Медицинское оборудование для больниц, 94V0

- Category: >>>

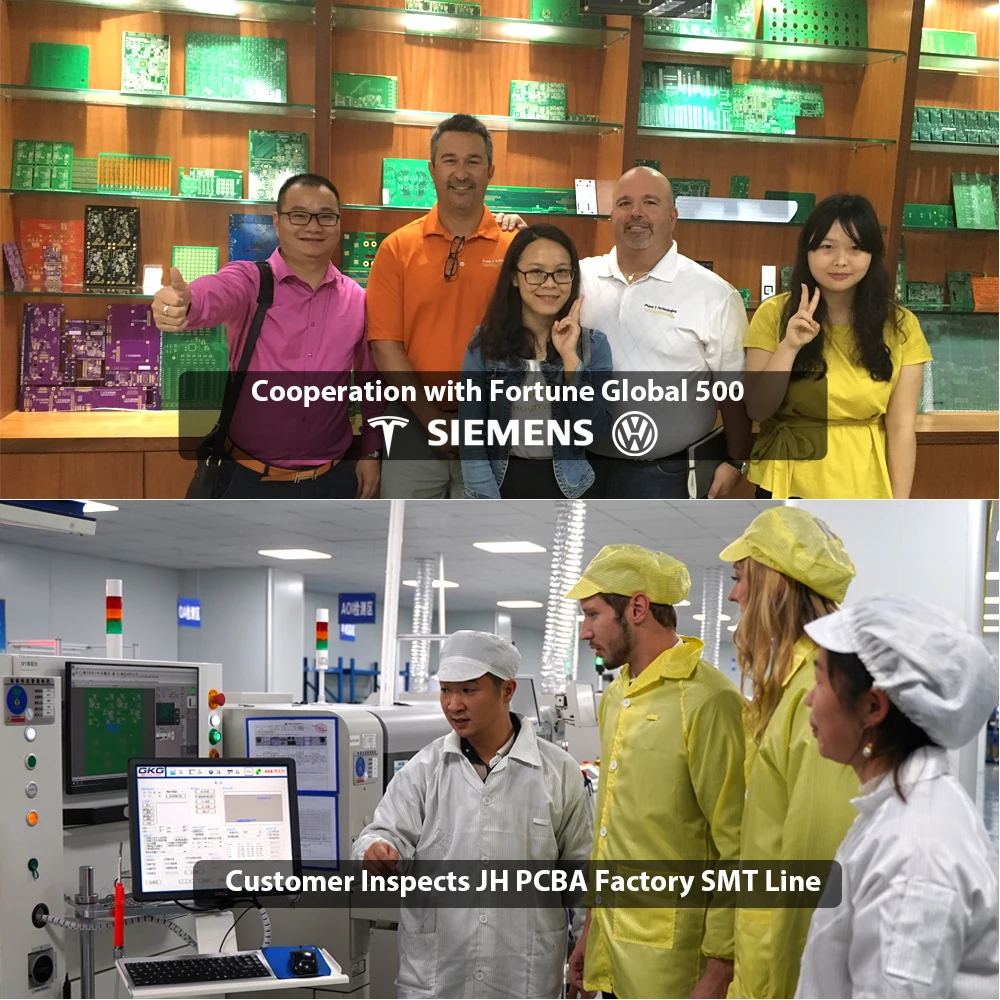

- Supplier: Jinhua Technology (shenzhen) Co. Ltd.

Share on (1600896296579):

Product Overview

Description

No Stock, focus on OEM ODM Service

Professional OEM ODM Manufacturer Medical Equipment

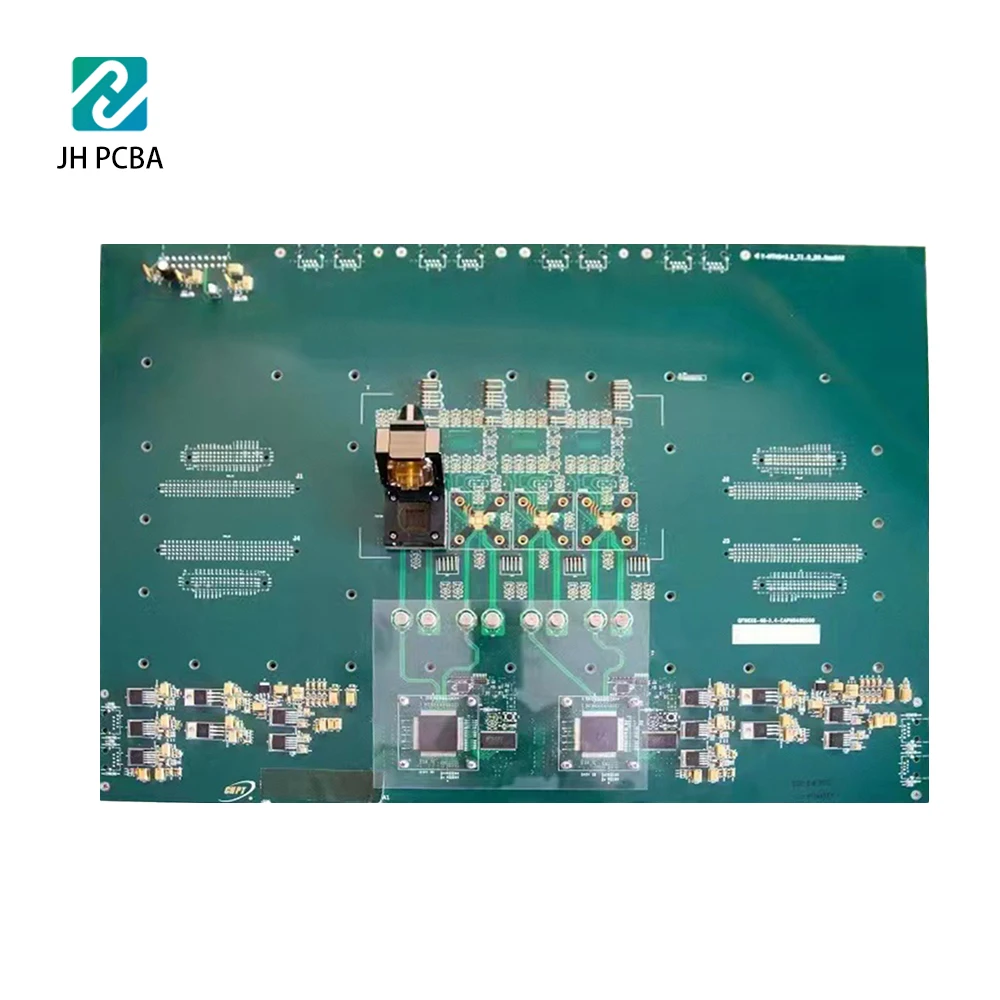

Ultrasound System Blood Analyzer NMR CT Scanner Pcb Board PCBA Assembly

Ultrasound System Blood Analyzer NMR CT Scanner Pcb Board PCBA Assembly

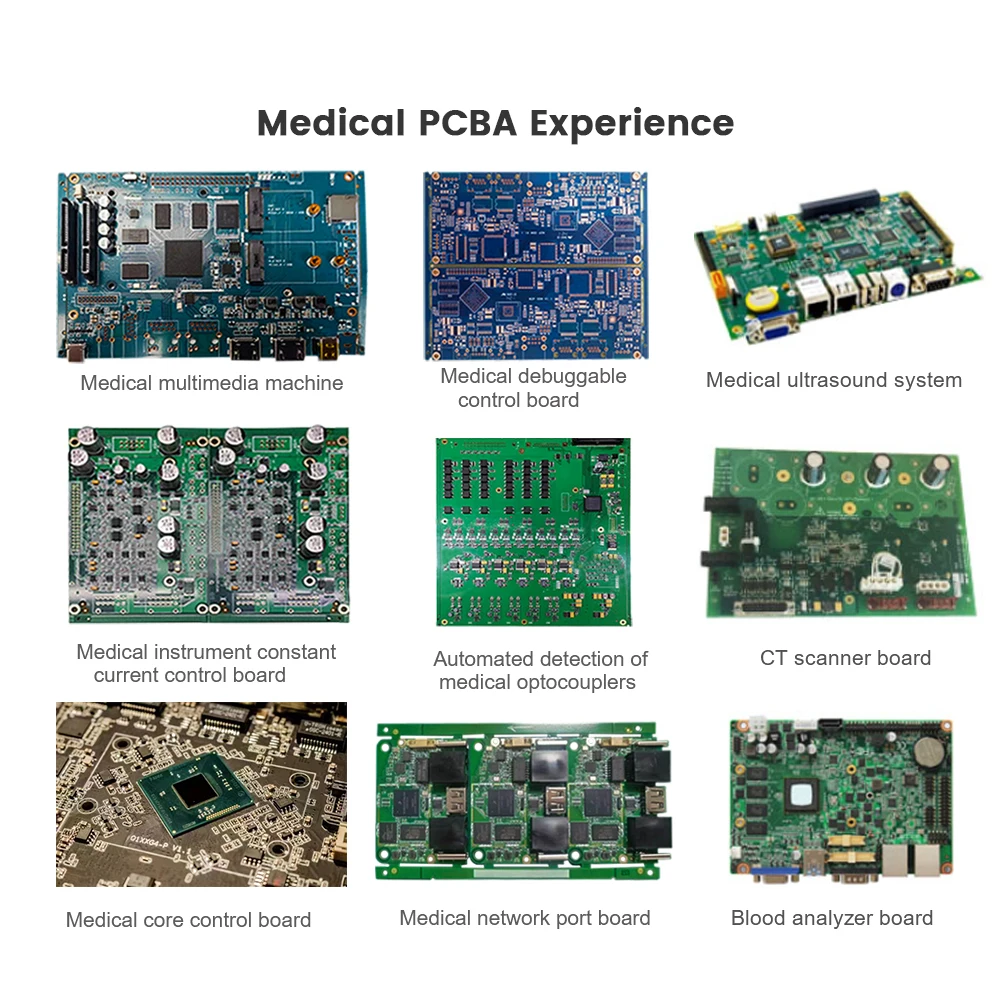

Application Experience

Valuable Services Provided by JINHUA for the Medical Industry.

DC Motor Controller, Speed controller, POV Display Arduino, Car Protection Board. GPS tracker for car, In-Vehicle communication, Car battery monitoring voltmeter. Digital displays, Power relays timing systems, Mirror controls, Scooter battery controller.

JINHUA is a leading name when it comes to providing all-inclusive solutions and services for the medical industry, such as:

PCB assembly for medical equipment

SMT assembly in medical industries

PCB designing for medical industries

PCB inspection and repair for the medical sector

PCB assembly for medical equipment

SMT assembly in medical industries

PCB designing for medical industries

PCB inspection and repair for the medical sector

Customer Factory Inspection

Customer Review

Manufacturer advantage

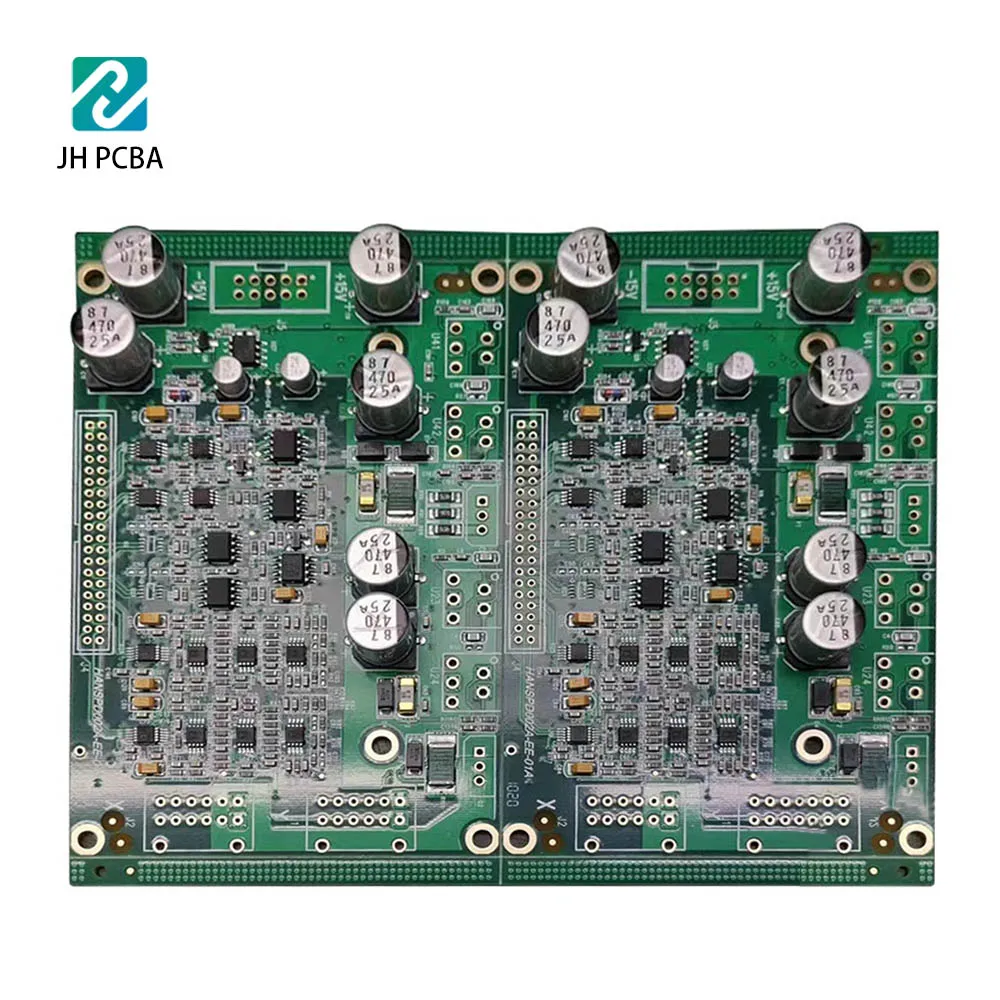

JINHUA SMT Workshop Production Line:

JINHUA DIP Workshop Production Line:

Production Capability :

PCB board size can be assembled: | maximum 480X510mm; minimum size: 50mm x 50mm; |

Smallest Component: | 01005, 0201,0402 |

Minimum BGA: | 0.3mm pitch for rigid PCB, 0.4mm pitch for PCB; |

Fine Pitch component: | 0.3mm pitch |

Component Height Limit: | 15mm |

Assembly Accuracy: | +/-0.025mm |

SMT Production Capacity: | 200-300 million chips/month |

THT Production Capacity: | 13 million chips/month |

Test Capacity: | Depending on customer needs and product conditions |

FAQ

We can offer you PCB Design, PCB board manufacturing, Components or Parts Source, Surface Mount (SMT), Thru-Hole (THT),hybrid of both, Functional Test etc. one stop PCB&PCBA service.

Q2. What is needed for quotation?

Gerber file and Technic requirements (material, surface finish treatment, copper thickness, board thickness, and so on.)

Q3. What file formats do you accept for production?

Gerber Files+BOM File+Centroid File(other names maybe: aka Insertion, Pick-N-Place, or XY Data)

Gerber Files: including files: copper (track), soldermask, silkscreen, solder paste, drill, outline files

Q4. How do you handle the excessive and unused parts?

Excessive parts do exist because we will ask for some percentage of overage for consigned/kitted orders, or we will buy more for the same purpose for those Turn-key orders. You can either ask us to ship back to you these unused parts together with the loaded boards, or keep them in our shelf for your next order. All up to you.

Q5. What is your testing policy and how you control the quality?

As to PCBA production, there are automated optical inspection (AOI) for each batch, X-ray inspection for BGA parts, first article inspection(FAI) before mass production.

Q6. How long does it take for PCBA quote?

Normally 24 hours to 48 hours as soon as receive internal engineer evaluate confirmation.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices