QT4 15 Full Automatic Hollow Concrete Interlock Cement Block Machine Brick Making Machinery Online Jobs Work From Home

- Category: >>>

- Supplier: Linyi Dongyue Imp. & Exp. Co. Ltd.Linyi Ltd.

Share on (1600894967487):

Product Overview

Description

Product Application.

QT4-15 s type permeable brick machine is one of the dongyue machinery co., LTD., brick machine equipment, the equipment structure is simple and practical, outlook is novel and attractive, in addition to produce permeable brick, it is particularly suited to the production of standard bricks, replacement of mold can produce many kinds of paving brick, hollow brick, curb stone etc.

The water-permeable brick machine adopts hydraulic transmission, the operation is smooth and reliable, the hydraulic pressure is combined with the high efficiency vibration forming, the block thickness and the quality is good.

peasonable raw material ratio can produce high strength standard brick, after forming, can stack immediately.

Main technical parameter | ||||||

Dimension of host machine | 3700x2100x2300MM | |||||

Mould perod | 15-25S | |||||

Vibration force | 35.5KN | |||||

Pallet size | 850x550x25MM | |||||

Mixer model | JQ500 | |||||

Workshop area | 160M2 | |||||

Weight | 3500KGS | |||||

Voltage | 380/415/440V | |||||

Production Capacity | ||||||

Size(LxWxH) | Pcs/Mould | Pcs/Hour | Pcs/Shift | |||

400x200x200MM | 4 | 576 | 4608 | |||

400x150x200MM | 5 | 720 | 5760 | |||

400x100x200MM | 7 | 1008 | 8064 | |||

200x100x60MM | 14 | 2520 | 20160 | |||

245x130x60MM | 12 | 2160 | 17280 | |||

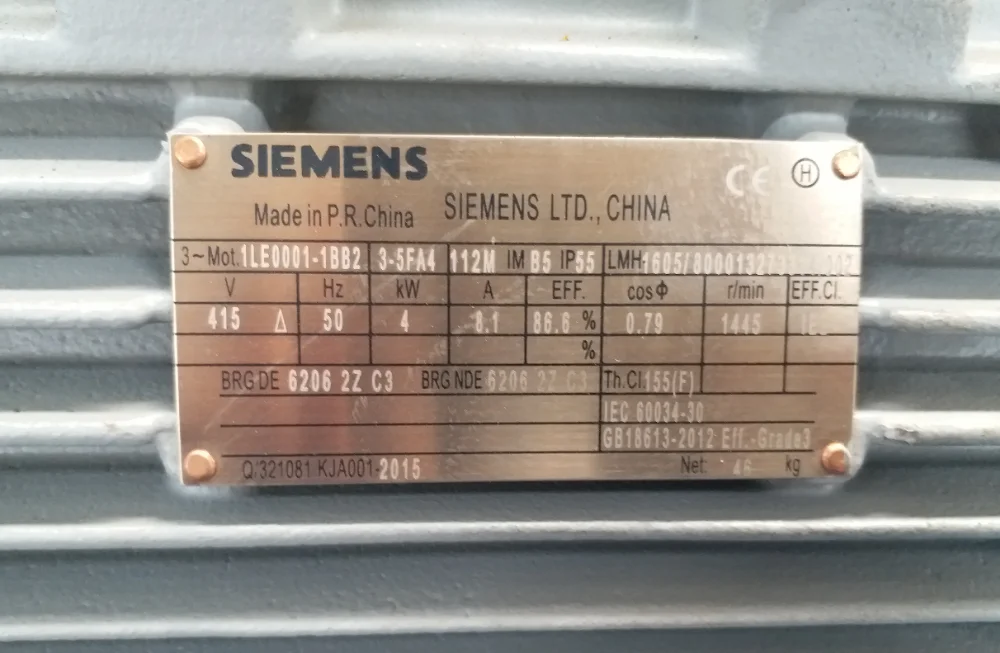

Siemens brand motor

Brand: Siemens

Original: Germany

Famous brand motor ,can do warranty in abroad .

longer service life .

Japan Mitsubishi brand PLC

Name:PLC

Brand: Mitsubishi brandOriginal: Japan

Famous brand PLC unit , running smoothly ,and no error.

France Schneider brand AC Contactor

Name : AC Contactor

Brand : Schneider brand

Origin : France

High quality ,famous bran , no broken

Synchronizing gear .

Machine two side add the synchronizing gear ,to ensure the movement all the same time and same position ,reduce problem occurs

2) Control PLC: we select original Japan Mitsubishi PLCcombine with independently develop machine control program, assure stable and high efficiency working status

3) The switch will use France Schneider brand and Japan Omron

4) Mould: newest heat treatment device and carburizing treatment will assure longer mould life span and ensure the strength of mould reach to 54-58 HRC so that the mould can be used more than 100 thousand times.

5)Material and welding: all materials and spare parts selected according to international CE standard, Carbon dioxide protection welding will assure whole line stable running.

Can also be upgraded to a mixer with lifting hopper

stability of machine operation

We provide complete technical support, including site planning, installation guidance, technical training and after-sales service.

1.Material and welding: All material and spare parts selected according to international CE standard, Carbon dioxide protection will assure whole line stable running.

2. Electric control system: We selected original Mitsubishi PLC combine with independent machine control system to assure stable and high-efficiency working status.

3.Switches and motor:Switched will use Japan Omron or France Schneider, motor will use Siemens or ABB band.

4.Hydraulic system: The machine adopting the advanced hydraulic molding technology, it can assure the block machine have stable and high-efficiency working status, and the blocks produced are of better quality,larger density and higher strength.

5.Block mould: Our block moulds are made of Q355R manganese steel.Besides the good raw material, precise line cutting technology and 900ºC carburizing heat treatment technology are all adopted in the process of brick moulds production.Then the mould size error can be controlled within 0.002mm . The surface layer of the brick moulds get higher hardness (achieving HRC54-58) and better wear resistance.

6. Vibration system: The machine adopts the special technology to optimize the vibration shaft, so that the proportion of vibration is covered in the whole surface range, so the product quality is greatly improved and the noise is effectively reduced. The machine's unique fixed

platform design forms can improve the molding speed and dimensional accuracy.

2. 8-10% cement, 30% fly ash, 60% sand or stone powder

Other materials can also be used

2.Mixing Section: After being mixed evenly with water, raw material are unloaded to the block making machine through belt conveyor.

3.Block forming Section: Mixed raw material are then sent to the mould case. Under PLC computer intelligent control. Hydraulic transmission, vibration, shaping takes place.

4.Automatic Stacker Section: After demoulding ,green brick will be unloaded to the bamboo pallet.

5.Block Curing Section : Wet product will be conveyed through green block conveyor then to the stacker.

Pre-Sales Service.

* Inquiry and consulting support.

* machine test performance

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery oversea

Moblie: +86 13562941171( Whatsapp, Wechat)

Web: //www.chinablockmachine.com

//www.dyjxjt.com

//www.dongyuegroup.com

Website on alibaba.com: sddymachine.en.alibaba.com

Facebook: https://www.facebook.com/profile.php?id=100084546947507

Instagram: https://www.instagram.com/mary_donyuemachine/

Youtube: https://www.youtube.com/channel/UCbRDJu3jHf9UIlbN1yXFmeQ

We Recommend

New Arrivals

New products from manufacturers at wholesale prices