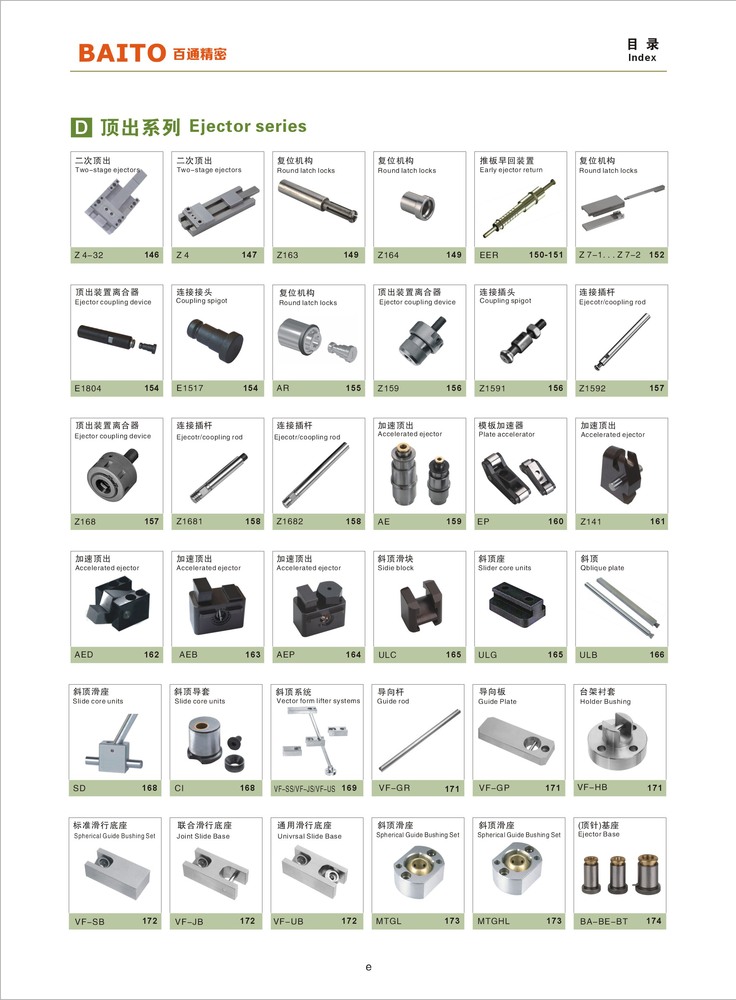

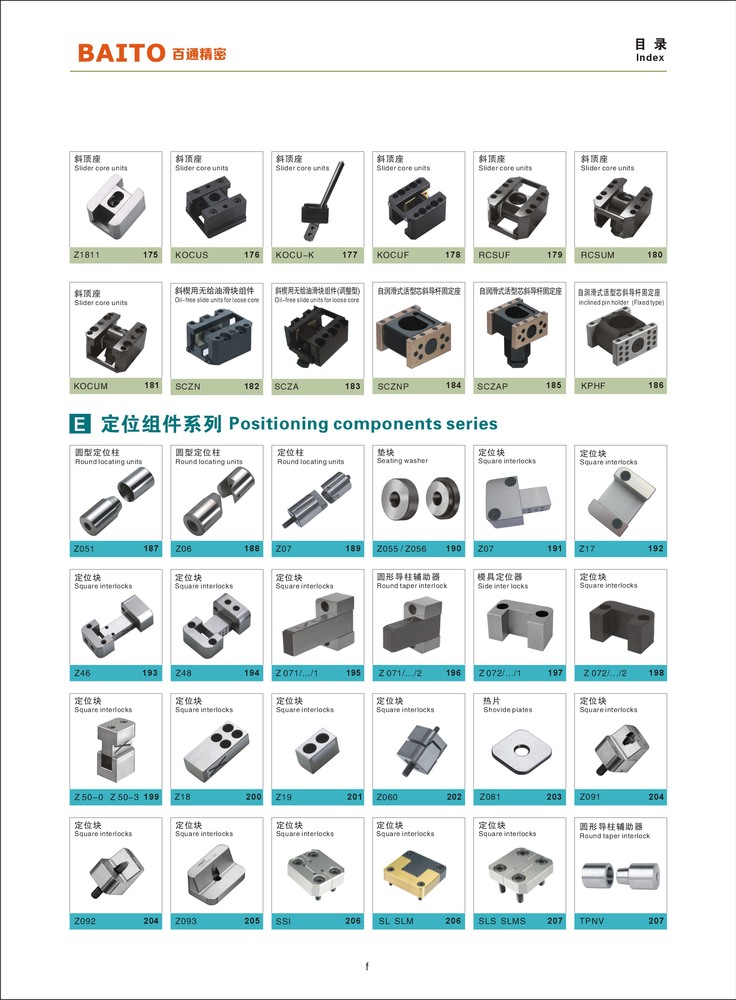

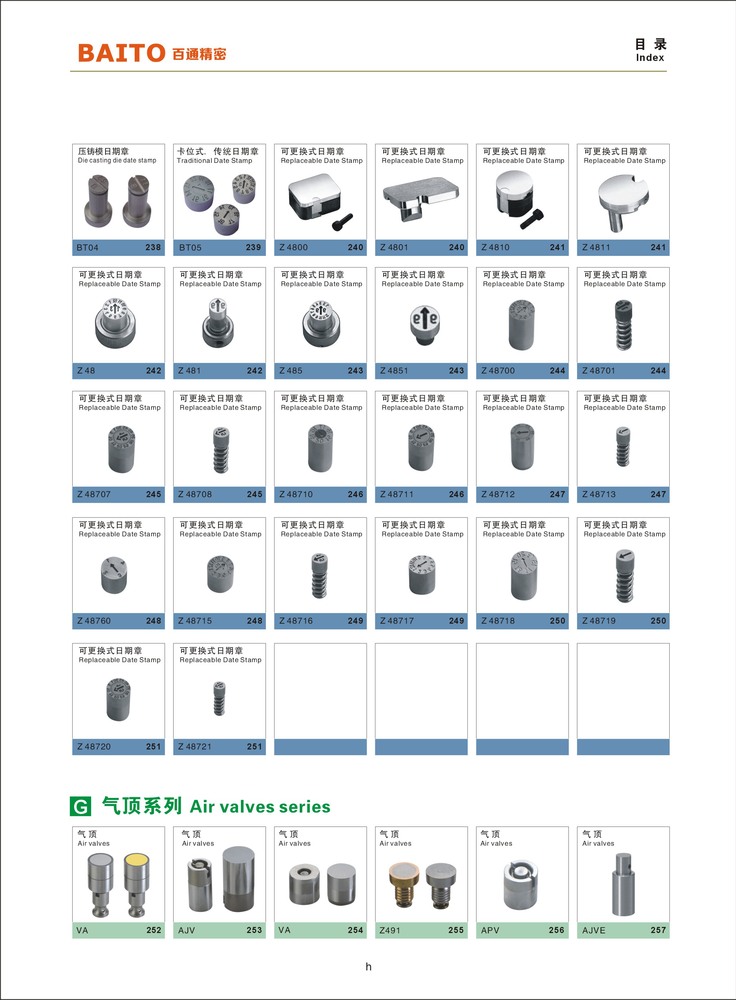

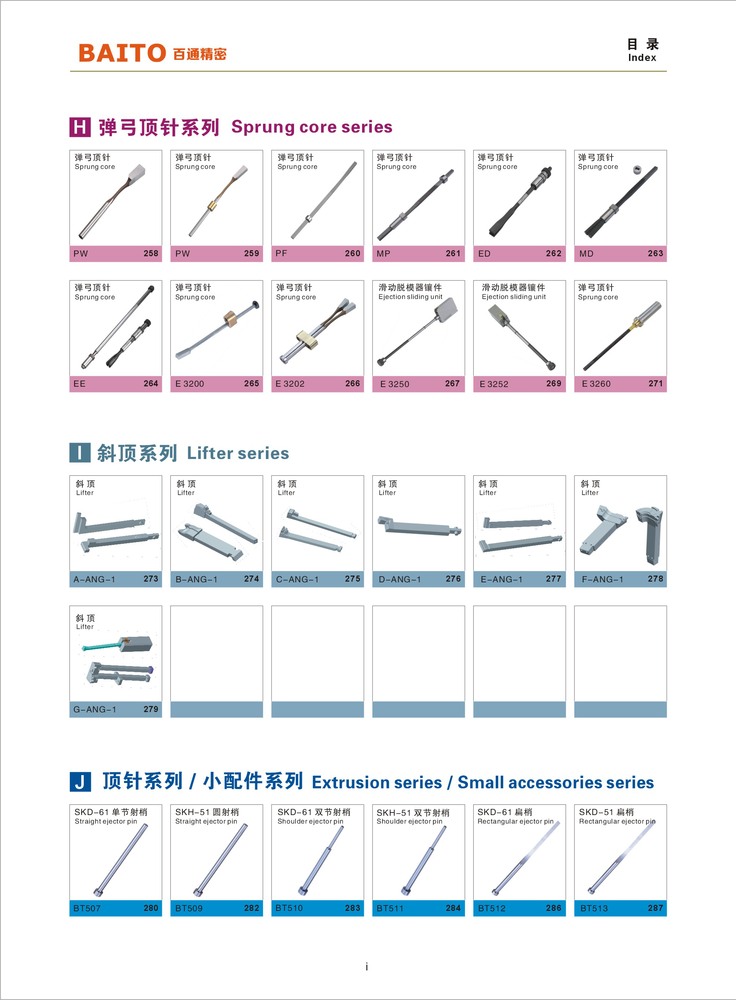

High Quality Customized Made Ejector Pin For Plastic Mold Part metal sleeves DIN1530 Pin Ejector sleeves

- Category: >>>

- Supplier: Dongguan Baitong Precision Mould Manufacturing Co. Ltd.

Share on (1600823895324):

Product Overview

Description

Products Description | |

Machining Equipments | CNC milling machines,Japan Miyano CNC Lath,Japan Go Core machine, surfacegrinding machine,The waters grinding machine,the laser,Centerless grinding,Punch former,Milling machine,Turning machine and so on.

|

Surface Finish | Anodize,polishing,zinc/nickel/chrome/gold plating,sand blasting,Phosphate coating TIN DLC Coating Black coating & etc.

|

Tolerance Precision | +/- 0.002--0.02mm / can also be customized. |

Packaging | Polybag, bubble bags, wooden case. or as requests. |

Shipping | By sea,By air,By DHL,UPS,Fedex,TNT&etc. |

MOQ | 1PCS |

Payment | 100% before shipment. |

Company Advantage |

(1)Competitive factory price with good quality. according your quantity). |

Product Show

Dongguan Baitong Precision Mold Manufacturing Co., Ltd. was founded in Huangjiang Town, Dongguan City in 1998. It is a professional, research and development, production and sales company that supplies mold parts, mold special parts, automatic fixtures, machine tool parts, etc.

Mold accessories are widely used in various plastic molds, stamping molds, automotive, electrical and aviation manufacturing fields. Mold accessories with its high precision requirements, high quality requirements stand in the first hardware accessories. The materials of mold accessories are usually tungsten steel, high-speed steel, bearing steel, stainless steel, brass, metal alloys, spring steel, carbonized steel and so on. It can be said that the products that can be seen everywhere in your daily life are inseparable from the production of mold components

1. Could I have prices of your products? |

Welcome. Pls feel free to send us an email here. You will get our reply in 24 hours |

2. Can we print our logo/website/company name on products? |

Yes, please advise the information of the logo. |

3. What's the lead time for regular order? |

We have stocks about many standard mould components, about 10 workdays for regular order. |

4. Can I get a discount? |

Yes, please contact us to get the best price. |

5. Do you inspect the finished products? |

Yes, each step of production and finished products will be came out inspection by QC department before shipping. |

We Recommend

New Arrivals

New products from manufacturers at wholesale prices