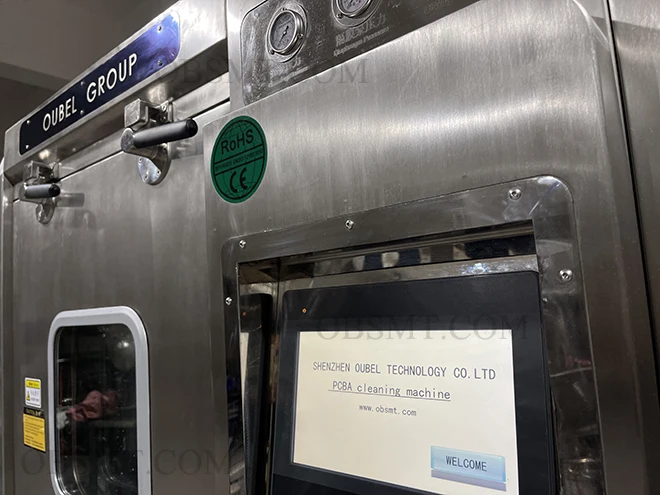

Automatic Off line PCBA Cleaning Machine PCB Washing Machine For SMT factory

- Category: >>>

- Supplier: Shenzhen Oubel Technology Co. Ltd.

Share on (1600740509071):

Product Overview

Description

Product Description

Automatic Off-line PCBA Cleaning Machine PCB Washing Machine For SMT factory

Features of PCBA Cleaning Machine:

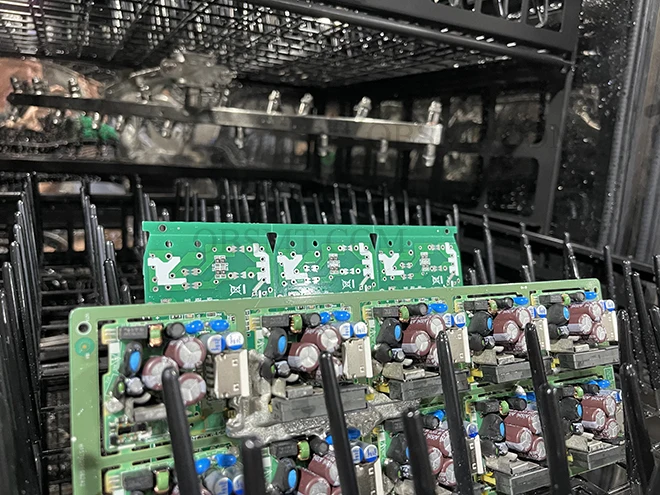

1. Comprehensive cleaning system: thoroughly and effectively clean the residual organic and inorganic substances on the product surface.

2. Full automatic cleaning mode: complete all processes of cleaning, rinsing and drying in one cleaning room, with small volume and compact structure.

3. Visualization of the whole process: the spray room is equipped with a visualization window, and two LED lights are installed to make the cleaning process clear at a glance.

4. Super large cleaning capacity: 650mm (L) * 600mm (W) * 160mm (H) three-layer design, to meet the larger product size and higher cleaning capacity;

5. Scientific nozzle design: adopt left and right increasing distribution to improve cleaning efficiency; Up and down dislocation distribution, completely solve the cleaning blind area.

6. Nozzle pressure adjustable design: reduce the hidden danger of collision and splash caused by high pressure spray in the cleaning process of small size products.

7. Standard dilution tank heating system: greatly improve the cleaning efficiency and shorten the cleaning time.

8. Large size touch screen operation interface: stable and reliable color touch screen, which can set different cleaning process parameters according to different products, making the operation easier.

9. High standard cleanliness: the degree of ion pollution fully meets the class IIIstandard of ipc-610d (lower than 1.56) μ G / cm2, standard) and class I standard of MIL28809.

10. Convenient matching method of cleaning agent: it can be added manually, or DI water and chemical solution can be automatically matched according to the set proportion (5% - 25%).

Specification of PCBA Cleaning Machine:

Model | OB-C800 |

Dimensions | 1300mm(L) × 1400mm(W) × 1950mm(H) |

Cleaning area size | 650mm(L) × 600mm(W) × 160mm (H) 3 layers |

Power / air source | 380V / 15kw (rated power) / 0.45mpa-0.7mpa |

Spray tank capacity | 20L |

Tank heater power | 9KW |

Cleaning time | 0 ~ 99 minutes (adjustable) |

Cleaning temperature (liquid) | Normal temperature - 75 ℃ (adjustable) |

Rinse time | 1 min / time (1-59 times / adjustable) |

Rinsing temperature (DI water) | Normal temperature - 55 ℃ (adjustable) |

Drying time | 0 ~ 99 minutes / (adjustable) |

Monitoring range of resistivity meter | 0~18MΩ |

Solvent tank heater power | 9KW |

Weight | 600kgs |

Detail Pictures

Related Product

Packing&Delivery

Company Profile

Shenzhen Oubel Technology Co.,Ltd.

Oubel supplies the dispensing and PCB conformal coating machine, SMT &DIP machines that is supported by a global service network,we offer customer-inspired solutions in a range of industries. OUBEL is dedicated to making quality products that help our clients operate more efficiently and effectively. Oubel is guided by the principles of fairness to our suppliers, associates,clients and employees, and helping them achieve to the best of their potential.

Clients feedback

FAQ

1.Are you a trade company or a manufacture?

We are a manufacturer,OEM & ODM service are available.

2.What is your delivery date?

The delivery date is about 3-5 days after receipt of payment.

3.What is your payment terms?

Accept payment by T/T,Paypal,Alibaba.

4.Can you provide a whole line solution?

Yes, we can.We can supply SMT line,Coating line,DIP line and LED production line.

We are a manufacturer,OEM & ODM service are available.

2.What is your delivery date?

The delivery date is about 3-5 days after receipt of payment.

3.What is your payment terms?

Accept payment by T/T,Paypal,Alibaba.

4.Can you provide a whole line solution?

Yes, we can.We can supply SMT line,Coating line,DIP line and LED production line.

Contact Us

We Recommend

New Arrivals

New products from manufacturers at wholesale prices