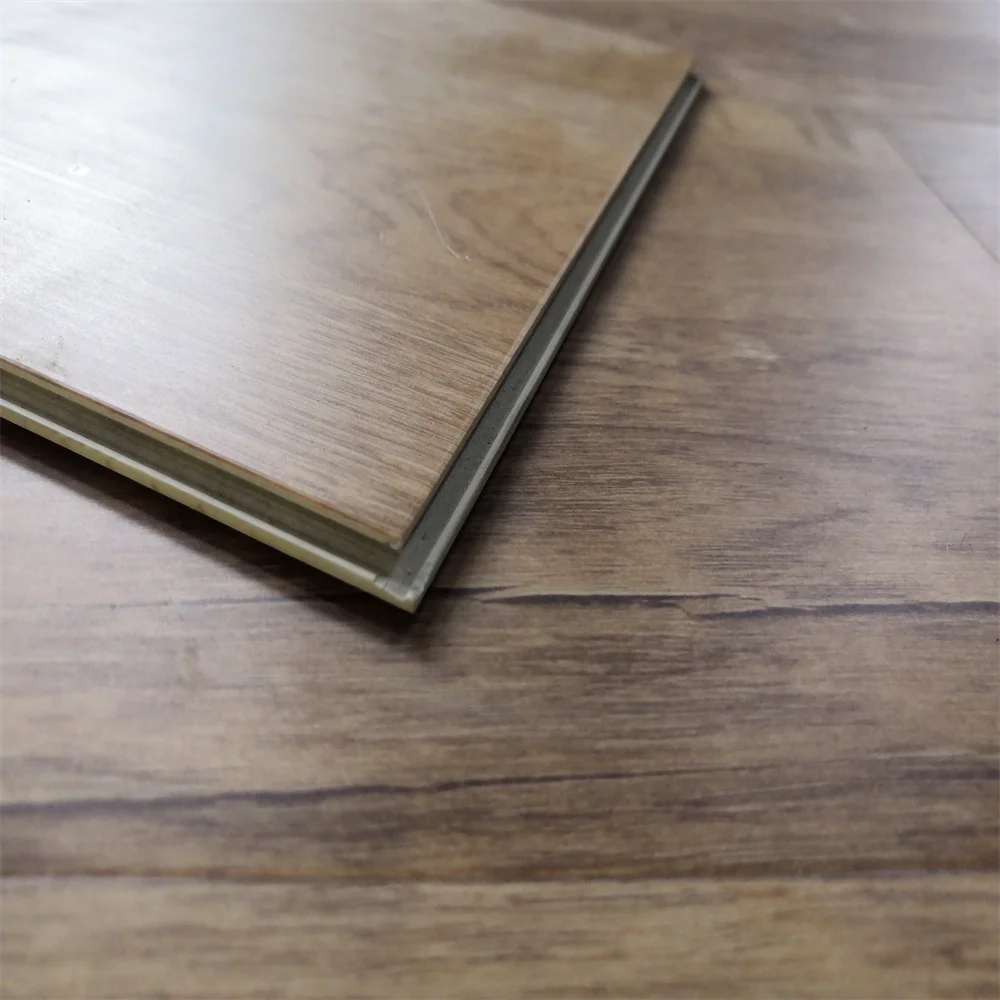

8mm 10mm Waterproof Wooden Laminated Flooring Modern Shiny Solid Laminate wooden Floor Hybrid Flooring

- Category: >>>

- Supplier: Hebei Moyo Technologies Co. Ltd.

Share on (1600867206517):

Product Overview

Description

Laminate flooring is generally composed of four layers of materials, namely wear-resistant layer, decorative layer, high-density substrate layer, and balance (moisture-proof) layer.

Laminated flooring is also called impregnated paper laminated wood flooring and laminated wood flooring. Qualified laminated flooring is impregnated with one or more layers of thermosetting amino resin.

The impregnated paper laminated wooden floor is impregnated with one or more layers of special paper with thermosetting amino resin, paved on the surface of particleboard, high-density fiberboard and other wood-based panels, with a balanced moisture-proof layer on the back, and a wear-resistant layer and decorative layer on the front. Heat-pressed and formed floor.

1. In terms of thickness, there are thin and thick (more than 8 mm and about 12 mm).

From the perspective of environmental protection, thinner is better than thicker. Because it is thin, less glue is used per unit area. Thick ones, the density is not as high as the thin ones, and the impact resistance is almost inferior, but the foot feel is slightly better. In fact, there is not much difference between the two. In fact, there is no difference in the thickness and quality of these two floors. The key is to look at personal choice.

Second, there are standard, wide and narrow boards in terms of specifications

Standard, the width is generally 191-195 mm. The length is around 1200 and 1300. For wide boards, the length is more than 1200 mm and the width is about 295 mm. For narrow boards, the length is 900-1000 mm, and the width is basically about 100 mm. Similar to the specifications of solid wood flooring, most of them are called imitation solid wood flooring tile.

Standard specifications are adopted by most members of the European Flooring Manufacturers Association. It is still the case. Our country imports the world's most advanced, reinforced floor processing assembly line, which also adopts standard specifications. In other words, most of the products of large-scale laminate flooring manufacturers that are processed by imported assembly lines are still standard specifications. There are many dealers in the market who advertise that their products are imported.

A common saying is: "Imported products do not have wide plate specifications and a size of about 12 mm in thickness." It should be the vast majority of imported floors, without wide board specifications and thickened sizes.

The wide-board specification was invented by my country's laminate flooring processing enterprises to meet consumer demand. Its advantages look generous, and there are relatively few gaps in the floor. Most of them are thickened, that is, about 12 mm. Generally, the decorative paper on the surface is domestically produced, with many changes in design and color, which is more flexible. The disadvantage is that the color difference is relatively large, and the anti-ultraviolet ability of the decorative paper is poor.

Narrow plate specifications are also a feature of our country. The solid wood floor looks generous, too expensive, and the stability is not good; the floor manufacturers in my country produce imitation solid wood floor, and its specifications are the same as the solid wood floor, cheap, good stability, and the four sides are made of V-shaped grooves. The thickness is basically around 12mm. It has been in the market for less than a year and is very popular.

3. From the surface coating, there are aluminum oxide, melamine, and piano lacquer.

The surface of the standard laminate floor should all contain aluminum oxide wear-resistant paper. It has 46 grams, 38 grams, 33 grams, and even lower, spraying aluminum oxide directly on the decorative paper. The state stipulates that the surface wear-resistant revolutions of the laminate flooring used indoors should be above 6000 revolutions, and only the floor with 46 grams of wear-resistant paper can meet the requirements. The wear-resistant revolutions of 38 grams of wear-resistant paper can reach 4000-5000 revolutions, and that of 33 grams is lower. For direct spraying of aluminum oxide, it is very good if it can reach 2000-3000 rpm. The lower the number of wear-resistant revolutions, the lower the cost of materials; because of its low degree of wear resistance, the cost of cutting tools during processing is also lower. On the contrary, the higher the number of wear-resistant revolutions, the higher the cost itself.

The melamine surface coating is generally used for wall panels, desktop panels, etc., and is used in places where the degree of wear resistance is not high. This type of surface-coated floor is known in the flooring industry as a "false floor". Its wear-resistant revolutions are only 300-500 revolutions. If it is used intensively, the decorative paper on the surface will wear out after two or three months. Standard laminate flooring will not have this problem for 10 years of normal use. There is no wear-resistant layer on this kind of floor decoration paper, the pattern is beautiful and clear, and it is relatively smooth when touched by hand. This is where laymen are easy to be fooled.

The surface coating of piano lacquer is actually the paint that will be used on the surface of solid wood floors for laminate flooring. It's just a brighter paint. The wear resistance of this coating is far from being comparable to that of the aluminum oxide surface. Its wear resistance is low, and solid wood floors are developing towards high wear resistance. Unless you really like this surface coating.

Fourth, from the characteristics of the floor, there are crystal surface, embossed surface, lock, mute, waterproof and so on.

Crystal surfaces are basically flat. Easy to take care of, easy to tidy up.

Viewed from the front, the embossed surface is no different from the crystal surface. Viewed from the side, if touched by hand, there are wood grain-like patterns on the surface.

Locking, the seams of the floor adopt the locking form, which controls the vertical displacement of the floor and controls the horizontal displacement of the floor; the original tongue and groove type, that is, the often said tongue-and-groove floor, can only control the vertical displacement of the floor . Even the earliest wooden floor boards have no tenons and grooves at the joints, and the displacement in any aspect cannot be controlled, so the floor boards often tilt up, causing people to stumble when walking, which is very inconvenient.

Silent, that is, add cork pads or other pads similar to cork on the back of the floor. After using a cork floor mat, the noise of stepping on the floor can be reduced by more than 20 decibels (quoted from the information of the cork floor mat factory), which has the effects of increasing foot feel, sound absorption, and sound insulation. This plays a positive role in improving the comfort of laminate flooring. It is also a direction for the future development of laminate flooring.

Waterproof, coating the waterproof resin or other waterproof materials on the tongue and groove of the reinforced floor, so that the moisture outside the floor is not easy to invade, and the internal formaldehyde is not easy to release, so that the environmental protection and service life of the floor are obvious. Improvement; especially in the case of large-scale laying, it is inconvenient to leave expansion joints and pressure strips, it can prevent floor arching and reduce floor shrinkage joints.

To sum up, embossed ones are really good-looking; if the wear-resistant paper of the same gram is used, the wear resistance of crystal is relatively higher than that of embossed ones; the quietness of the feet is really good, but it is more expensive; the waterproof ones are very cost-effective , there are not many people who know its function.

Chamfering and rolling paint: a processing technology that cuts off some of the upper edge of the floor, and then paints it to cover the color of the base material, so that the color of the edge is more layered, similar to the solid wood floor, so it is very popular among consumers. After the chamfered and painted boards are paved, there is a very shallow seam on the upper edge between the boards, which is easy to accumulate dust and is inconvenient to clean. There is no such problem with non-chamfered boards.

Molded board: A notable feature of the molded board is that the upper edge of the board has a concave curvature downwards. After the two boards are combined, they are tightly bonded, but there is a small groove, which is called a U-shaped groove in the industry. In most cases, this kind of board is Laminate flooring. A huge advantage of the molded board is that it is easy to clean. The dust in the small grooves is very easy to clean up, just wipe it with a rag or mop.

We produce SPC Uniclick Flooring,LVT Flooring .Meanwhile we also source related product for our trust customers .

Q1: Can you provide free samples?A1:Yes. Free Samples will be prepared within 5 days from confirmation. Freight cost on buyers' shoulder.

A2: After price confirmation, free samples are available to check our quality. The clients need to cover the freight cost. You can pay to our company.

A6: The MOQ is one 20’ container with 4-6 colors from the E- catalog.

If you quantity is less than one container, you can also choose 500sqm per color from our stock color or 1000sqm from the E-catalog.

A7 : Of course. We can printed the package boxes as you required. If you need, we can send the popular designs for your reference.

A10 : CE / ISO9001 / IS014001 etc.

We Recommend

China Manufacturer Wear Resistant MDF Surface AC3 AC4 Plastic Laminate Flooring

New Arrivals

New products from manufacturers at wholesale prices