good quality reliable structure mobile diesel engine hammer crusher

- Category: >>>

- Supplier: Henan Kolev Equipment Technology Co. Ltd

Share on (1600890286851):

Product Overview

Description

Product Overview

About hammer crusher you don't know

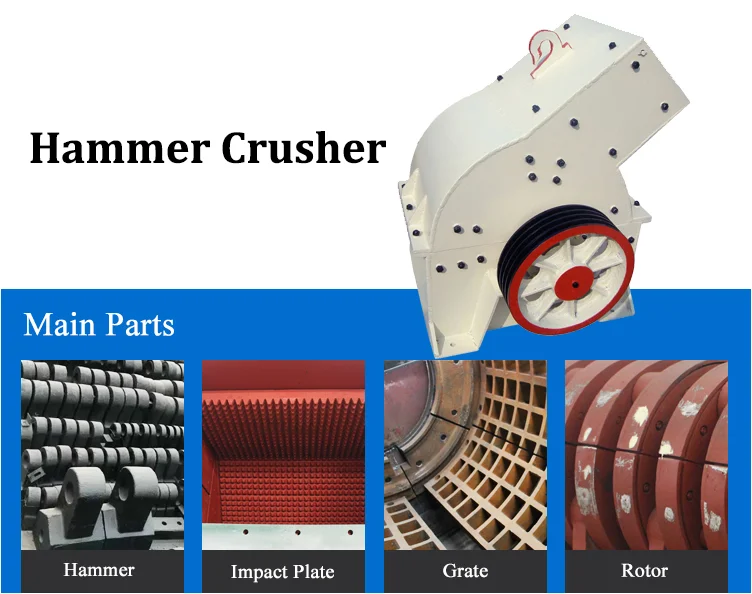

Hammer crusher components:

Casing, rotor, main shaft, hammer head, lining plate and striking plate

The hammer head is made of innovative high wear-resistant materials and high-quality alloy steel, with high hardness, non-fracture, wear resistance, impact resistance and long replacement cycle.The discharge particle size can be easily adjusted as required.

All our hammer crusher can be customized with mobile or diesel

whatsapp:+8613283852702 EMAIL:Henankelefu003@163.com

The hammer crusher body structure adopts sealed design, which avoids a large amount of dust pollution during operation, and is a representative product of environment-friendly crusher.

Hammer crusher is suitable for crushing medium-hard and brittle materials, such as bluestone, river pebble, limestone, slag, coke,construction waste, coal gangue, waste glass and other materials. The discharge particle shape is good, and size can be adjusted freely to meet production requirements.Hammer crusher is divided into single rotor and double rotor, which can directly crush materials with the maximum particle size of 600-1800mm to 25 or less than 25mm.

Techinical Parameter

Model | Feed size(mm) | Discharge size(mm) | Capacity (t/h) | Speed (r/m) | Motor Power(kw) | Weight (t) | Dimension (L*W*H)(mm) |

PCΦ400*300 | ≤200 | ≤25 | 5-10 | 1500 | 11 | 0.8 | 900*670*860 |

PCΦ600*400 | ≤250 | ≤30 | 10-22 | 1500 | 22 | 1.5 | 1200*1050*1200 |

PCΦ800*600 | ≤250 | ≤25 | 18-40 | 1500 | 55 | 3.8 | 1310*1180*1310 |

PCΦ1000*800 | ≤350 | ≤35 | 25-50 | 1500 | 75 | 4.9 | 1600*1390*1575 |

PCΦ1000*1000 | ≤300 | ≤35 | 30-55 | 1000 | 132 | 8 | 1800*1590*1775 |

PCΦ1250*1250 | ≤350 | ≤35 | 35-65 | 1000 | 180 | 14 | 2060*1600*1890 |

PCΦ1400*1400 | ≤350 | ≤35 | 50-100 | 1000 | 280 | 32 | 2365*1870*2220 |

PCΦ1600*1600 | ≤350 | ≤35 | 100-150 | 750 | 480 | 37.5 | 3050*2850*2800 |

Working principle of hammer crusher

When the hammer crusher or hammer crushing machine works, the motor drives the rotor to spin at high speed, materials are fed into the crushing cavity evenly, and then be impacted, cut and tore by high speed spinning hammer head till they are completely crushed. Meanwhile, the gravity action of materials forces them to crash the baffle and grate bars on the frame. Materials with particle size smaller than the screen size will pass the sieve plate while those with bigger particle size are stopped on the plate and will continue to be impacted and grounded by the hammer until they are crushed to the required particle size, finally, crushed materials will be discharged from the hammer crusher through the sieve plate.

Features of hammer crusher

1. The hammer head adopts the new casting process, which has the advantages of wear resistance and impact resistance.

2. Large feed particle size, high yield, good grain shape.

3. The granularity can be adjusted according to customer requirements.

4. The body has sealing structure, which solves the ash leakage and dust pollution problems of crushing workshop.

5. Beautiful appearance, compact structure, less wearing parts, convenient maintenance,good wear resistance.

2. Large feed particle size, high yield, good grain shape.

3. The granularity can be adjusted according to customer requirements.

4. The body has sealing structure, which solves the ash leakage and dust pollution problems of crushing workshop.

5. Beautiful appearance, compact structure, less wearing parts, convenient maintenance,good wear resistance.

Packing and Delivery

FAQ

Q1: Are you factory or trading company?

A1: we are factory, Self-produced and self-sold.

Q2: How about the quality of your products?

A2: No one pays more attention to product quality than we do,our boss is technical background, he is not a businessman, he often says that manufacturing inferior product is equal to producing garbage,This slogan has been hung in our production workshop.

Q3:Do you provide complete solutions?

A3: Yes,we provide kinds of solutions in drying, milling, crushing and sand making area! And we are professional!

A3: Yes,we provide kinds of solutions in drying, milling, crushing and sand making area! And we are professional!

Q4:How is your company's financial situation

A4:The company's operation is excellent without any debts and loans, and the plant and land have property rights

Q5:Do your company has any certification

A5:At present, we have 26 utility model patents and many invention patents

Q6:How about the after-sale service?

A6:12 months warranty for all kinds of products.

Q7: How to get the free solution and quotation ?

A7: Please send inquiry to us ,leave your whatsapp and email , our sales manager will contact you as soon as possible

We Recommend

New Arrivals

New products from manufacturers at wholesale prices