Factory Price HEIC Roller Impact Compact Roller for Ground Improvement in Singapore

- Category: >>>

- Supplier: Sinoway Industrial (Shanghai) Co. Ltd.

Share on (1600807155259):

Product Overview

Description

Products Description

Impact rollers, also known as impact compactor rollers, earth rollers and impact compactors are a new type of traction roller with high energy power.

The impact roller is pulled by construction tractor or other devices and drives the impact wheels. By the weight of the impact wheel itself and the impact force during the forward process, the cement road and roadbed are crushed and compacted.

The development and application of impact rollers have accelerated the development of geotechnical compaction technology, providing new ideas for solving the quality hazards of roadbed: effectively reducing post construction settlement of roadbed and ensuring the overall stability of embankment; The roadbed and embankment of the formed roadbed were inspected and added to the inspection, improving the overall strength and uniformity of the roadbed. Pre fill the collapsible loess foundation or weak foundation to meet the requirements of bearing capacity and stability; The impact crushing technology transformation of old roads such as crushed stone pavement and cement concrete pavement can accelerate the construction progress and meet the engineering quality requirements. At present, almost all developed and developing countries have applied impact rolling technology.

Advantages of Impact Rolling Compaction Technology

The impact roller uses non-circular wheels, normally are 3-sided, 4-sided and 5-sided impact drums, to carry out static

pressure,enthalpy and periodic impact on earth rock materials along the ground, and produces strong shock waves with seismic wave propagation characteristics downward. Taking the impact compaction of a 25kJ trilateral double wheel impact roller on a slag gravel roadbed as an example, after driving at a speed of 15km/h for 30 times, the average vertical soil pressure measured at a depth of 0.8m is 1366kPa, which is equivalent to an impact force generated on the ground of 200t~250t. The impact function is overweight compaction work, which can improve the compaction degree of deep underground soil and increase the compaction degree to over 90% of the heavy standard. The effective compaction thickness of some soil and rock materials is 1.5 meters, which has better compaction effect than existing vibration compaction machinery, making the compacted soil and rock fill closer to the elastic state.

Compared to traditional road rollers, impact rollers have different compaction processes. Basically, it does not use existing road rollers or partial overlapping compaction construction methods, but instead uses the directional behavior of impact force spreading towards the deep soil layer, and proposes a new impact mill. Pressurization methods and construction techniques. The width of both sides of the impact roller is 0.9 meters, and the inner circumference of the two wheels is 1.17 meters. Drive twice, with a punching width of 4 meters. Each impact force is applied at (45 °- Φ/ 2) When the angle of is distributed on the soil mass roller. The second round of each pass passes through the center of the inner edges of the first two rounds, forming a the oretical punching gap of 0.13 meters each. When the second pass moves back 0.2m, all gaps in the first pass roll. Restore the third path to the position of the first path and proceed to the last path in sequence. Various types of soil and stone roadbed can be ground 20 to 40 times to form a uniform reinforcement layer with a thickness of 1.0m to 1.5m.

Uses and applications

▪ Residential Subdivisions

▪ Civil and

▪ Mining Infrastructure

▪ Industrial & Commercial

▪ Container Terminals

▪ Airports

We can offer brand new trilateral impact rollers and Pentagon Impact rollers with 25 Kj to 35 Kj energy force.

The impact roller is pulled by construction tractor or other devices and drives the impact wheels. By the weight of the impact wheel itself and the impact force during the forward process, the cement road and roadbed are crushed and compacted.

The development and application of impact rollers have accelerated the development of geotechnical compaction technology, providing new ideas for solving the quality hazards of roadbed: effectively reducing post construction settlement of roadbed and ensuring the overall stability of embankment; The roadbed and embankment of the formed roadbed were inspected and added to the inspection, improving the overall strength and uniformity of the roadbed. Pre fill the collapsible loess foundation or weak foundation to meet the requirements of bearing capacity and stability; The impact crushing technology transformation of old roads such as crushed stone pavement and cement concrete pavement can accelerate the construction progress and meet the engineering quality requirements. At present, almost all developed and developing countries have applied impact rolling technology.

Advantages of Impact Rolling Compaction Technology

The impact roller uses non-circular wheels, normally are 3-sided, 4-sided and 5-sided impact drums, to carry out static

pressure,enthalpy and periodic impact on earth rock materials along the ground, and produces strong shock waves with seismic wave propagation characteristics downward. Taking the impact compaction of a 25kJ trilateral double wheel impact roller on a slag gravel roadbed as an example, after driving at a speed of 15km/h for 30 times, the average vertical soil pressure measured at a depth of 0.8m is 1366kPa, which is equivalent to an impact force generated on the ground of 200t~250t. The impact function is overweight compaction work, which can improve the compaction degree of deep underground soil and increase the compaction degree to over 90% of the heavy standard. The effective compaction thickness of some soil and rock materials is 1.5 meters, which has better compaction effect than existing vibration compaction machinery, making the compacted soil and rock fill closer to the elastic state.

Compared to traditional road rollers, impact rollers have different compaction processes. Basically, it does not use existing road rollers or partial overlapping compaction construction methods, but instead uses the directional behavior of impact force spreading towards the deep soil layer, and proposes a new impact mill. Pressurization methods and construction techniques. The width of both sides of the impact roller is 0.9 meters, and the inner circumference of the two wheels is 1.17 meters. Drive twice, with a punching width of 4 meters. Each impact force is applied at (45 °- Φ/ 2) When the angle of is distributed on the soil mass roller. The second round of each pass passes through the center of the inner edges of the first two rounds, forming a the oretical punching gap of 0.13 meters each. When the second pass moves back 0.2m, all gaps in the first pass roll. Restore the third path to the position of the first path and proceed to the last path in sequence. Various types of soil and stone roadbed can be ground 20 to 40 times to form a uniform reinforcement layer with a thickness of 1.0m to 1.5m.

Uses and applications

▪ Residential Subdivisions

▪ Civil and

▪ Mining Infrastructure

▪ Industrial & Commercial

▪ Container Terminals

▪ Airports

We can offer brand new trilateral impact rollers and Pentagon Impact rollers with 25 Kj to 35 Kj energy force.

Machine Show

Product Paramenters

Specification of Tractor | ||

Tractor model | SWT360 | |

Operating weight | 16000kg | |

Engine make | WEICHAI | |

Rated power | 266kw | |

Overall dimension | 5975 x 2750 x 3320mm | |

Turning radius (outside) | 5800mm | |

Min. ground clearance | 360mm | |

Wheelbase | 3000mm | |

Fuel tank | 444L | |

Peak traction | I:126KN, II:106KN | |

Gradeability | 6% - 60% | |

Travel speed (F) | I: 0 - 8.4km/h, II: 0 - 15.2km/h, III: 0 - 29km/h | |

Travel speed (R) | I: 0 - 10km/h | |

Tire size | 23.5-25-16PR | |

Specification of Impact Compactor | ||

Model | SWIC320 | |

Impact power | 32KJ | |

Travelling speed | 10 - 15km/h | |

Operating weight | 14500kg | |

Gradeability | 25° | |

Compaction | 95 - 98% | |

Min. turning radius | 6000mm | |

Overall dimension | 3880 x 2980 x 2450mm | |

Tread | 1180mm | |

Width of roller | 900mm | |

Damping mode | Hydraulic, nitrogen, spring, rubber bumper | |

Pressure of accumulator | 3 - 4.5MPa | |

Pressure of tire | 0.6 - 0.8MPa | |

Shape of roller | Trilateral | |

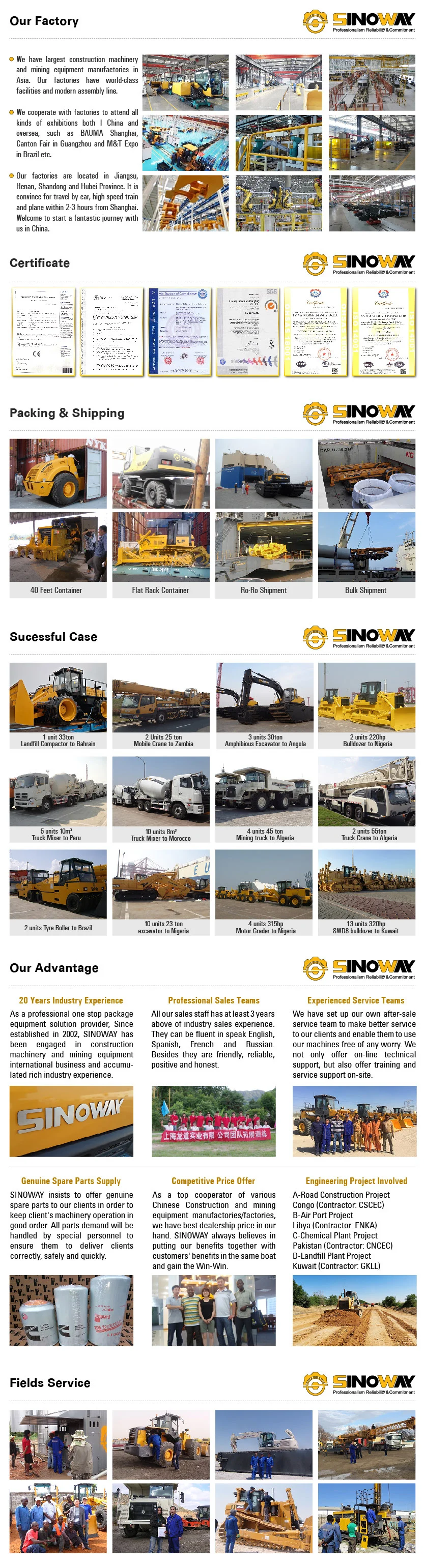

Why Choose us

We Recommend

New Arrivals

New products from manufacturers at wholesale prices