can I buy this machine from you? ( Very easy and flexible !)

A. Consult us about this product on line or by e-mail.

B. Negotiate and confirm the final price , shipping , payment methods and other terms.

C. Send you the proforma invoice and confirm your order.

D. Make the payment according to the method put on proforma invoice.

E. We prepare for your order in terms of the proforma invoice after confirming your full payment.

And 100% quality check before shipping.

F.Send your order by air or by sea.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices