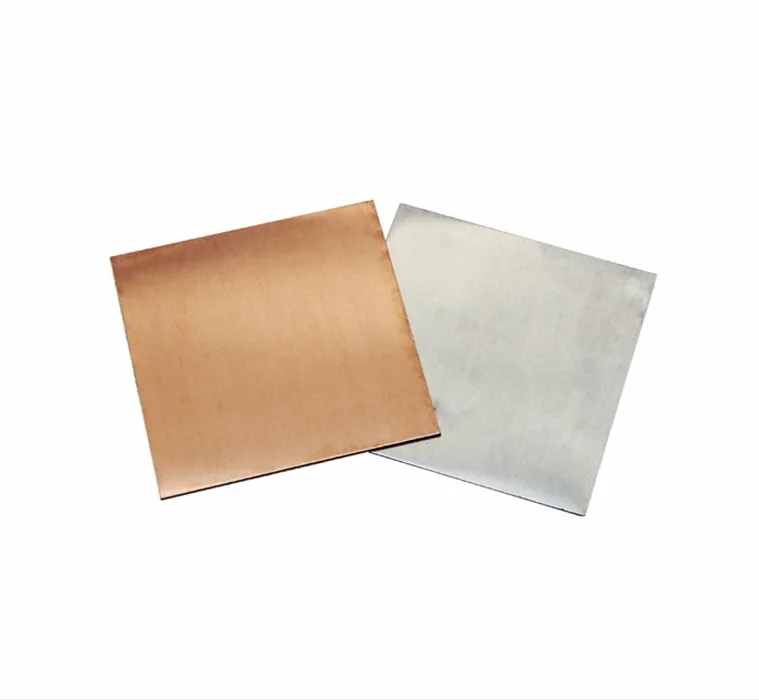

bimetallic copper aluminum washer fine copper aluminum plate sheet Copper Aluminium Plate

- Category: >>>

- Supplier: Shanghai Nansen Industry Co. Ltd.

Share on (1600764435100):

Product Overview

Description

bimetallic copper aluminum washer fine copper aluminum plate sheet Copper Aluminium Plate

With the development of lightweight and miniaturization in the electronics, communication and transportation industries, the heat dissipation problem of high energy density is becoming more and more prominent. For example, the inverter conversion of electric vehicles, PLC chip heat dissipation and high-power LED searchlight all generate huge heat in a very small volume. The traditional heat conduction materials copper and aluminum materials are difficult to meet the needs, and the cost of heat conduction and heat dissipation materials is too high to be used in industrial industrialization. Therefore, the products that can play the heat conduction properties of copper and aluminum heat dissipation properties are the materials that solve the high energy density heat dissipation.

Our company independently developed copper-aluminum composite radiator, through numerical simulation calculation, completed the simulation of copper layer thickness and aluminum layer tooth height, tooth width, tooth clearance, etc., through the company's semi-molten rolling composite process to prepare high-power copper-aluminum composite radiator. Its main characteristics are as follows

Copper-aluminum composite radiator, give full play to the thermal conductivity of copper, the heat of the heat source to derive the advantages of performance.

It gives full play to the advantages of good heat dissipation performance and light weight of aluminum, which not only realizes the miniaturization of high energy density, but also realizes the lightweight of heat dissipation system.

The metallurgical combination between copper and aluminum is realized, and there is no contact thermal resistance between copper and aluminum, which reduces the heat transfer interface and greatly improves the heat dissipation efficiency of the system.

DECORATIVE PLATE STRIP

Copper has strong corrosion resistance, beautiful appearance and color, and is widely used in decoration industry. In the decoration industry of copper strip, the main role is the outer copper, the internal copper only plays a supporting role. Our company has developed copper-aluminum composite plate strip applied in the decoration industry (curtain wall, copper door, copper plate painting, etc.) to replace pure aluminum products, which can save about 60% copper material per square meter, significantly saving precious copper resources, light aluminum material significantly reduces the processing and installation difficulty, and significantly reduces the cost of raw materials.

The product introduction is as follows: Product size: 0.6-3.0mm, width: 600-1000mm, Product features:

High composite strength, the realization of surface composite between copper and aluminum. According to different uses can adjust the material of the substrate, the state of the material, adjust the comprehensive performance of the material, to meet the requirements of different occasions, can achieve bending, drilling, deep drawing and other processing.

Technical parameters: composite strength: ≥12N/MM, composite rate: 100%, tensile strength: 130-20mpa, 90 degrees bending without crack,elongation: 0-35%

• Our products adopt the patented technology of many projects to carry out industrial continuous composite production under the condition of high temperature and high pressure without oxygen, fundamentally solving the oxidation and eutectic problems between the two metals, which not only effectively ensures the bonding strength and bonding rate between the two metals, but also guarantees the product quality and large-scale production.

• Electrochemical corrosion will not occur at the interface. When the interface is combined at high temperature and without oxygen, there will be no electrolyte formation conditions between the two metals, so electrochemical corrosion will not occur

• Continuous rolling and bright annealing processes are adopted in the follow-up processing of the products, and the quality of the products is stable

• According to the customer's use of different conditions, provide H18,H24,O state and other different states of the product

• A wide range of processing, can produce thickness between 0.02-15mm, width ≤1000mm of various specifications of products

• Widely used, can be used in electric conduction, heat conduction, anti-corrosion, decoration and other fields instead of pure copper, saving more than 80% of pure copper

Copper and aluminum are good conductor materials with high cost performance, widely used in power system, is the main conductor materials, aluminum is generally used in high-voltage lines, copper is used in low-voltage distribution cabinet system, and copper and aluminum can not be directly connected, so how to complete the reliable connection of copper and aluminum conductor has a significant impact on the safe operation of the entire power system.

The traditional Cu-Al connection equipment is usually prepared by flash welding, friction welding and other processes. The mechanical properties, reliability and electrical conductivity of the product joint have quality risks and safety risks. It is imperative to develop an advanced production process and develop a new type of electric power fittings material

Through independent innovation, our company has developed copper aluminum composite equipment wire clamp, mergers and acquisitions wire clamp, copper aluminum composite transition plate, copper aluminum composite connection gaskets, which are widely used in the power industry, instead of the traditional process, that is to improve the product quality, has reduced the production cost, is an ideal copper aluminum transition connection products

• Composite high strength, realize the metallurgical combination between copper and aluminum, solve the copper and aluminum joint low conductivity, low mechanical strength, poor reliability, low density, cost saving and resources

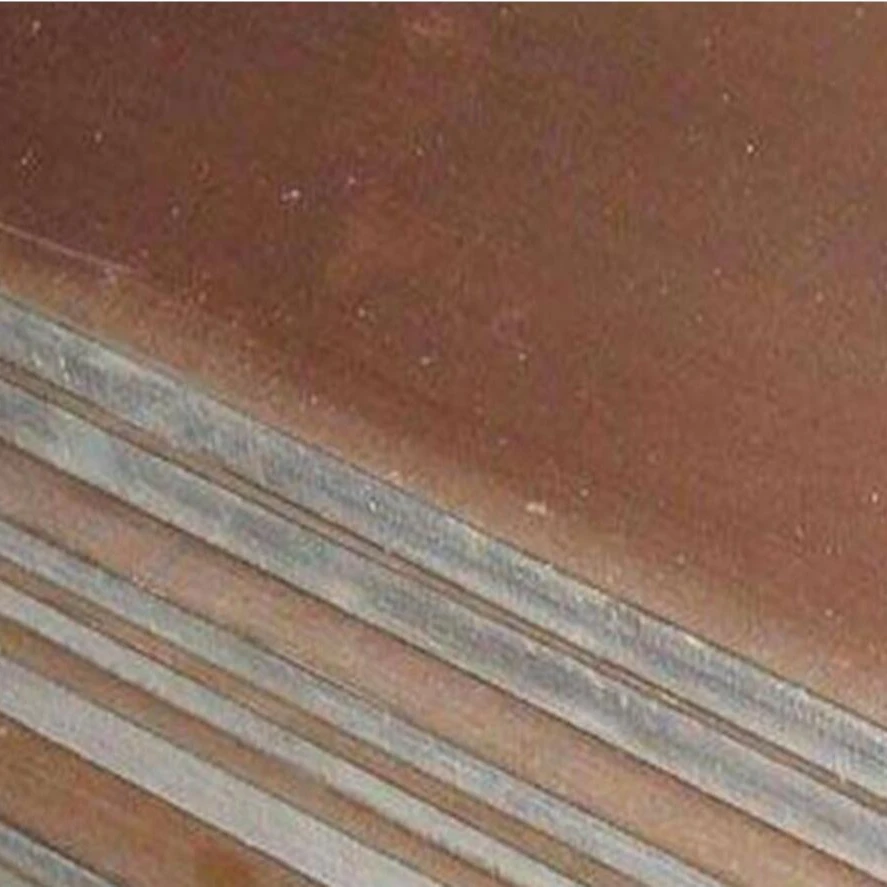

Copper - aluminum composite row product dimensions

• Thickness: 3.0~15.0mm

• Width :≤1000mm

• Technical parameters of Cu - Al composite bar

• Composite strength :≥12N/mm

• Shear strength :≥35MPa

• Tensile strength: 90~150MPa

• Elongation: 0~35%

• recombination rate: 100%

• DC resistivity: ≤0.0245Ω•mm2/m

• surface conductivity: ≥98%

• rated current temperature rise: ≤65C

• COMPANY SPIRIT & BUSSINESS PHILOSOPHY

The company has strong technical strength, advanced production technology, research base area of more than 1000 square meters, more than 400 square meters of experimental testing equipment, the total value of more than 5 million yuan, the company is a national draft unit, has obtained 6 patents for invention, utility model patents, provincial and ministerial scientific and technological achievements, the company develops copper and aluminum composite products, etc. Applied in electronic information, computer communication, LED lighting, lithium batteries for new energy vehicles and other key fields, the products replace imports, fill the domestic gap, exported to more than 20 provinces and autonomous regions, some exports to the European Union, South Korea, India and other countries and regions, the domestic market share of more than 30%, reduce enterprise costs, provide economic benefits, save resources for the country, Save energy and materials.

The company adheres to the operation philosophy of "integrity-based, customer first, realistic and innovative, dare to be the first", centering on the goal of sustainable development, to create an international famous brand, and constantly improve ourselves, with superb technology, excellent brand, excellent team, first-class service to meet the needs of our customers, and join hands with you to create a better future of metal composite materials

Ms.Monica

Shanghai Nansen Industry Co., Ltd.

Address: Pudong District, Shanghai, China.

Tel: 86-21-2024 9001

Wechat /what'app : 0086-13817208624

Email: sales at nansencn. com

Website: www.nansen-bimetal.com

We Recommend

New Arrivals

New products from manufacturers at wholesale prices