SpiderD38 Venting Valve IP 68 Chemical Plastic Dust Tight Vented Liquid Packaging Balance Boltvent Cap Seal vent bottle cap seal

- Category: >>>

- Supplier: Spider (Xiamen) Technology Co. Ltd.

Share on (1600796281756):

Product Overview

Description

FEATURES AT A GLANCE

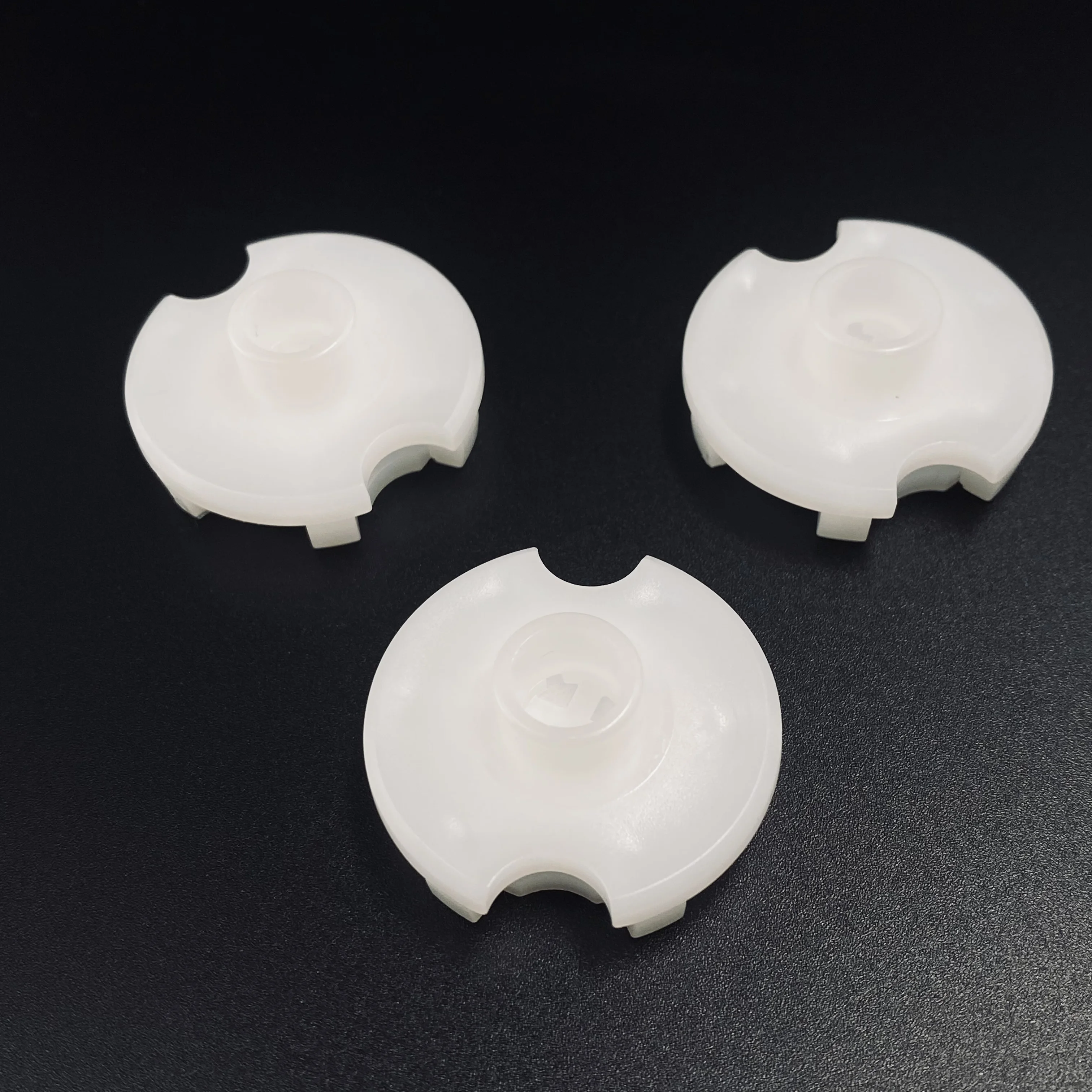

Spider Custom Pressure Relief Oleophobic D38 Air Packaging Vent Valve Plug

Color | white | |||||

Physical | D38,Air Permeable,Dustproof,Waterproof,Oleophobic,Sealing | |||||

OEM,ODM Service | Available | |||||

Product Parameters | ||||||

Product Name | Waterproof D38 Air Vent Plug | IP Rate | IP 68 | |||

Material | Plastic+ePTFE | Oil Rate | 6 | |||

Specification | 37.5*22mm | Water entry pressure | -120mbar(>1M) | |||

Airflow | 917.1ml/min ;(p=1.25mbar) | Temperature | -40 to +125℃ | |||

* Waterproof D38 Air Vent Plug

SST-Porous@ Breather Plug in vents, made of modified oleophobic ePTFE membrane and welded to HPTE parts by ultrasonic orthermal melt, having the characteristic of simple design, easy assemly and long service life.SST-Porous@Breather Plug in vents, apply press fit design, easy to combine with custom products.Standard :

D10.D15,D17.D38

SST provide customized sizes of plug and specia-shaped plug to meet your specific requirement

Design

How pulp induction liners work?

Gas passes through the microporous E-PTFE membrane ,diffuses through the pulp layer and is directed to the cap threads.Pulp

induction liners do not require a hole in the cap and can be optimized to vent with minimal vapor loss.

induction liners do not require a hole in the cap and can be optimized to vent with minimal vapor loss.

Question 1:Do your packagings suffer bloating,swelling even bursting problems?

Question 2:Are you looking for a simple ,effective and reliable venting solution?

Question 3:Do you want to work with the leader supplier in the venting market?

Question 2:Are you looking for a simple ,effective and reliable venting solution?

Question 3:Do you want to work with the leader supplier in the venting market?

Suggestions for Storage and Transportation: The liner material is sensitive to heat. A high-temperature environment will damage

the liner and affect its performance. Therefore, it can only withstand short-term storage at 0-40℃. If it needs to be used for a long time, we recommend liners and caps with liners be placed indoor with temperature between 5-35℃ and humidity between 30%-75%.

Otherwise, liners will curl and deform, and the aluminum foil will be separated from the paperboard, making it unusable.

Handling Method: If the storage site does not meet the above requirements, please place these liners in an environment where the

temperature is between 15℃-30℃ for 48 hours before use, and then decide whether to actually use them based on liner conditions.

the liner and affect its performance. Therefore, it can only withstand short-term storage at 0-40℃. If it needs to be used for a long time, we recommend liners and caps with liners be placed indoor with temperature between 5-35℃ and humidity between 30%-75%.

Otherwise, liners will curl and deform, and the aluminum foil will be separated from the paperboard, making it unusable.

Handling Method: If the storage site does not meet the above requirements, please place these liners in an environment where the

temperature is between 15℃-30℃ for 48 hours before use, and then decide whether to actually use them based on liner conditions.

Technical FAQs:

1. Q: What are the main applications of breathable liner?

A: Mainly used in chemical, agricultural, food and other packaging fields

2. Q: How to choose the breathable liner?

A: Theselection of breathable plug depends on the type of packaging liquid, sealing form, installation size, breathablerequirement andother items. Please consult the sales enginner details.

3.Q: What's the characteristic of breathable liner?

A: Dustproof, Airpermeable, leakproof.

4. Q: Will the container/bottle leak when using breather liner?

A: Generally no leaks after using breather plug, the main cause of leakage!a. Bottle/container/Buket be inverted or turned over for a long time, resulting in leakage after airtight.b. There is no hole on the outer cover, and the gas breaks through the breather membrane causing leakagec. The liquid's surface tension is too low, causing leakage.

5. Q: How about the acid and alkali resistance of the breather liner??

A: Therecommended PH is 5 to 9 for conventiongl liner.

Application Case

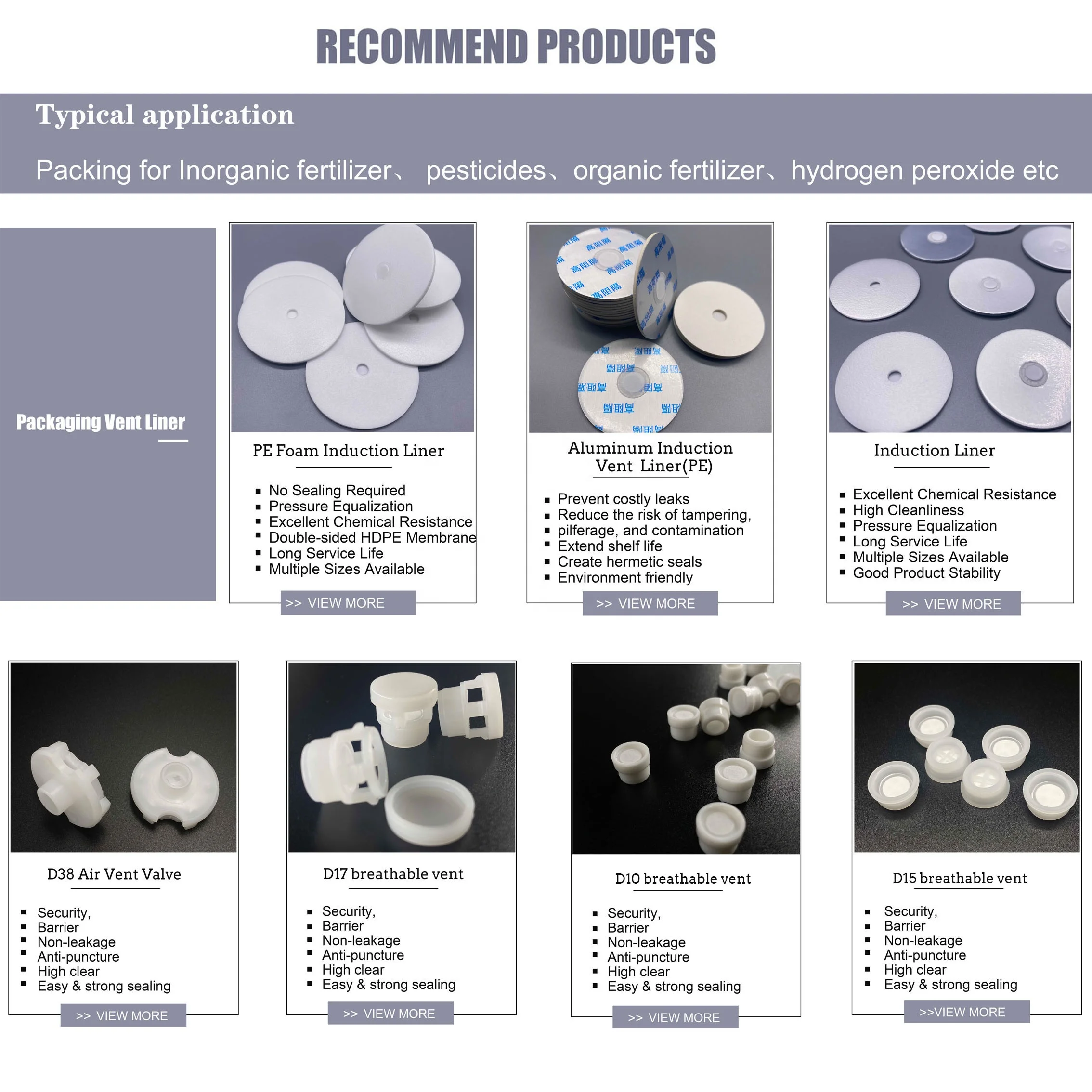

Typical application: packing for Inorganic fertilizer、 pesticides、organic fertilizer、hydrogen peroxide etc

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Our advantages

2.10~20% of the company's revenue is used for new product R&D, design, analysis, test, technical consulting expenses, intellectual property protection.

3.A number of independent intellectual property rights, as well as product registered trademarks.

Payment & Logistics

FAQ

We Recommend

New Arrivals

New products from manufacturers at wholesale prices