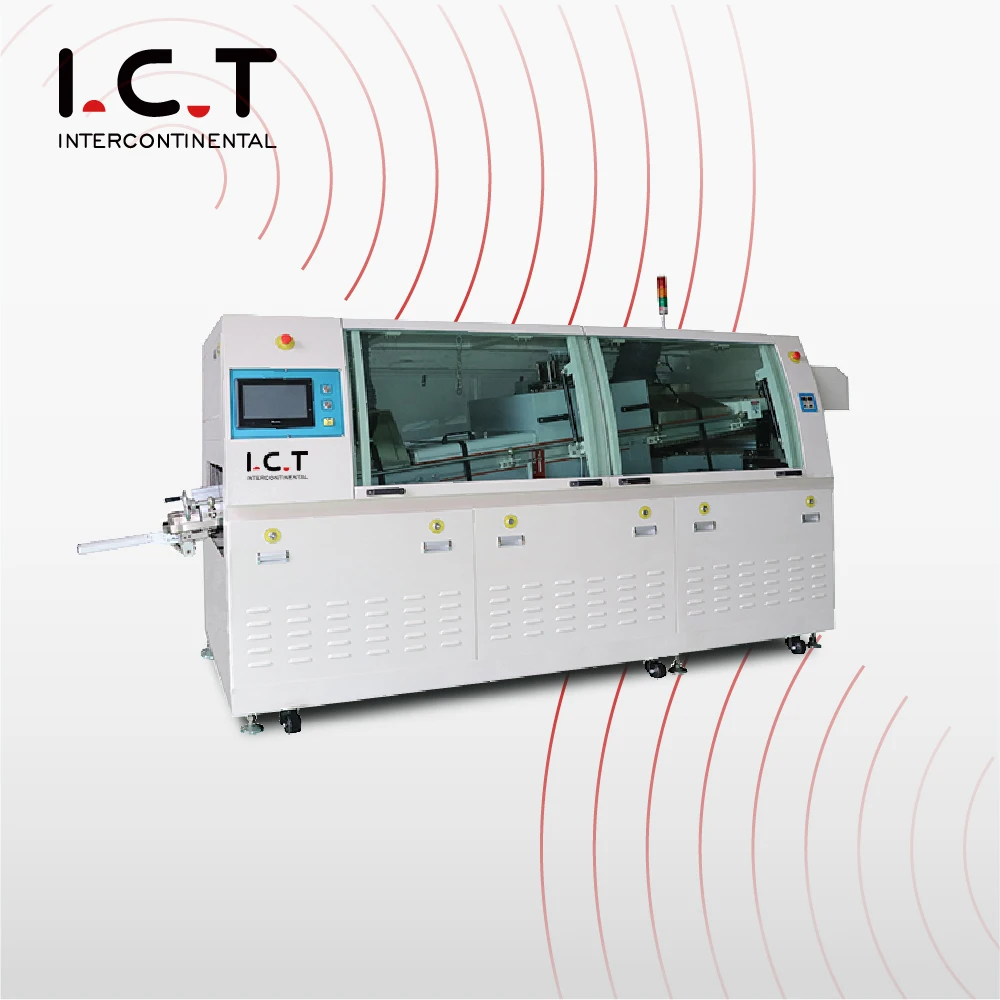

Provided 220V Automatic Selective Soldering Machine PCB Wave Soldering Machine Price Sami Auto Dip Soldering Machine 1600 Option

- Category: >>>

- Supplier: Yush Electronic Technology Co. Ltd.

Share on (1600818773645):

Product Overview

Description

Series

1. Selective sprayer, tin stove with nitrogen partially filled

2. Compatible with customer MES system

3. Horizontal designed feed plate connection, no need for tapping machine

4. The spray is far distant from preheating zone, preventing fire hazard

5. Preheating heat pipe is U-typed and its material high temperature resistant stainless steel sintered tube, with a service life of more than 12 years

6. modular design of preheating system and insulation measures are good

7. 1/2HP high power wave motor, maximum peak height up to 16mm. (optionalfor above 20MM)

8. 1KG/10HLow amount of machine tin dross

E I P Comparison table of technical parameters of EIP wave soldering series

| Dimenslion(L×VwxH) | 4550x1625x 1715mm | 4550x1885x 1715mm | 4550x1885x 1715mm |

PCB transport diirection | L--->R (R --->L Optional) | ||

| Main voltage | 3P5W380VAC, 50/60HZ 110A | 3P5W380VAC, 50/60HZ 110A | 3P5W380VAC, 50/60HZ 115A |

| Poer supply requiraments | 60KW | ||

| Air power requirements | 0.3- 0.7MPa | ||

| Total powar | 50KW | 50KW | 50KW |

| Normal pawer consurmpticn | 12.5KW | 12.5KW | 12.5KW |

| Control mathod | PC+PLC | ||

| Prehaating method | Hot air / infrared / spotlight optional | ||

| Preheatineg fan speed centrcl mode | Promise frequency control | ||

| Number of preheating zones | 4 | ||

| Pre-heat zone length | 2300mm | ||

| Pre-heat temperature | Room temperature -280 ℃ | ||

| Pra-heat temperature control | PID+SSR mode | ||

| wave running mocle | Mechanical pump | ||

| Tin furmece heat pipa powar | 1.0KW*12 | ||

| 2nIce chieiy ttin'speicific gravity | 650KG | 750KG | 820KG |

| TPithatond tomperature | MAX: 300°C | ||

| Tin furnacelimit the use of temperature | MAX: 280°C | ||

| Tin furnace control mode | PID+SSR mode | ||

| Peak drive power | 1/2HPx23P 220VAC | 1/2HP+1HP 3P 220VAC | 1/2HPx1 1HPx1 3P 220VAC |

| Crest height adjustment method | Frequency adjustment | ||

| Tin furnace heating time | 150MIN Set temperature 26°C | 180M IN Set temperature 26°C | |

| PCB transfer speed | 0- 1800mm / min | ||

| PCB board width range | 80-350mm | 80-510mm | 80-610mm |

| PCB board height | Top: 110mm Bottom: 25mm | ||

| PCB inlet transport height | 750±20mm | ||

| Transport guide inclination | The standard is fixed at 5.5, and can be adjusted by about 50 specifications | ± 0.5° | |

| Transport motor power | 90W 3P 220VAC | ||

| Transport motor speed control mode | Frequency control | ||

| Nitrogen consumption | 15m3/ h100ppm | ||

| Nitrogen gas source pressure | 0.5-0.8MPA | ||

| Nitrogen gas souroe oxygen content | 10PPM | ||

| Number of nitrogen flow meters | 3 | ||

| Suction pipe diameter | <P200mm | ||

YUSH Electronic Technology Co.,Ltd is a manufacturer and trader specialized in the research, development and production of PCB depaneling ,Hot bar welding machine and Touch screen film sticking machine. We are located in Dongguan City,Guangdong Province ,China with convenient transportation access. All of our products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

1. who are we?

We are based in Jiangsu, China, start from 2014,sell to Eastern Europe(20.00%),North America(20.00%),South America(15.00%),Southern Europe(10.00%),Northern Europe(10.00%),Western Europe(10.00%),South Asia(10.00%),Mid East(5.00%). There are total about 301-500 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

pcb depaneling,pcb separator,pcb cutting machine,PCB depaneler,v-cut machine

4. why should you buy from us not from other suppliers?

YUSH Electronic Technology Co.,Ltd.Was founded in 2004,is located in the world manufacturing city Jiangsu,Professional pcb separator/pcb depanelizer electronic equipment machinery. The company has advanced production and processing equipment and an experie

5. what services can we provide?

Accepted Delivery Terms: FOB,CIF,EXW,DDP,DDU,Express Delivery,DAF;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,Korean,Hindi

We Recommend

New Arrivals

New products from manufacturers at wholesale prices