Automatic PCBA Cleaning Machine Smt Cleaning Machine Smt Nozzle Cleaner Pcba Cleaning Equipment

- Category: >>>

- Supplier: Shenzhen Yufuxin Technology Co. Ltd.

Share on (1600798049483):

Product Overview

Description

Product Description

This equipment is mainly used for the cleaning of assembly parts and semiconductor flux residues in the electronics industry. The

water-based cleaning machine is used for spray cleaning to remove surface flux residues, solder balls, solder paste, dust,

impurities, oil and other pollutants. Clear. Rinse with deionized water to make the product 100% clean, without any safety

hazards, and harmless to humans and the environment.

Standard cleaning process:

Into the board → pre-cleaning → cleaning → chemical isolation → pre-rinsing → rinsing → rinsing Ⅱ → last spraying → air knife

cutting water Ⅰ → air knife cutting water Ⅱ → hot air circulation drying → board exit

Machine characteristics:

The whole machine is made of 304 stainless steel, which is durable and resistant to acid, alkali and other cleaning fluids.

Suitable for large batches of PC B A to complete all processes of washing, rinsing and drying online

Excellent cleaning effect, effectively remove rosin, water-soluble flux, no-clean flux

Organic and inorganic pollutants

Unique chemical isolation method, lower running cost

PC B A of different sizes can be cleaned

Resistivity monitoring rinsing liquid to ensure product cleanliness

The nozzle pressure can be adjusted to meet the cleaning pressure range of different products

All heating temperatures can be adjusted

Air knife cutting water + ultra-long hot air circulation drying section

Optional spray cleaning knife for better cleaning effect

Large-size color touch screen automation control, Chinese / English operation interface, for different

Quickly edit and save product cleaning process parameters

Flexible running of water or chemical cleaning

Unique rinsing overflow design, saving water consumption

U PS backup power supply system

Short delivery cycle

Localized service team and sufficient spare parts supply

water-based cleaning machine is used for spray cleaning to remove surface flux residues, solder balls, solder paste, dust,

impurities, oil and other pollutants. Clear. Rinse with deionized water to make the product 100% clean, without any safety

hazards, and harmless to humans and the environment.

Standard cleaning process:

Into the board → pre-cleaning → cleaning → chemical isolation → pre-rinsing → rinsing → rinsing Ⅱ → last spraying → air knife

cutting water Ⅰ → air knife cutting water Ⅱ → hot air circulation drying → board exit

Machine characteristics:

The whole machine is made of 304 stainless steel, which is durable and resistant to acid, alkali and other cleaning fluids.

Suitable for large batches of PC B A to complete all processes of washing, rinsing and drying online

Excellent cleaning effect, effectively remove rosin, water-soluble flux, no-clean flux

Organic and inorganic pollutants

Unique chemical isolation method, lower running cost

PC B A of different sizes can be cleaned

Resistivity monitoring rinsing liquid to ensure product cleanliness

The nozzle pressure can be adjusted to meet the cleaning pressure range of different products

All heating temperatures can be adjusted

Air knife cutting water + ultra-long hot air circulation drying section

Optional spray cleaning knife for better cleaning effect

Large-size color touch screen automation control, Chinese / English operation interface, for different

Quickly edit and save product cleaning process parameters

Flexible running of water or chemical cleaning

Unique rinsing overflow design, saving water consumption

U PS backup power supply system

Short delivery cycle

Localized service team and sufficient spare parts supply

Cleaning maximum size | 550mm(W)*100mm(H) |

Minimum cleaning size | 10mm(W)*10mm(H)Fixture |

Height of conveying surface from ground | 900±50mm |

Working width | 300mm |

transfer speed | 10cm~150cm/min(adjust) |

transfer method | Mesh belt conveyor |

Conveying direction | Left in right out |

Filtration accuracy | 0.22um |

Cleaning tank capacity | 300L |

Cleaning water pump power | 7.5kw |

Heating power of cleaning tank | 27kw |

Rinse tank capacity | 200L |

Packing & Delivery

vacuum packing and wooden case

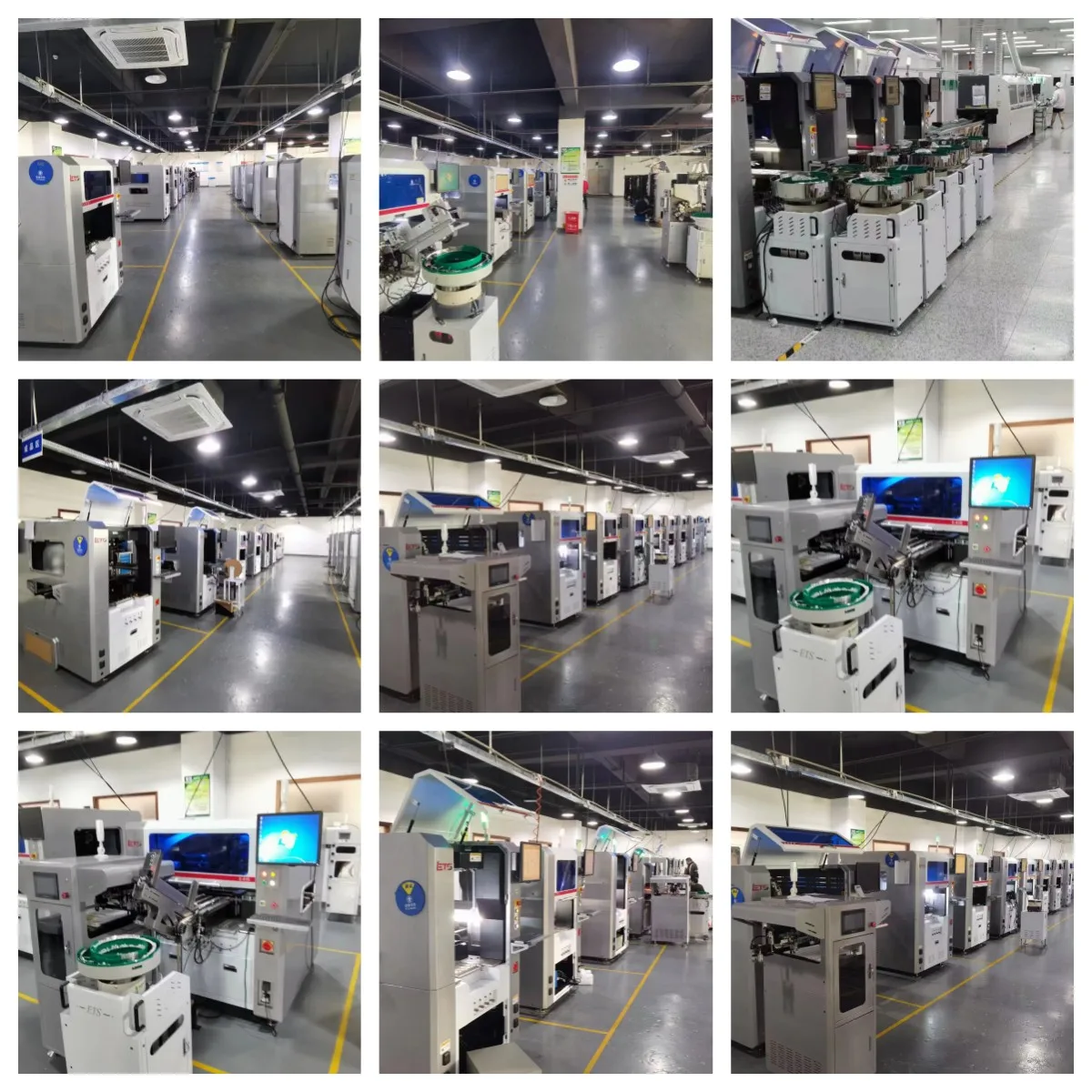

Company Profile

Shenzhen Yufuxin Technology Co., Ltd. is highly regarded for its world-class quality products, produced with the flexibility and nimbleness demanded by its customers all over the world.Under your witness, we will continue to work hard, strive for innovative research and development of more advanced equipment.

FAQ

Q: What's your main service?

A: We provide total SMT machines and soluton service, professional technology support and after sales.

Q: Are you a trade company or a manufacture?

A: We are an experienced manufacturer of SMT and PCBA equipment, OEM & ODM service are available.

Q: What is your delivery date?

A: The delivery date is about 35 days after receipt of payment.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Q: Can you provide a whole line solution?

A: Yes, We can supply SMT line, Coating line, DIP line and LED production line.

A: We provide total SMT machines and soluton service, professional technology support and after sales.

Q: Are you a trade company or a manufacture?

A: We are an experienced manufacturer of SMT and PCBA equipment, OEM & ODM service are available.

Q: What is your delivery date?

A: The delivery date is about 35 days after receipt of payment.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Q: Can you provide a whole line solution?

A: Yes, We can supply SMT line, Coating line, DIP line and LED production line.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices