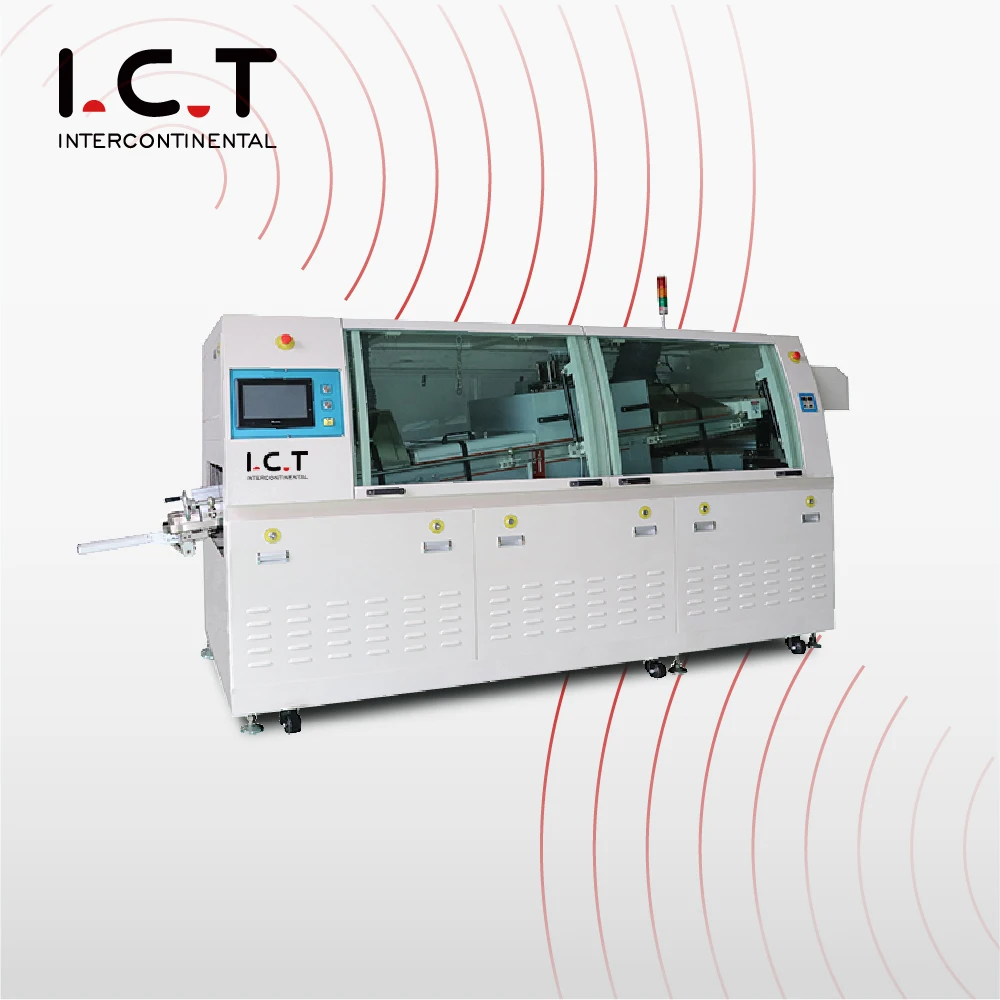

Three Sections Preheating Stages Double Wave Soldering QEW 350 for Automatic SMT Pick and Place Production Line Machine

- Category: >>>

- Supplier: Chipbest Technology (Dongguan) Co. Ltd.

Share on (1600877805907):

Product Overview

Description

Three Sections Preheating Stages Double Wave Soldering QEW-350

for Automatic SMT Pick and Place Production Line Machine

Overall Parameters | |||

Model | QEW-350 | Type of tin furnace | 4th generation adjustable energy-saving tin furnace |

Adjustable width for PCB boards | Max.50~350 | Heating process of tin furnace | Direct-paste matrix three-side heating process, with up to 95% thermal efficiency |

Conveyor height for PCB boards | 750±50mm | Working temperature | Room temperature to 350℃, with control precision of ±1-2℃ |

Optimal soldering speed for PCB | 800-1200mm/Min | Control precision for working temperature | ±10 |

Soldering angle | 3 to 7 degrees | Tin height detection | Conductive probe detection |

Soldering angle display device | Gravity angle display | Tin feeding | Manual |

Height limit for elements | Max.100mm | Temperature control method | P.I.D+SS |

Range of wave height | 0 to 18mm stable | Overall control method | PLC+ Computer |

Number of wave peak | 2 | Flux capacity | / |

Length of preheating zone | 2000MM | Flux adding method | (High configuration) Automatic adding through pneumatic pump |

Number of preheating zone | Four-step preheating zone with one thermal-compensation zone | Flux flow | 5 to 100ml/min |

Thermal compensation | High-frequency traceable spotlight for thermal compensation | Spray mode | Instar stepper motor + A-100 nozzle |

Power of preheating zone | 10KW | Flux recovery | Tray recovery |

Preheating zone temperature | Room temperature to 250℃ adjustable | Power source | Three-phase five-wire system 380V |

Heating method | Hot air | Total initial power | Max.22kw |

Applicable solder type | Lead-free solder / | Normal working power | Approx.3-5kw |

Tin furnace power | 14kw | Air source | 4~7KG/CM2 |

Solder melting capacity of tin furnace | Approx.480kg | Dimensions | 4500*1600*1730 |

Tin furnace material | Cast iron tin furnace | Weight | Approx.1500kg |

Housing Part | |

Body structure | Streamline housing design; adopt industrial channel steel frames and 2mm thickness steel plate for the housing; adopt six universal wheels on the bottom and six cup feet for positioning (for body level and height adjustment); adopt a lengthened arc tempered glass on the front door for maximum viewing angles |

Front door structure | Enclosed transparent tempered glass door with two hydraulic air-spring door brace rods to ensure the largest working and maintenance space |

Rear door structure | Magnet detachable structure with handcuffs for the largest maintenance space |

Top part structure | A set of anti-explosion lighting |

Surface treatment | The overall color is milky (frame of the glass door is azure) |

Spray Party | |

Nozzle | The spray range is 20 to 65mm adjustable sector; nozzle height is 50 to 80mm adjustable; maximum flow 60ml / min |

Air system | Adopting imported filters, control valves and pipe joints; digital air pressure display. Spray air tube uses acid and alkali resistant and corrosion resistant SMC product |

Spray nozzle mobile system | The system is driven by stepper motors and intelligently controlled by a Mitsubishi PLC; it adopts limiting proximity switch and on-board light sensors for composite control; it applies automatic detection of the speed and width of PCB board before spraying. |

Flux recovery system | Apply a stainless steel bending-formation tray under the nozzle to collect waste water and flux; it can be draw out and cleaned at any time |

Flux exhausting and filtering system | Exhausting system: Use stainless steel bracket and double filter screens and recover as much flux as possible by utilizing the fluid characteristics |

Isolating air curtain | Use air pressure knife to blow the excess flux into the recovery box and prevent it from entering the preheating zone. This can ensure production safety. |

Spray box structure | All stainless steel design for convenient cleaning and maintenance. High corrosion resistance and durability |

Preheating Part | |

Four-step preheating zone | 2000mm four-step independent temperature-control preheating zone can provide enough preheating and adjustment space and deal with some larger PCBs or more complicated product; it is compatible with solid-residual or no-washing rosin-type flux; it can reduce the thermal shock of PCBs and realize even heating, to promote the production efficiency. |

Temperature control method | Mitsubishi temperature collecting module and PID temperature controller are precise and reliable; imported thermocouple detection system is capable of thermocouple abnormality warning. |

Heating component | The Taiwan Taizhan heating unit features rapid heating, long service life and small thermal inertia; it can heat the working space evenly. |

Preheating power | Total power 22kw |

Installation mode | The preheating system adopts drawer-type modular design, which is easy to maintain and clean. |

Cover of preheating box | It adopts an arc and streamline design with imported CSR high-density rock wool applied to the inner side to enhance the insulation effect. The front part has an observation window to monitor the whole process. |

We Recommend

New Arrivals

New products from manufacturers at wholesale prices