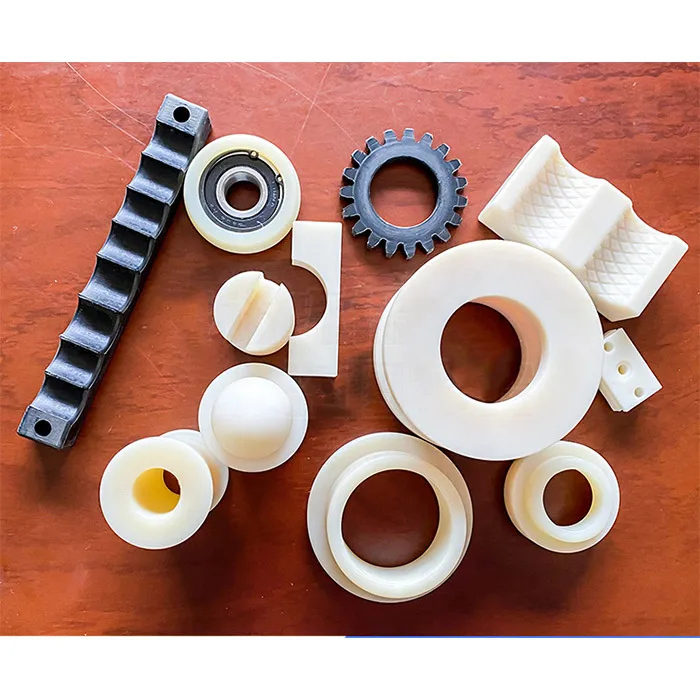

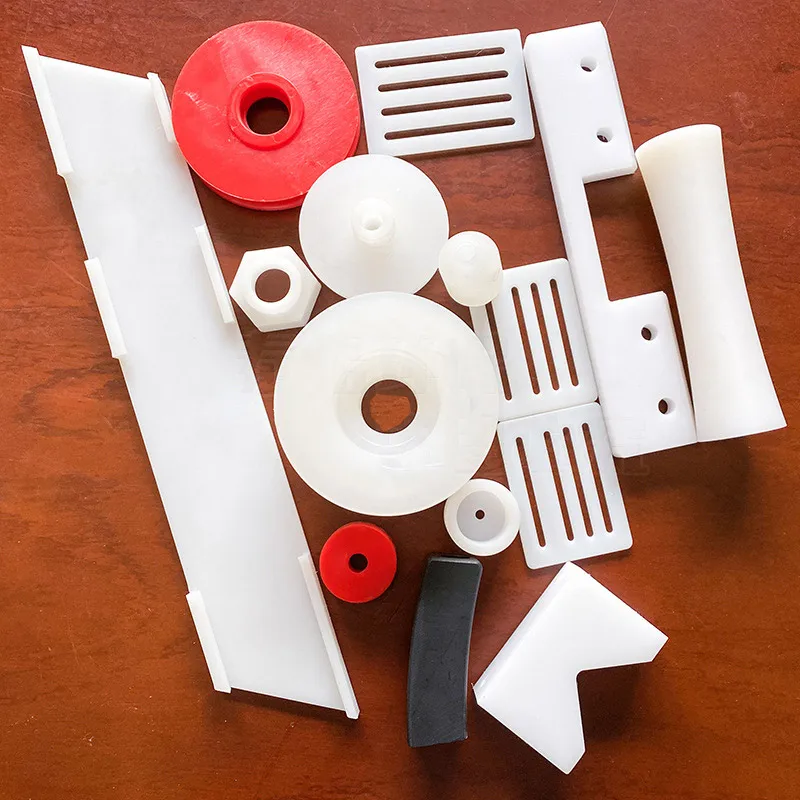

Plastic injection molding processing Multi style models Nylon non standard parts Special shaped parts support mold making

- Category: >>>

- Supplier: KingMetal Precision Industrial Co. LtdKingMetal Ltd

Share on (1600857589156):

Product Overview

Description

Process Details

Specification | ||

Product Name | Cnc Machine Parts Supplier Machining | |

Quotation | According to your drawing(size, material, thickness, processing content and required technology, etc.) | |

Tolerance丨Surface Roughness | +/-0.005 - 0.01mm 丨 Ra0.2 - Ra3.2(Customize available) | |

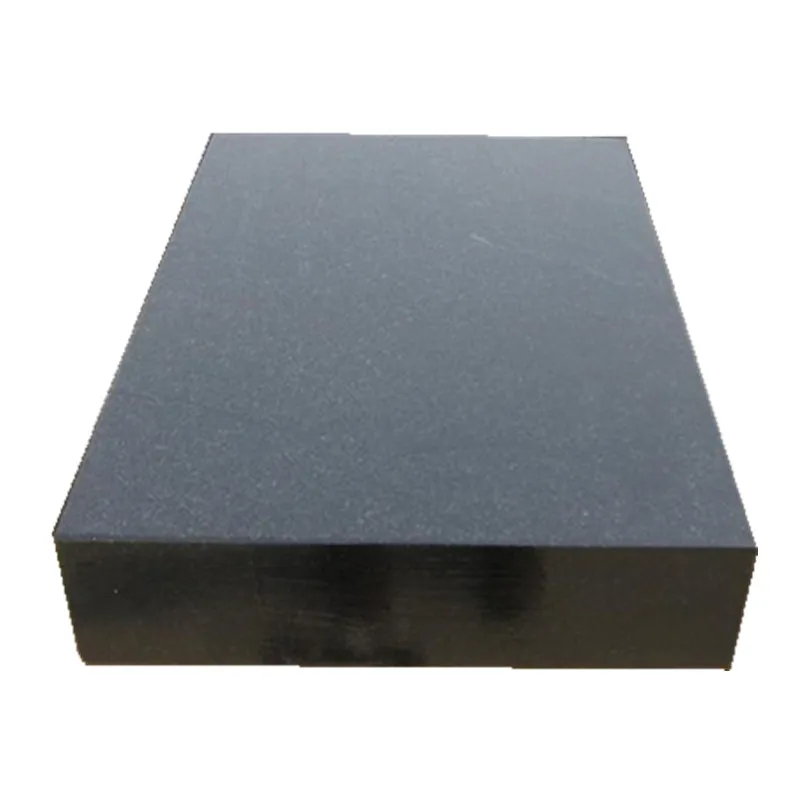

Materials Available | Aluminum ABS, PP, PE, PC, POM SPTE, galvanized sheet copper | |

Processing | Process: CNC machining center | |

Drawing Formats | PRO/E, Auto CAD, Solid Works , UG, CAD / CAM / CAE, PDF | |

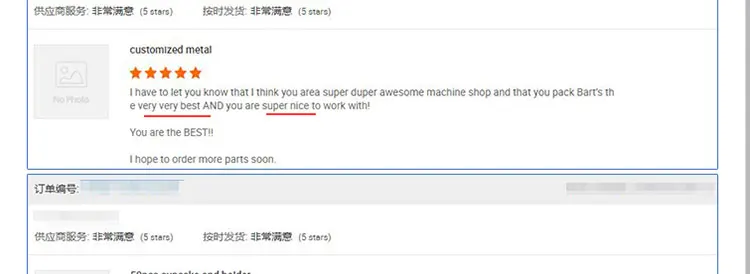

Our Advantages | 1.) 24 Hours Online Service & Quickly Quote / Delivery. 2.) 100% QC quality inspection before delivery, and can provide quality inspection form. 3.) 18+ years of experience in the CNC machining area and have a senior design team to offer perfect modification suggestions. | |

Get a Free Quotation via Us >>> Go | ||

Q: Are you a factory or trading company?

A: KingMetal is a professional manufacturer factory in SHENZHEN of China

Q: How can I get the quotation quickly?

Q: How can I get the quotation quickly?

A: We will submit the quotation in 24 hours if getting detailed information during working days.In order to quote for you earlier, please provide us the following information together with your inquiry.

1) 3D Step of Files and 2D Drawings. 2) Material requirement. 3) Surface treatment.

4) Quantity (per order/per month/annual).

5) Any special demands or requirements, such as packing, labels,delivery,etc.

Q: What are the main oversea markets of KingMetal?

A: Currently KingMetal regular oversea customers are from the US, the UK, Italy, Germany, France and India etc.

Q: How you do the quality control?

A: 1). Materials inspection by IQC;

2). The first sample inspected by QC, QC will do over check as per the parameters list and critical dimensions

requested by customers, to decide if it can go ahead for production;

3). During processing, our IPQC will check the injection molded parts every 2 hours, ensure no any rejects;

4). FQC will check the products before sending to the warehouse;

5). 100% inspected by OQC before shipping out.

Q: What should we do if we receive defective products?

A: If receive defective product,please send us the photos, we will feedback to our engineers and QC departments and

solve the problems ASAP.

Q: How to pack the moulds and products?

A: 1).For moulds, we will be coated one-layer anti-rust oil first,and then also will be covered thin films on the mould, finally

pack into fumigation wooden case.

2).And as to products, we will pack into standard export cartons or as per customer’s request to pack.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices