Endmill Cutting HRC50 4 Flute 4mm 5mm 6mm 8mm 12mm Metal Alloy Carbide Milling Tungsten Steel CNC Machine Tools Router Bits

- Category: >>>

- Supplier: Foshan Yunsheng Metal Technology Co. Ltd.Foshan Ltd.

Share on (1600879303591):

Product Overview

Description

Product Description

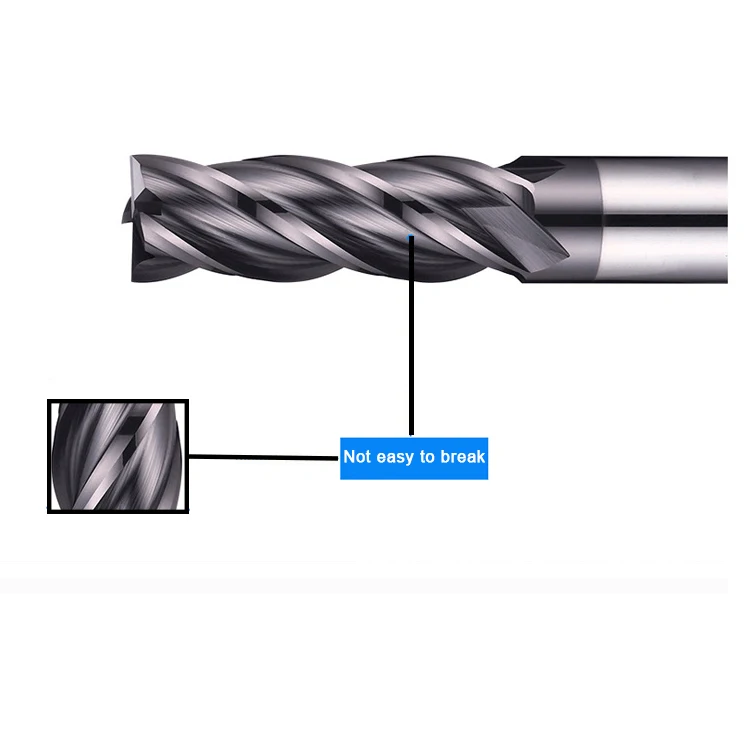

Extended Blade 4 Flute Square End Mill

Description:

◎Hardness: 93 HRA

◎Helix angle: 35°

◎Shank diameter range: S3-20mm

◎Blade length range: C3-60mm

◎Blade diameter range: D1-20mm

◎Full length range: L50-150mm

◎Materials: Imported wear-resistant hard alloy, fine particle tungsten steel

◎Coating: Titanium-containing nanocomposite coating (TiAlN)

◎Applicable processing hardness: HRC30-HRC50

◎Applicable processing materials: copper, iron, castings, steel parts, etc. within HRC30-HRC50°

◎Processing cooling conditions: air cooling, liquid cooling, water cooling

◎Product features: good rigidity, easy chip removal, sharp non-stick knife, high gloss, high machining accuracy, suitable for forming milling, U milling,

◎Shaft form: round handle

◎Applicable machine tools: CNC machining centers, engraving machines, etc.

◎Helix angle: 35°

◎Shank diameter range: S3-20mm

◎Blade length range: C3-60mm

◎Blade diameter range: D1-20mm

◎Full length range: L50-150mm

◎Materials: Imported wear-resistant hard alloy, fine particle tungsten steel

◎Coating: Titanium-containing nanocomposite coating (TiAlN)

◎Applicable processing hardness: HRC30-HRC50

◎Applicable processing materials: copper, iron, castings, steel parts, etc. within HRC30-HRC50°

◎Processing cooling conditions: air cooling, liquid cooling, water cooling

◎Product features: good rigidity, easy chip removal, sharp non-stick knife, high gloss, high machining accuracy, suitable for forming milling, U milling,

◎Shaft form: round handle

◎Applicable machine tools: CNC machining centers, engraving machines, etc.

Features:

1. Non stick knife, tasteless, quiet, blade design, sharp

1. Non stick knife, tasteless, quiet, blade design, sharp

2. Clean, tidy, no burr

3. Spiral chip design, chip smooth, reduce heat

4. Suitable for milling Die steel, Aluminum Alloy, Copper, Cast iron, e

4. Suitable for milling Die steel, Aluminum Alloy, Copper, Cast iron, e

Notes:

Finishing End Mills are used in metalworking applications for removing material or burrs from a workpiece and leaving behind a smooth finish. 4 Flute Finishing End Mills are used for center cutting (plunge cut) operation and when chip removal in slots & grooves is a problem. A wide range of coatings such as Titanium Nitride (TiN), Titanium Carbon Nitride (TiCN), Titanium Aluminum Nitride (TiAlN or AlTiN), and Diamond finishes permit maximum performance and value for a particular application or material. Both standard and metric shank and cutting diameters are available.

Specification

item | value |

Warranty | Other |

Drill Type | Extended Blade Square End Mill |

Surface Finish | TiAlN |

Customized support | OEM, ODM |

Product name | 4 Flute End Mill |

MOQ | 10 Pieces |

OEM | Warmly Welcomed |

Flute | 4flutes |

Helix Angle | 35° |

Hardness | 93 HRA |

Handle Diameter | S4-20mm |

Blade Length | C4-70mm |

Blade Diameter | D1-20mm |

Overall Length | L50-100mm |

Customer Service

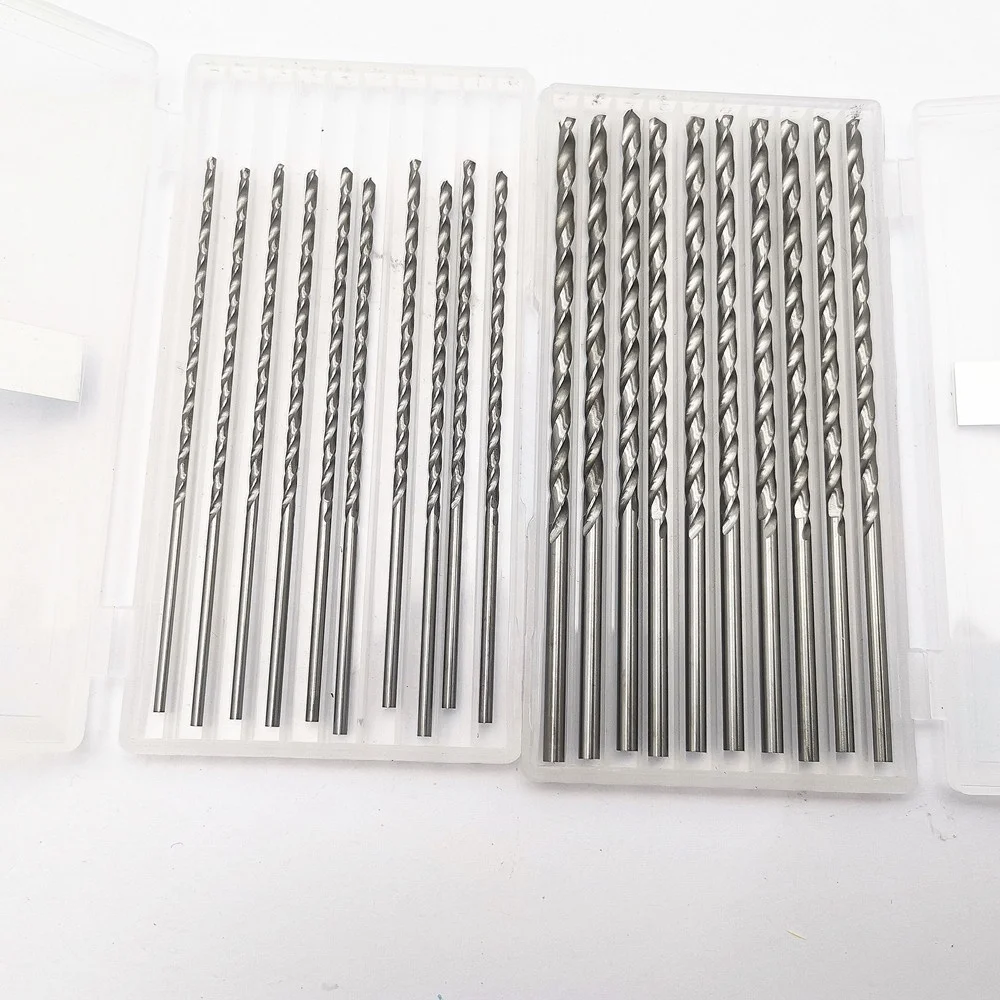

Product packaging

1. Put the gun drill in a plastic box specially for end mill

2. Add cushioning padding in the plastic box

3. Wrap the sponge or other cushioning material in the plastic box with the end mill

4. Packed in carton or wooden box for shipping

2. Add cushioning padding in the plastic box

3. Wrap the sponge or other cushioning material in the plastic box with the end mill

4. Packed in carton or wooden box for shipping

Company Profile

Yunsheng Metal Technology Co., Ltd. is an enterprise specializing in deep hole tool manufacturing and large and complex deep hole machining. Since 2006, we have established a firm foothold in the domestic market, and have won many customers in Southeast Asia, the United States and other places. The company has also introduced foreign advanced technology and equipment to create a scientific research team that pursues excellence and continuous innovation, dedicated to Research and development, production and actual programming solutions for tool use in deep hole machining to improve the machining efficiency and service life of the tool.

We also import raw materials such as tungsten carbide tips and rods from Germany, which are mainly used for brazing single edge gun drills, brazing double edge gun drills, solid carbide gun drills, convertible (clamp) gun drills, inner row deep hole drills. Special tools for deep hole machining and accessories for deep hole machining can widely meet the needs of different customers.

We also import raw materials such as tungsten carbide tips and rods from Germany, which are mainly used for brazing single edge gun drills, brazing double edge gun drills, solid carbide gun drills, convertible (clamp) gun drills, inner row deep hole drills. Special tools for deep hole machining and accessories for deep hole machining can widely meet the needs of different customers.

Due to the complexity of large-scale deep hole machining, we are also equipped with a strong after-sales service team to provide one-stop service for deep hole tool machining solutions. We pursue the goal of excellence and hope to maintain close cooperation with machining centers all over the world.

Why Choose Us

FAQ

Q1: Are you trading company or manufacturer ?

A1: We are a company integrating industry and trade. The office is near the factory, so we can monitor the production of the factory. At the same time, we are also equipped with a strong after-sales service team to provide one-stop service for deep hole tool processing solutions.

Q2: How long is your delivery time?

A2: Generally it is 10-15 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q3: Do you provide samples ?

A3: Yes, we provide sample service, communicate with us about sample clearance to provide you with the best solution

Q4:Can you make the products as our requirement?

A4:We have more than 10 years' OEM experience. We supply products fo more than 100 parts factories.

Q5: What is your terms of payment ?

A5: Payment will be made by T/T and so on.Please contact us

A1: We are a company integrating industry and trade. The office is near the factory, so we can monitor the production of the factory. At the same time, we are also equipped with a strong after-sales service team to provide one-stop service for deep hole tool processing solutions.

Q2: How long is your delivery time?

A2: Generally it is 10-15 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q3: Do you provide samples ?

A3: Yes, we provide sample service, communicate with us about sample clearance to provide you with the best solution

Q4:Can you make the products as our requirement?

A4:We have more than 10 years' OEM experience. We supply products fo more than 100 parts factories.

Q5: What is your terms of payment ?

A5: Payment will be made by T/T and so on.Please contact us

Recommend Products

We Recommend

New Arrivals

New products from manufacturers at wholesale prices