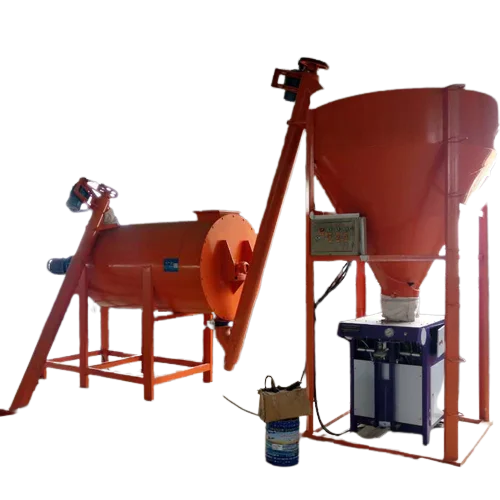

Dry Mortar Mixing Machine Latest Technology Earning Ceramic Tile Adhesive Mortar Plant Low Investment Money

- Category: >>>

- Supplier: Zhengzhou Mg Industrial Co. Ltd.

Share on (1600895111343):

Product Overview

Description

Product Description

This production line adopted latest Germany Technology,the silo is in tower type,and latest management system applied in automatic control,improved the man-friendly operation and automatic in large extent.The capacity of this automatic dry mortar production line at 3-30

ton per hour.

.

The advantages of our Automatic dry mortar mixing equipment.

1, A high degree of intelligence. It is controlled by the control system and realizes automatic automation of automatic batching, automatic weighing, automatic feeding, automatic mixing and automatic packaging.

2, The ingredients are accurate, can automatically calculate the error and automatically correct.

3, The use of tower layout structure, shorten the transmission distance and increase production efficiency.

4. The use of a biaxial mixer( Twin shaft mixer) has high mixing uniformity, and materials with large differences in physical properties such as specific gravity, particle size and shape do not easily segregate when mixed in the mixer.

| Model | 2000L Mixer | 3000/4000L Mixer | 6000L Mixer Plant | 10000L Mixer plant |

| Capacity | 10-12T/H | 15-30T/H | 30-50T/H | 60-70T/H |

| Machine height | 8-10m | 10-14m | 15-20m | 20-25m |

| Total power | 80-90KW | 90-100KW | 100-120KW | 120-150KW |

| Worker required | 2-3 person | 3-4 person | 3-4 person | 3-4 person |

| Workshop required | 500-600m2 | 600-800m2 | 800-1000m2 | 1000-1500m2 |

| Bag belt conveyor | B500X5000mm | B500X5000mm | B500X5000mm | B500X5000mm |

| Pallet wrapping machine | Provide | Provide | Provide | Provide |

| Sand dryer | As requirement | As requirement | As requirement | As requirement |

Main configuration

Three Cyliner Rotary Sand Dryer

High efficiency ,energy saving and less space occupied

The widely used rotary sand dryer is made up of three different diameter homocentric cylinder according to the certain mathematical relationship and cylinder structure then combinated by embedded with each another.Because of the three-cylinder dryer special structure, the length of the cylinder body is the single cylinder dryer one third.Base area than the single cylinder dryer save 65%, the basic investment corresponding reduced.

Linear Vibrating Screen

Low noise,energy saving,high screening accuracy

Linear vibrating screen adopts the vibration motor excitation principle to make the material thrown up on the screen surface and make jump movement towards the outlet of the screen.After the material is graded by the vibrating screen,it is discharged from different outlets according to the particle size,so as to complete the classification of material.

Raw Material Detachable Storage Silo

Customized volume 150T, 100T, 60T, Easy transportation, waterproof manufacturing

The silo is used to store dry building raw material powder, such as sand, cement, fly ash, slag, calcium carbonate powder and so on. MG standard silos will equips level regulars, air breaking device, e-dust collector, pressure safety valve and complete set of assemble accessories.

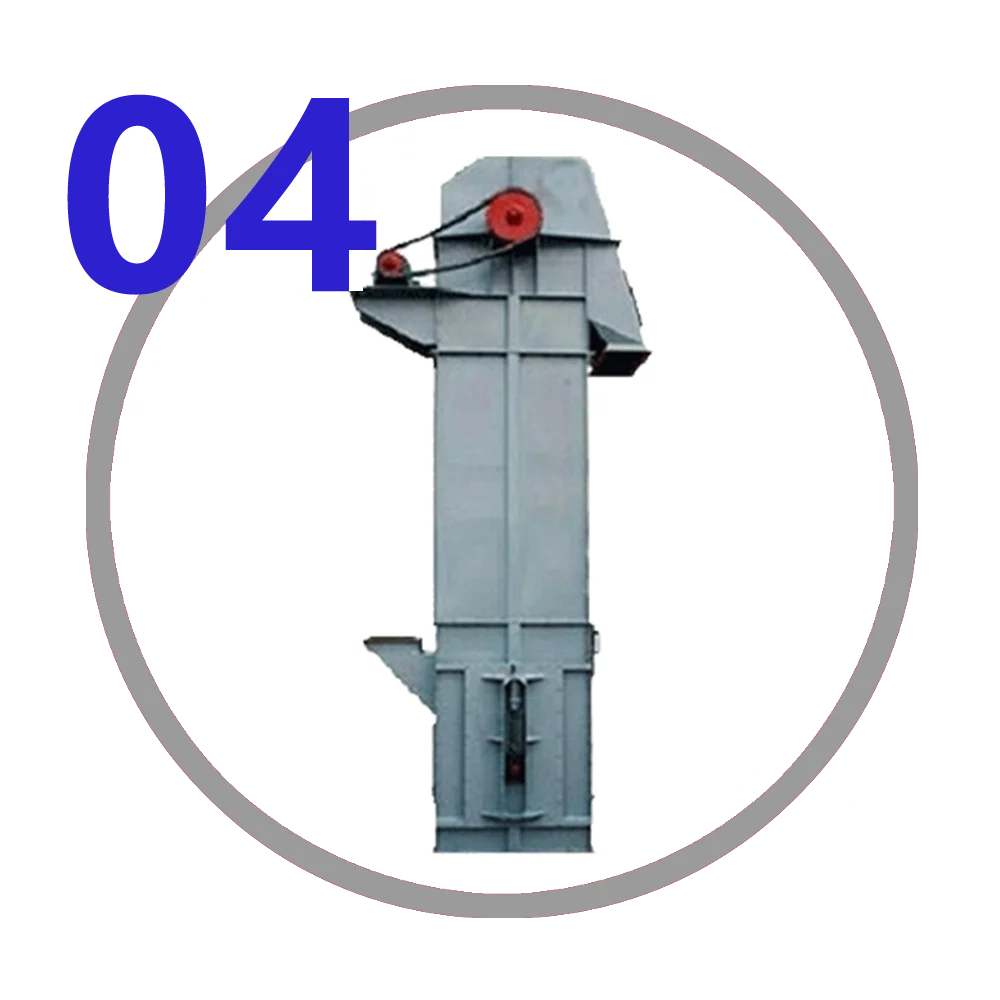

Bucket Elevator

High efficient, Good sealing, Easy assemble, Environment protection, Easy maintenance

This is a vertical lifting device. Lifting height can reach 20-35m, with high efficient lifting speed and large transport capacity, bucket elevator is widely used to lift all kinds of powder or granular material.

Automatic weighting system

High efficient self-measurement, Highly sensitive, High accurate digital display

This is an automatic batching system that greatly saves manpower and material resources. Machine around equips three S-type sensors, which can get exact value when machine running. Input the weight of each raw materials accordingly to the formulation, high precision, reduce weighing error,save labor cost.

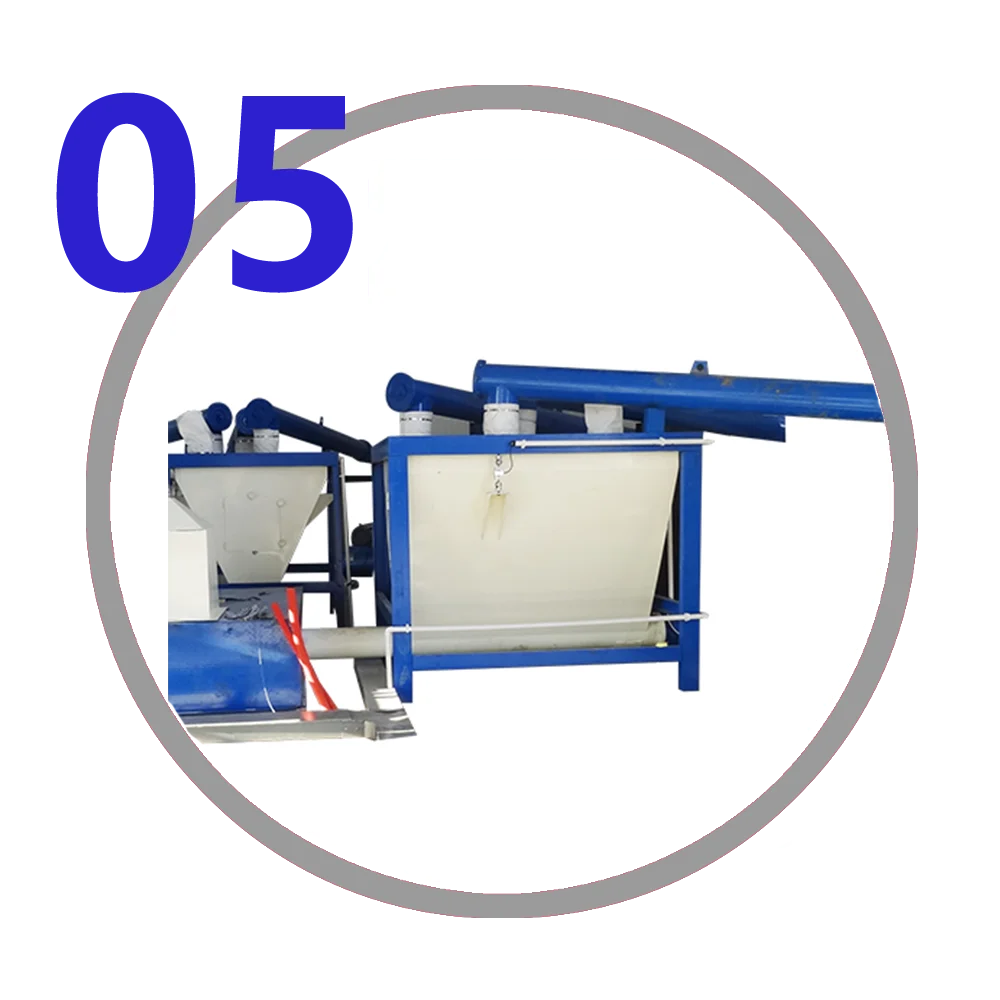

Twin shaft paddle mixer

High Efficiency, equip fly cut for fiber breaking, Mixing time 3-5 minutes per batch

This twin shaft paddle mixer have the characters of high mixing speed, high uniformity, less power consumption. Materials with large differences in physical properties such as specific gravity, particle size, and shape do not easily segregate when mixed in the mixer. The material discharge is by pneumatic control, material can be discharged within 3-5 seconds.

Finish Product Hopper

Reasonable design, Equip pneumatic vibrating system

It is used to storage finish product and fix under the mixer, and also it equip ribbons to realize second mixing, make sure the mixing of product more evenly and product not block when packing.

Packing Machine

High accuracy, high speed, Equip bag auto pushing system

The packing machine use computerized metering devices provides accurate weighing, stable performance and simple operation. And equipped with dust mouth, truly environmentally friendly production. Packing machine is PLC control, more intelligent. It can equip with bag belt conveyor and robot palletizer work.

Impulse dust collector

High efficiency, strength dust collecting, pulse controller control

The Impulse dust collector is mainly designed for dry mortar machine dust collecting, it equips pulse solenoid valve and can realize automatic dust remove. This dust collector is compact in structure, convenient in maintenance, which has the characteristics of large ash removal kinetic energy and high ash removal efficiency.

Screw Type Air Compressor

High Quality, Long life Time, Energy Saving

This screw type air compressor equip Inverter screw host, use good quality copper motor, high efficiency and low noise, equip precise air filter, Industrial grade oil water separator, High accuracy oil filter, high speed heat dissipation system, use import electrical apparatus element, sound insulation cotton.

Control Cabinet

Famous brand PLC, Intelligent and computer control

PLC control system with characters of High degree of intelligence, automatic control from the Raw material storage silo, screw conveyor, weighing of ingredients to the mixing, packaging and full control of the complete set dry mortar plant and easy operation.

Customer Visits

Successful Project

Our Certificates

Our Services

FAQ

1.What's the difference between full automatic dry mortar plant and Semi-automatic dry mortar plant?

A: Semi-automatic dry mortar plant is manual feeding, automatic weighing and packaging and without silos while full automatic type can realize automatic feeding and packaging with silos.

2.How is the quality of your products?

A: Our machines are manufactured strictly according to national and international standards, and we check every small parts before delivery

3.How about the price?

A: We are factory sale and be able to give you the lowest price than the market, and we have policy of time saving and honest, we quote as low as possible for any customer and give discount according to quantity.

4. What equipment and service you can provide?

A: We can provide you turnkey solution of dry mortar plant from working site planning to dry mortar machines, transportation, installation and training, formula of dry mortars, after sales services, life time technical support etc.

5. What is the capacity of your dry mortar plant?

A: We have dry mortar plant capacity from 3-30T/H as your requirement, And also we can customize the machine for you.

6. Can you install the dry mortar plant in my country?

A: Yes, we will send engineers to your country for guiding installation and training your workers to operate the machine.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices