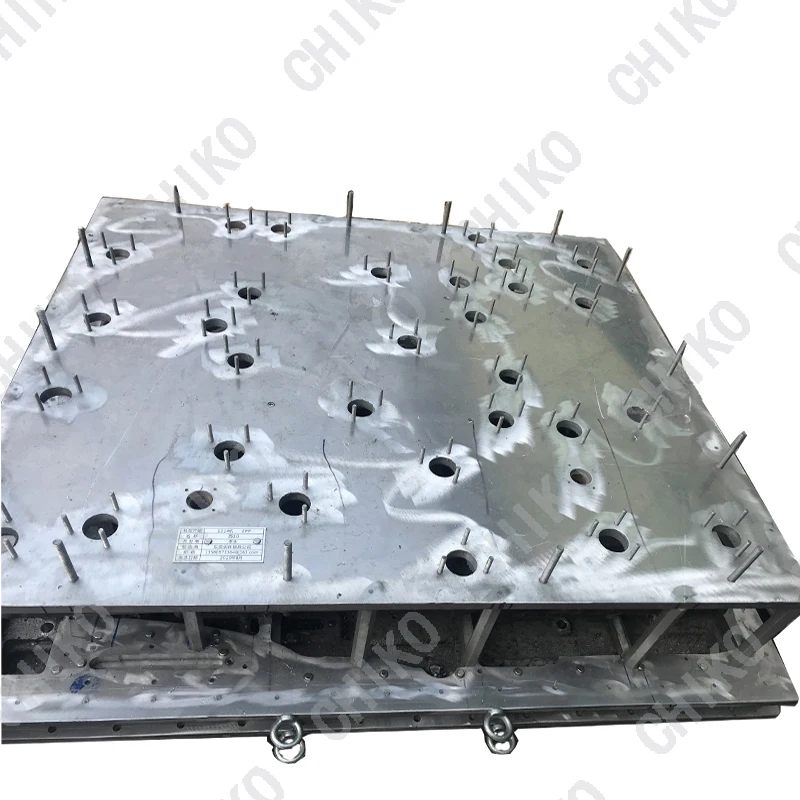

China Wholesale EPS EPP Mould for Lost Foam Casting Mold LFC Aluminum Alloy Styrofoam Mould Manufacturer

- Category: >>>

- Supplier: Chiko Precision Technology (Dongguan) Co. Ltd.

Share on (1600909747528):

Product Overview

Description

Product Description

Product Name | Home Appliance TV Packing OC Packing Foam Mold Cold Chain Transportation EPS Mold Aluminum Alloy Mold For LCD Panel LED TV Foam | |

Category | EPS(styrofoam) mold,EPP mold,EPO mold | |

Application | Packing industry, Home appliance,Consumer Electronics,Toys, Furniture, Aeromodelling, Sporting and etc. | |

Advantage | ||

It Reduced Weight: | the mould is made of Aluminum, it is much lighter than steel. | |

Strengthened: | The foam-like structure produced by foaming moulding makes plastic items stronger and more rigid. As a result, products may be more durable and last longer. | |

Short Lead Time: | only 15-20 days to finish one set of mould. | |

Improved Thermal Insulation: | Plastic components can improve their thermal insulation capabilities by having a foam-like structure formed by the foaming moulding process. | |

Reduced Shrinkage: | Gas can be added during the foaming moulding process to help minimize shrinkage, producing more accurate and exact components. | |

Cost-effectiveness: | This moulding can lead to cost savings since it uses less material, has a faster cycle time, and produces a better product. Due to the decreased weight of the produced plastic pieces, it can also save shipping costs. | |

Eco-friendly: | Foaming moulding is also environmentally friendly since it uses less material and produces less waste. | |

Manufacturing Technique

Production Process

Application

We Recommend

New Arrivals

New products from manufacturers at wholesale prices