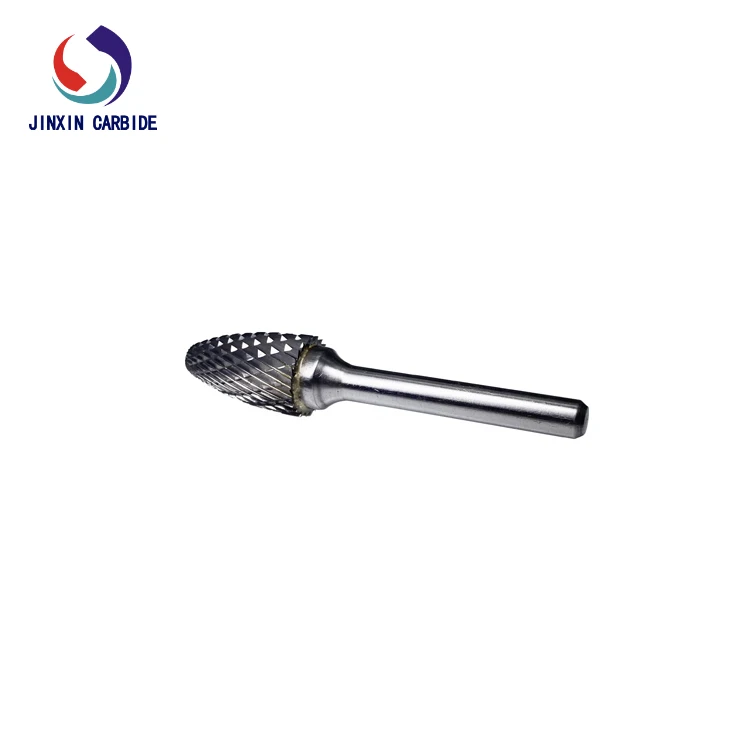

Tree Shape F1020 Tungsten Carbide RotaryCutter Burrs for Metal Grinding

- Category: >>>

- Supplier: Zhuzhou Jinxin Cemented Carbide Group Co. Ltd.

Share on (1600850765710):

Product Overview

Description

Product Description

Product description:

Single-cut burs are for general purpose work and provide good material removal.

Carbide burs/porting tools for metal working. Manufactured on premium automated CNC machines, carbide burs are available in three main styles of cuts – single, double and aluminum.

Single-cut burs are for general purpose work and provide good material removal.

Double-cut burs produce smaller chips for greater operator control on applications such as stainless steels and ferrous materials.

Aluminum-cut burs have a wide flute design for easy stock removal without loading on applications such as nonferrous and soft materials.

Feature:

1. Material: 100% virgin raw material with submicron grain size;

2. Grade: Various grades for choice;

3. Advanced production equipments and testing equipments

4. Precision Ground and polished;

5. High wear resistance,high hardness and impact toughness;

6. Samples & small orders are acceptable.

Application:

Tungsten carbide rotary bur is an effective way to realize merchanization in hand work operations, in the industries of airplane,ship building,automobile, machinery , chemistry, dental, etc. Cemented arbide rotary burrs can be widely used in maching iron,steel casting, carbon steel, alloy steel, stainless steel, copper aluminium , etc.

Feature:

1. Material: 100% virgin raw material with submicron grain size;

2. Grade: Various grades for choice;

3. Advanced production equipments and testing equipments

4. Precision Ground and polished;

5. High wear resistance,high hardness and impact toughness;

6. Samples & small orders are acceptable.

Application:

Tungsten carbide rotary bur is an effective way to realize merchanization in hand work operations, in the industries of airplane,ship building,automobile, machinery , chemistry, dental, etc. Cemented arbide rotary burrs can be widely used in maching iron,steel casting, carbon steel, alloy steel, stainless steel, copper aluminium , etc.

Warm tips:

1.Must wear protection cover when operating and cut 2.Extending cutter should be moderated when operating

3.Adopt different speeds of level according to processing materials

Product Show

Application scenarios

Main Products

1. What are the parameters for the Tungsten carbide burrs?

The shape, cut dia, cut length, tooth type, shank dia, shank length

2. What are the cuts for the tungsten carbide burrs?

Standard cut, Double cut and Aluminium cut.

3.What information should I let you know if i want to get a quotation?

The item number, quantity and application.

4.Do you accept customized?

Yes, we can according to your drawing or sample.

5.Do you inspect the finishing products?

Yes, each product will be inspected by our QC before shipping.

6.What's your shipment term?

DHL, UPS, TNT, FedEx, SF-Express, EMS, 5-8 days will arrived.

7.What is the shipping cost?

It mainly depends on weight, volume, packing size and destination port.

8.What's your delivery time?

In stock, 1-2 days, if not, according to your quantity.

The shape, cut dia, cut length, tooth type, shank dia, shank length

2. What are the cuts for the tungsten carbide burrs?

Standard cut, Double cut and Aluminium cut.

3.What information should I let you know if i want to get a quotation?

The item number, quantity and application.

4.Do you accept customized?

Yes, we can according to your drawing or sample.

5.Do you inspect the finishing products?

Yes, each product will be inspected by our QC before shipping.

6.What's your shipment term?

DHL, UPS, TNT, FedEx, SF-Express, EMS, 5-8 days will arrived.

7.What is the shipping cost?

It mainly depends on weight, volume, packing size and destination port.

8.What's your delivery time?

In stock, 1-2 days, if not, according to your quantity.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices