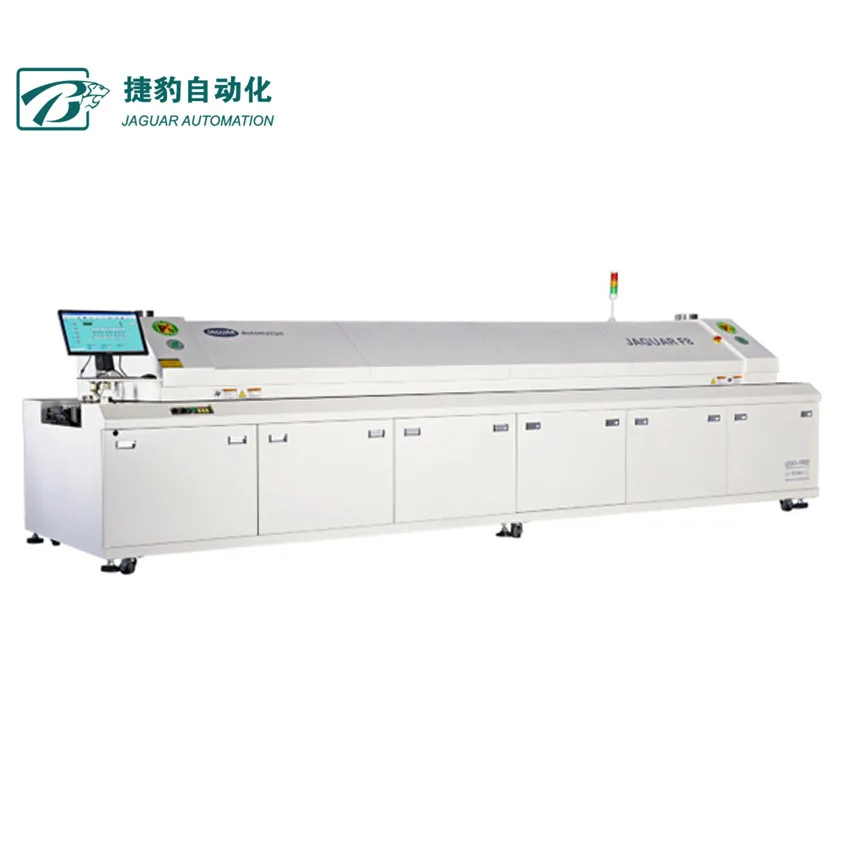

SMT solder reflow oven machine, welding machine

- Category: >>>

- Supplier: Chipbest Technology (Dongguan) Co. Ltd.

Share on (1600880570967):

Product Overview

Description

CSMT solder reflow oven machine, welding machine

UMR-82A reflow oven Specification:

Machine Specification | ||||

Model | UMR-82A | Control | Industrial computer | |

Heating zones qty. | Top 8, bottom 8 | Cooling zones qty. | Top 3, bottom 3 | |

Heating zone length | 3115mm | Rectifying plate | Thick copper plate | |

Weight | Approx:2710kg | Dimension | 5525*1433*1535mm | |

Exhaust capacity | 11SM/min×2 | Color | Grey | |

Control system | ||||

Electricity supply | 3P 380V/220V 50/60HZ | Temp. control range | Room temp.~300℃ | |

Total power | 64KW | Temp. control accuracy | ±1℃(static state) | |

Start power | 30KW | Temp. control method | Closed loop, PID +SSR | |

Consumption power | 9KW | PCB temperature deviation | ±1.5℃ | |

Speed control | 3 Inverters adjust | Data save | All profiles can be saved | |

Warm up time | Apprx.30minute | Abnormal alarm | High, low temp. alarm | |

Conveying system | ||||

Rail structure | 2 segments rails | Rail fixed method | Front fix | |

Chain structure | Stainless steel, stuck-free type | Conveying height | 900±20mm | |

PCB Max. width | 50-460mm | Conveying method | Chain+ mesh+ rail | |

Component height | Top/bottom 30mm | Conveying speed | 300-2000mm | |

Conveying direction | Left to right | Lubrication | Automatic from sw | |

Width adjust | Automatic by recipe | Conveyor motor | Panasonic | |

Max. temp. difference between preheat zone and soldering zone: 90 ℃ | ||||

Max. temp. difference between preheat zone: 50 ℃ | ||||

Max. temp. difference between solder zone: 50 ℃ | ||||

Cooling system | ||||

Cooling method | Forced air cooling | |||

Cooling zone | 3 cooling zones, length is 1140mm, cool down the PCB quickly and reduce the heat impact when the PCB exit from the oven. | |||

Cooling flux manage | With separate flux management in the cooling zone, make it clean all the time, easy for maintenance. | |||

Heating features | ||||

Heating zones | Top 8,bottom 8(3110mm)can meet the need of the peak lead-free technique. | |||

Exit temperature | After cool down by forced air, PCB temp. is ≤70℃ at the exit. | |||

Warm up time | From the normal temp. to set temp, approximate 30 minutes. | |||

Warm up sequence | Warm up from two side, save the power and time | |||

Profile transfer time | <15min | |||

Heating zone temp. control accuracy | ±1℃ | |||

PCB temp. deviation | ±1℃ | |||

Empty to full load heat balance respond time | ≤20 s | |||

Heating zones separately close function | Every heating zone can be closed separately on computer. When the bottom heating zones are closed, the PCB two sides temp. different reaches max.(PCB of different material, thickness, size, the temp. difference value is different.) | |||

We Recommend

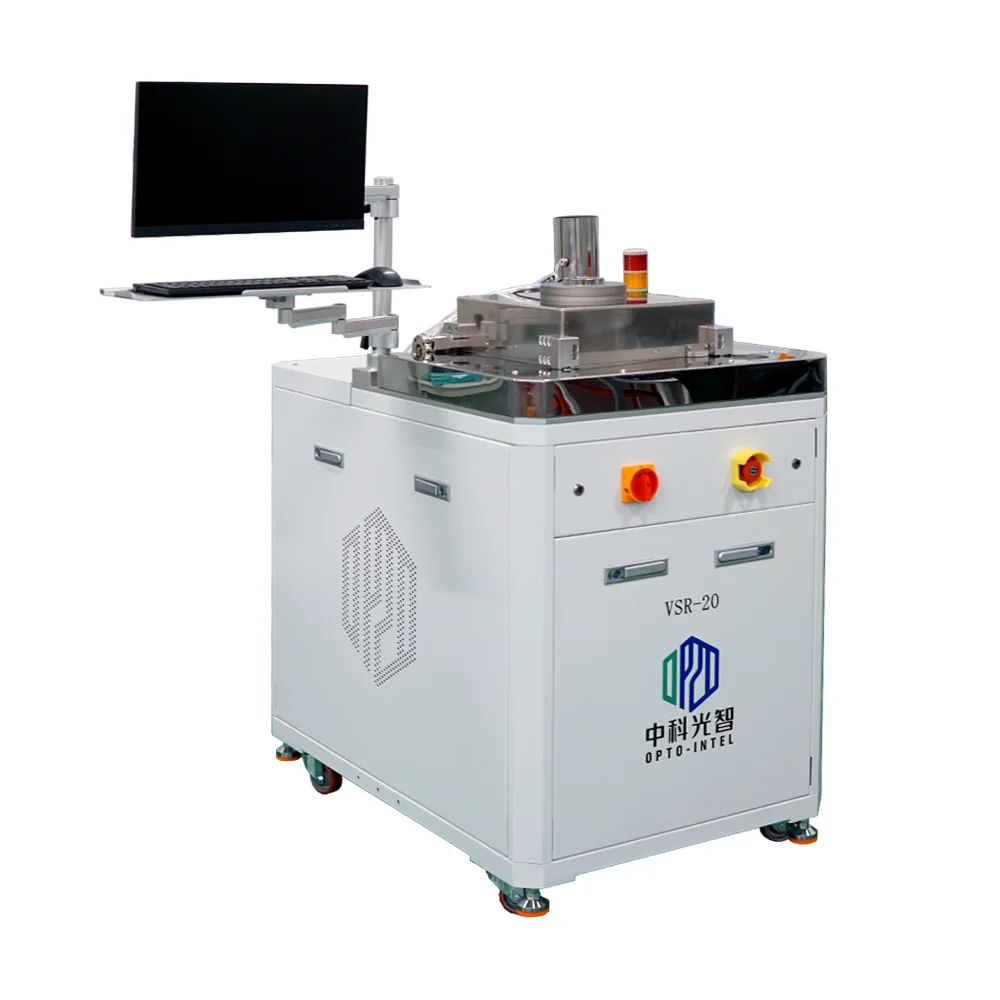

Power Module Device Vacuum Reflow Oven KD-V10N China Factory Vacuum Soldering Oven

Hanwha SM482 Plus Pick and Place Machine

Vacuum Soldering Furnace Formic Acid Vacuum Soldering System IGBT Module Packaging Oven

New Arrivals

New products from manufacturers at wholesale prices