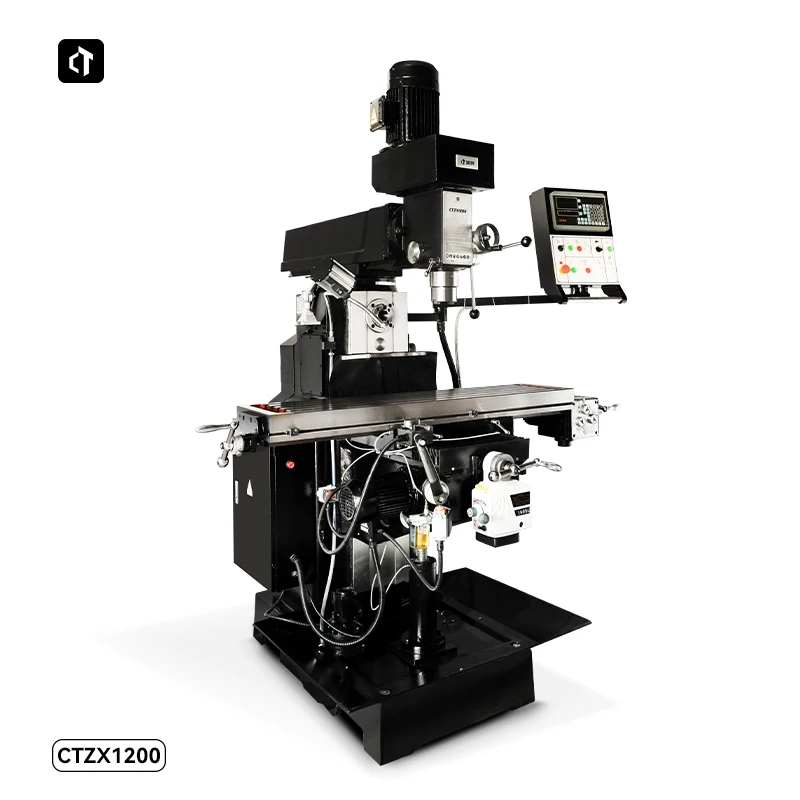

factory direct sales CTZX1200 Universal milling machine

- Category: >>>

- Supplier: Anhui Citie Technology Co. Ltd.

Share on (1600755233856):

Product Overview

Description

Features

Vertical and horizontal drilling and milling machine, equipped with three-axis grating digital display, cooling, lubrication and lighting systems. The worktable can be automatically fed, the vertical and horizontal spindle gears can be changed, the torque is large, the stability is good, and it can be used for large milling. High-precision grinding of all-steel spindle, ductile cast iron, and the shaft hole of the spindle box through fine boring, honing and internal stress relief treatment to ensure long-term and durable accuracy. With dovetail guide rails, built-in inserts, adjustable slack, and wear-resistant.

Product specifications

Spindle Taper | ISO40 |

Max. Drilling Diameter | 50/30mm |

Distance from Spindle to Worktable | 100-550mm |

Distance from Spindle to Column | 0-400mm |

Horizontal Spindle Speed | 115-1750rpm(8) |

Vertical Spindle Speed | 40-1300rpm(12) |

Spindle Travel | 120mm |

Max. Tapping Capacity | M16 |

Max. Milling Capacity | 120mm |

Spindle Rotates | 45° |

Worktable Size | 1200*280mm |

X Axis Travel | 680mm |

Y Axis Travel | 320mm |

Z Axis Travel | 450mm |

Y Axis Feed | 24-720mm/min(8) |

X Axis Feed | 1180mm/min |

Max. Loading | 300kg |

T Slot | 14mm*5 |

Horizontal/Vertical Main Motor | 1.5kw/2.2kw |

X Axis motor | 370w |

X Axis motor | 750w |

Net Weight | 1250kg |

Machine Size | 1660*1340*2150mm |

Vertical

End mills, machine-clamped cutterheads, drills, etc. can be used, tapping, drilling, keyway milling, plane milling, boring, etc.

Horizontal

The horizontal lift table milling machine can process various planes, slopes, grooves, etc. with various cylindrical milling cutters, disc milling cutters, angle milling cutters, forming milling cutters and end milling cutters.

It can process special-shaped parts such as gears, cams, arc grooves and helical surfaces. It is equipped with milling machine accessories such as universal milling head, circular table, and indexing head. After using boring bars, it can also process holes for medium and small parts.

It can process special-shaped parts such as gears, cams, arc grooves and helical surfaces. It is equipped with milling machine accessories such as universal milling head, circular table, and indexing head. After using boring bars, it can also process holes for medium and small parts.

Size/Weight

The appearance/package size of the product is measured manually, and there is a small error. It is normal, and the specific object shall prevail.

Machine package size 1810x1490x2300mm

Net weight/gross weight of machine(excluding floor cabinet) 1250/1350KG

Machine package size 1810x1490x2300mm

Net weight/gross weight of machine(excluding floor cabinet) 1250/1350KG

Identification

A. Vertical Spindle Motor

B. 3-Axis DRO

C. Vertical Spindle Speed Selectors

D. Coarse Downfeed Lever

E. Fine Downfeed Handwheel

F. Vertical Spindle

G. Ram Lock Handle (1 of 2)

H. Control Panel

I. LED Work Light

J. Coolant Nozzle

K. Horizontal Spindle

B. 3-Axis DRO

C. Vertical Spindle Speed Selectors

D. Coarse Downfeed Lever

E. Fine Downfeed Handwheel

F. Vertical Spindle

G. Ram Lock Handle (1 of 2)

H. Control Panel

I. LED Work Light

J. Coolant Nozzle

K. Horizontal Spindle

L. X-Axis Handwheel

M. X-Axis Table Lock(1 of 2)

N. Horizontal Spindle Speed Selectors

O. X-Axis Handwheel

P. Z-Axis Crank

Q. X-Axis Power Feed

R. Y-Axis Handwhee

S. Y-Axis Power Feed

T. Y-Axis Table Lock(1 of 2)

U. Base

M. X-Axis Table Lock(1 of 2)

N. Horizontal Spindle Speed Selectors

O. X-Axis Handwheel

P. Z-Axis Crank

Q. X-Axis Power Feed

R. Y-Axis Handwhee

S. Y-Axis Power Feed

T. Y-Axis Table Lock(1 of 2)

U. Base

Product display

Details introduce

Vertical milling

Spindle taper MT4 / motor 1.5KW / 8 kinds of speed 115-1750rpm

Spindle taper MT4 / motor 1.5KW / 8 kinds of speed 115-1750rpm

Horizontal milling

Spindle taper MT4 / motor 2.2KW / 12 kinds of speed 40-1300rpm

Spindle taper MT4 / motor 2.2KW / 12 kinds of speed 40-1300rpm

A. Start switch

B. Vertical milling forward button

C. End milling stop button

D. End milling reverse rotation button

E. Cooling rotary switch "O" "I"

F. Emergency stop switch

G. Horizontal milling forward button

H. Horizontal milling stop button

I. Horizontal milling reverse button

J. Workbench up button

K. Workbench down button

B. Vertical milling forward button

C. End milling stop button

D. End milling reverse rotation button

E. Cooling rotary switch "O" "I"

F. Emergency stop switch

G. Horizontal milling forward button

H. Horizontal milling stop button

I. Horizontal milling reverse button

J. Workbench up button

K. Workbench down button

Oversized worktable 1200*280mm, T-slot 5*14mm

X-axis mechanical automatic feed, 8-speed gear shifting

Y-axis Electronic tool feeder

Z-axis automatic lift

Tip: When the hand crank handle is installed on the lift table, and the handle is operated to lift the worktable, the automatic lift function will fail.

Y-axis Electronic tool feeder

Z-axis automatic lift

Tip: When the hand crank handle is installed on the lift table, and the handle is operated to lift the worktable, the automatic lift function will fail.

Standard Accessories(Attached in Machine)

Drill chuck, drill chuck key, reducer sleeve, connecting rod, oil pot, return cutter, hex wrench,T bolt

SALES AND SERVICE NETWORK

Products are exported to more than 30 countries and regions in the world

EU CE standard, safe and reliable

ISO9001 quality system certification

EU CE standard, safe and reliable

ISO9001 quality system certification

COMPANY PROFILE

FAQ

Q.What are your normal lead times?

A.Usually, we have stock of the machine, for stock machine we can send it out within 5days after got the payment. And for

customized machine need 20-30days after got the payment.

Q.What is the MOQ for your production?

A.The MOQ depends on your requirements for color, logo and so on.For some normal items, we have in stock, the MOQ is 1 set.

Q.Do you have CE certification?

A.Yes, we have CE certification.

Q: How is the Quality warranty?

A: Warranty time is 13 months after BL date. And every machine before send it out, we have quality controller to test the machine.

Q. Do you have technical support?

A. Yes, we have professional techinal department, they will help solve your problem at anytime.

Q.What kind of package do you offer?

A.Normally in polywood case, to make sure all machines in good condition when shipping.

A.Usually, we have stock of the machine, for stock machine we can send it out within 5days after got the payment. And for

customized machine need 20-30days after got the payment.

Q.What is the MOQ for your production?

A.The MOQ depends on your requirements for color, logo and so on.For some normal items, we have in stock, the MOQ is 1 set.

Q.Do you have CE certification?

A.Yes, we have CE certification.

Q: How is the Quality warranty?

A: Warranty time is 13 months after BL date. And every machine before send it out, we have quality controller to test the machine.

Q. Do you have technical support?

A. Yes, we have professional techinal department, they will help solve your problem at anytime.

Q.What kind of package do you offer?

A.Normally in polywood case, to make sure all machines in good condition when shipping.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices