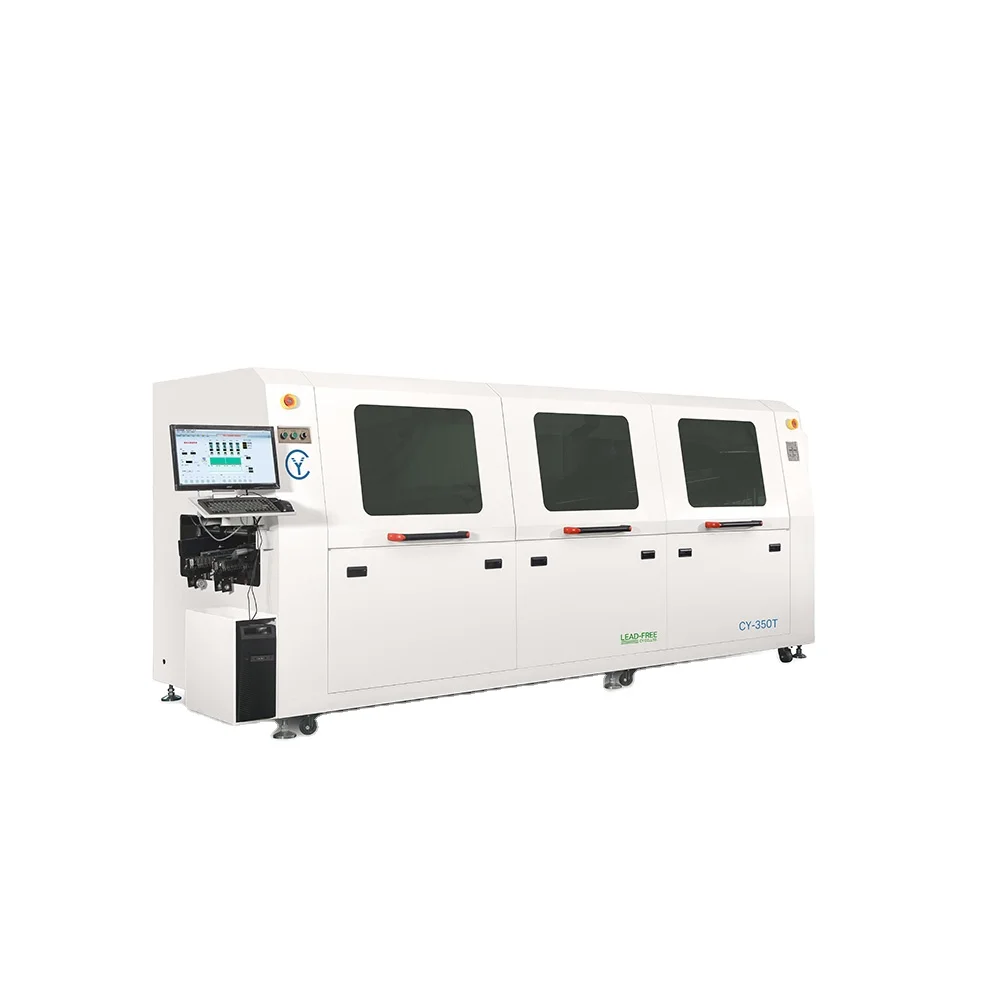

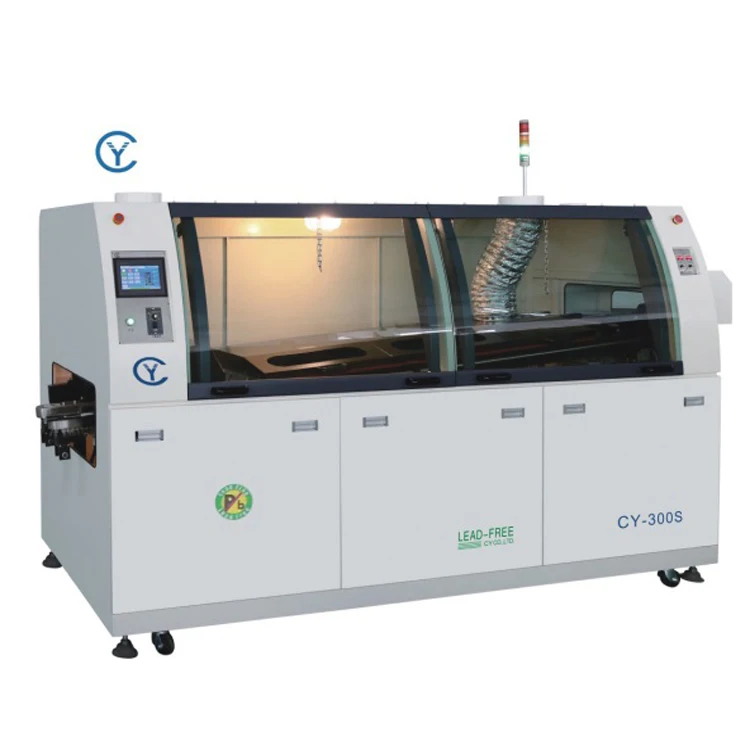

CY Pcba Full Automatic Selective For Dip Welding Equipment Wave Soldering For Electronic Products on hot sale

- Category: >>>

- Supplier: Shenzhen Chengyuan Industrial Automation Equipment Co. Ltd.Shenzhen Ltd.

Share on (1600816438061):

Product Overview

Description

Products Description

High quality PCB wave soldering machine CY-350B

Features

◆Windows7 operating system, Chinese and English interface switch, easy to operate.

◆Fault diagnosis function, can display each fault, display and store in automatic alarm list

◆Fault diagnosis function, can display each fault, display and store in automatic alarm list

◆Control procedures can automatically generate and backup the data report, easy to ISO 9000

management

◆Automatic board access device, smooth and stable.

◆Specially hardened aluminium guide rail with high hardness and strength, guarantees no deformation at

high temperature

◆4mm SUS316L imported stainless steel furnaces, new design, beautiful appearance

◆Wave automatically when board through,adjustable peak width to minimize tin oxidation

◆600mm extended two-section preheating, infrared independent PID temperature control, uniform

heating, safe and stable.

management

◆Automatic board access device, smooth and stable.

◆Specially hardened aluminium guide rail with high hardness and strength, guarantees no deformation at

high temperature

◆4mm SUS316L imported stainless steel furnaces, new design, beautiful appearance

◆Wave automatically when board through,adjustable peak width to minimize tin oxidation

◆600mm extended two-section preheating, infrared independent PID temperature control, uniform

heating, safe and stable.

Spry System

◆With Lumina (Japan) nozzle, the spray range is20-65mm, the nozzle height is 50-80mm, and the maximum flow rate is 60ml/min.

◆Uses AirTAC (Taiwan) filter, pointer gauge shows air pressure, all spray system pipes are acid and alkali resistant corrosion

protection pipes.

◆Spraying system adopts scanning spraying method, limit switch and entry eyesight are combined to control, and PCB is

automatically detected by inductive spraying according to the speed and width of PCB, so that the wetting range of flux can

achieve the best effect. Inlet spray head and stepping motor are efficient, stable and reliable.

◆Stainless steel bent forming tray is used underneath the spray head for loading wastewater and flux, which can be extracted and

cleaned at will.

◆The air extraction system is a superimposed automatic recovery system with three layers of stainless steel wire mesh filtration

to minimize residual flux blockage in the air extraction pipeline by utilizing the fluid characteristics to filter excess flux.

◆Pneumatic air knife, which blows excess flux during spraying into the recovery tank to prevent flux from entering the preheating

zone and ensure production safety.

◆All stainless steel + aluminium alloy support, easy cleaning and maintenance, strong corrosion resistance, durable.

◆Uses AirTAC (Taiwan) filter, pointer gauge shows air pressure, all spray system pipes are acid and alkali resistant corrosion

protection pipes.

◆Spraying system adopts scanning spraying method, limit switch and entry eyesight are combined to control, and PCB is

automatically detected by inductive spraying according to the speed and width of PCB, so that the wetting range of flux can

achieve the best effect. Inlet spray head and stepping motor are efficient, stable and reliable.

◆Stainless steel bent forming tray is used underneath the spray head for loading wastewater and flux, which can be extracted and

cleaned at will.

◆The air extraction system is a superimposed automatic recovery system with three layers of stainless steel wire mesh filtration

to minimize residual flux blockage in the air extraction pipeline by utilizing the fluid characteristics to filter excess flux.

◆Pneumatic air knife, which blows excess flux during spraying into the recovery tank to prevent flux from entering the preheating

zone and ensure production safety.

◆All stainless steel + aluminium alloy support, easy cleaning and maintenance, strong corrosion resistance, durable.

Heating system

"Far Infrared + Hot Air" Composite Heating Principle

◆Porous plate heater is used as the infrared heating source and the far infrared light penetration is used to

directly heat the PCB , thus avoiding the problem of insufficient heating capacity in traditional full hot air

mode.

◆Composite heating, mainly by infrared heating, supplemented by hot air convection, can improve

heating capacity and uniform heating.

◆High temperature hot air motor is imported from Sanyue (Taiwan). The heating wire is nickel winding

and its service life is greatly improved.

◆Modular pull-out design facilitates operator maintenance

directly heat the PCB , thus avoiding the problem of insufficient heating capacity in traditional full hot air

mode.

◆Composite heating, mainly by infrared heating, supplemented by hot air convection, can improve

heating capacity and uniform heating.

◆High temperature hot air motor is imported from Sanyue (Taiwan). The heating wire is nickel winding

and its service life is greatly improved.

◆Modular pull-out design facilitates operator maintenance

Soldering system

◆4mm SUS316L imported stainless steel bladder, new type of bladder design, beautiful appearance, easy cleaning, cast iron heating

plate, no deformation of the bladder

◆Adjustable peak width to minimize tin oxidation, removable without removing the nozzle

◆The position of impeller shaft increases the oxidation shield and reduces the tin oxide produced by the rotation of impeller

shaft.

◆The impeller shaft and peak motor parts can be separately removed without removing the tin track (other brand peak welding can

not do this design).

◆Tin slag oxidation: using 200*200 mm PCB plate as test plate and calculating at 300 pcs per hour, the amount of tin slag produced

in 10 hours is 2KG

plate, no deformation of the bladder

◆Adjustable peak width to minimize tin oxidation, removable without removing the nozzle

◆The position of impeller shaft increases the oxidation shield and reduces the tin oxide produced by the rotation of impeller

shaft.

◆The impeller shaft and peak motor parts can be separately removed without removing the tin track (other brand peak welding can

not do this design).

◆Tin slag oxidation: using 200*200 mm PCB plate as test plate and calculating at 300 pcs per hour, the amount of tin slag produced

in 10 hours is 2KG

Product Paramenters

Model | CY-350B | ||||||

Control method | Dell computer(Windows7)+Siemens PLC Industrial control computer+PLC | ||||||

Conveyor motor | 3∮ AC380V 90W,Tai Chuang | ||||||

Pcb size | 50-450mm(w) | ||||||

Preheating Zone | Power:16KW Length:(1800mm 4sections PID control | ||||||

Solder temperature | 9KW (Room temperature -300℃) | ||||||

Solder capacity | 400kg | ||||||

Wave motor | 3P AC 220V 0.36KW*2pcs,Brand:Taichuang | ||||||

Finger cleaning pump | 1P AC220V 6W | ||||||

Cooling system | Forced-air cooling | ||||||

PCB transport direction | L→R /(R→L) | ||||||

Nozzle move | stepper motor or SMC rodless cylinder | ||||||

Flux capacity | 6 LITRES | ||||||

Air pressure of flux | 3-5BAR | ||||||

Conveyor angle | 4-7℃ | ||||||

Power supply | 3P AC380V 50Hz | ||||||

Normal/starting power | 28KW/8KW | ||||||

Weight | 1400kg | ||||||

Cooling system | Mandatory cooling | ||||||

Dimension | 3800(L)x1360(W)x1700mm(H) | ||||||

Appearance | 4400(L)x1400(W)x1700mm(H) | ||||||

Product packaging

Company Profile

Exhibition

Chengyuan Industrial Automation Equipment Co.,Ltd

Shenzhen Chengyuan Industrial Automation Equipment Co., Ltd.

is the leading SMT factory solution provider in China,offering professional SMT factory building advice and service.With 20 year experience about SMT factories,offering full solutions for global clients with our great advantaged sources and service.

Our core technology team members are well experienced in SMT filed, learning experience from top international chip mounters meanwhile increasing independent research and development Currently

Ours SMT equipment is representative of high quality , has maintained absolute leading technology in the industry.

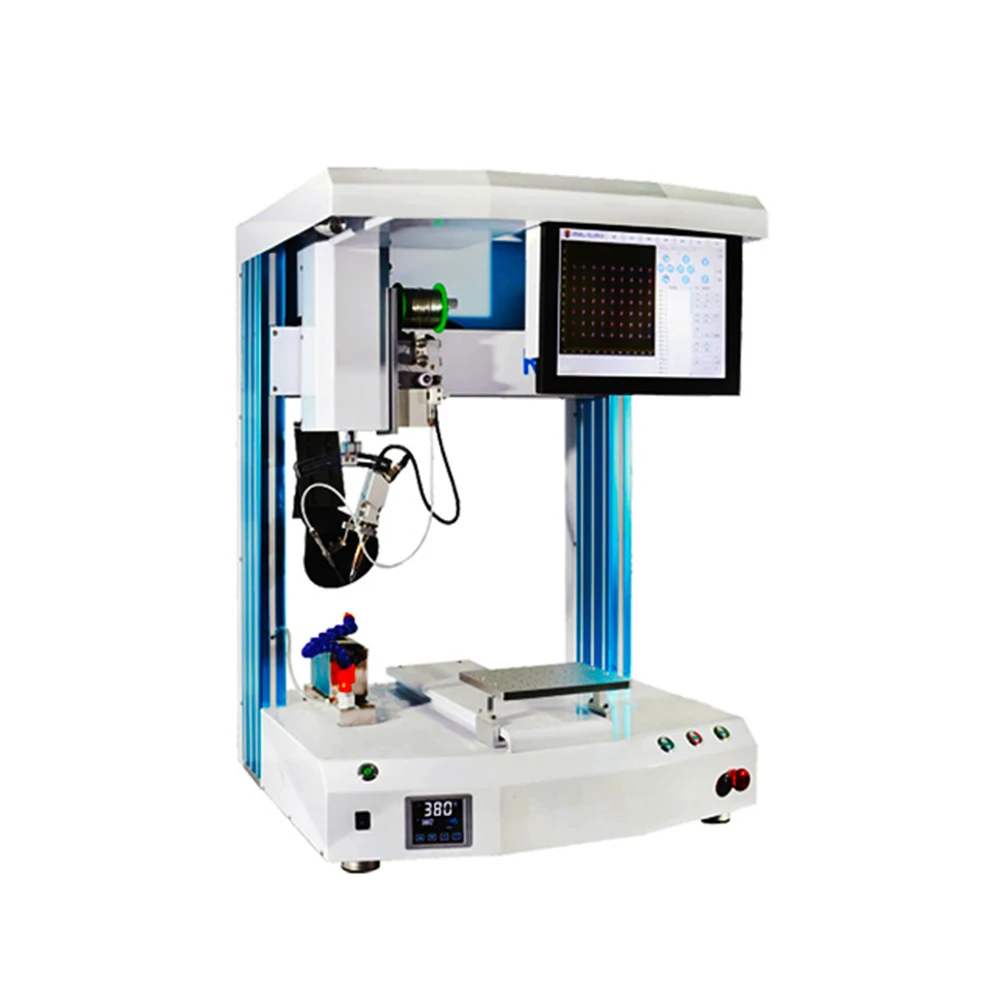

We also focuses on the research and development of fluid control equipment and dispensing systems like: selective conformal coating machine, PCB dispensing machine and related equiment such as: PCB IR curing oven,UV curing oven, Loader, Conveyors.

The equipment is mainly used in digital communication, LED, automotive electronics,

intelligent wearables, instrumentation, aerospace and other fields.

Taking Shenzhen the base, the company keeps learning the excellent resources in the industry,

actively innovates and integrates, extensively absorbs senior technical personnel, and establishes a

permanent mutual cooperative relationship with Harbin Institute of Technology on product learning,

research and development.With the continuous development and growth of the company,

the company's sales network has been throughout the country, with a number of stable agents.

Shenzhen Chengyuan Industrial Automation Equipment Co., Ltd.

is the leading SMT factory solution provider in China,offering professional SMT factory building advice and service.With 20 year experience about SMT factories,offering full solutions for global clients with our great advantaged sources and service.

Our core technology team members are well experienced in SMT filed, learning experience from top international chip mounters meanwhile increasing independent research and development Currently

Ours SMT equipment is representative of high quality , has maintained absolute leading technology in the industry.

We also focuses on the research and development of fluid control equipment and dispensing systems like: selective conformal coating machine, PCB dispensing machine and related equiment such as: PCB IR curing oven,UV curing oven, Loader, Conveyors.

The equipment is mainly used in digital communication, LED, automotive electronics,

intelligent wearables, instrumentation, aerospace and other fields.

Taking Shenzhen the base, the company keeps learning the excellent resources in the industry,

actively innovates and integrates, extensively absorbs senior technical personnel, and establishes a

permanent mutual cooperative relationship with Harbin Institute of Technology on product learning,

research and development.With the continuous development and growth of the company,

the company's sales network has been throughout the country, with a number of stable agents.

Certifications

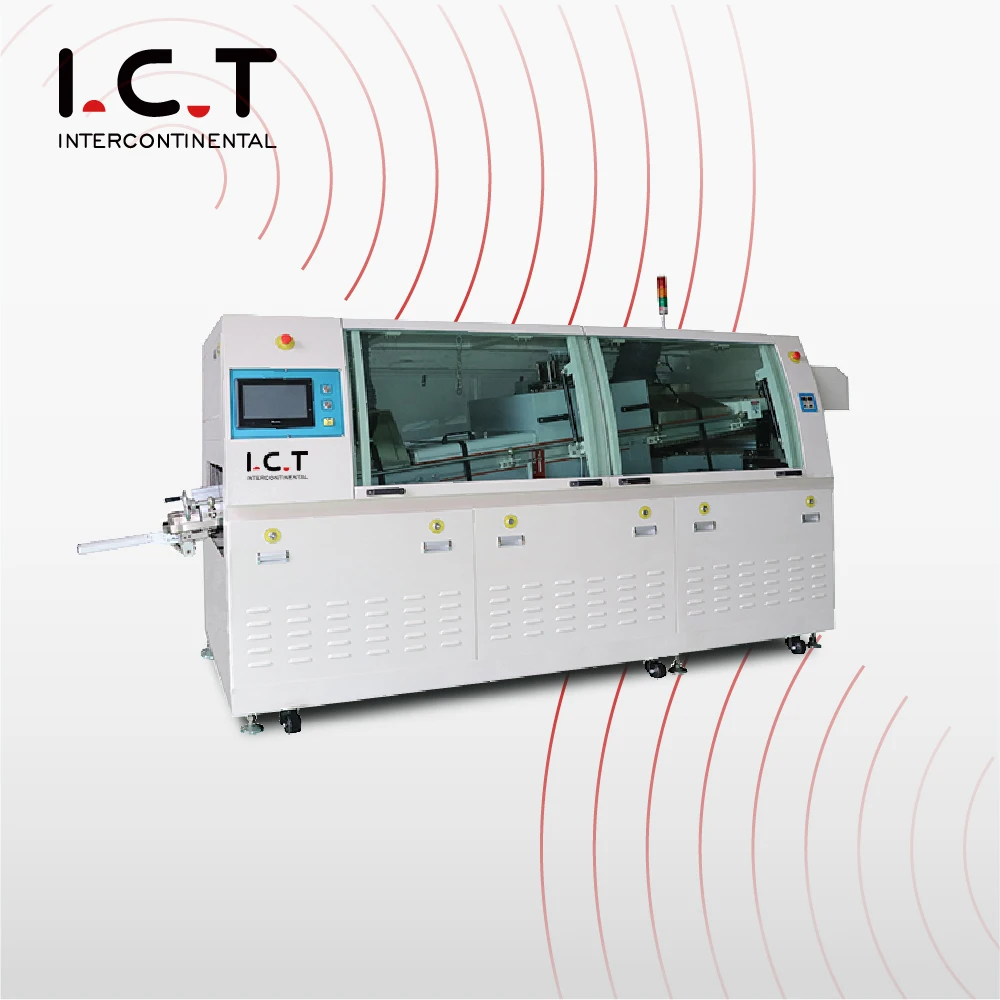

Recommend Products

We Recommend

New Arrivals

New products from manufacturers at wholesale prices