Engineering plastics PBT 15% glass fiber reinforced halogen flame retardant PBT resin

- Category: >>>

- Supplier: Xiamen Keyuan Plastic Co. Ltd.

Share on (1600913181443):

Product Overview

Description

Product Description

Glass fiber reinforced PBT (polybutylene terephthalate) plastic is a composite material that is reinforced by mixing PBT with glass fiber. By adding glass fiber reinforcement, the mechanical properties and rigidity of PBT plastics can be significantly improved, while maintaining their excellent insulation, chemical resistance, and heat resistance.

Glass fiber reinforced PBT plastics have a wide range of applications in many fields, including electronic and electrical, automotive, aerospace, industrial manufacturing, and so on. The following are some applications of glass fiber reinforced PBT plastics:

1. Electronic and electrical equipment: Glass fiber reinforced PBT plastic is commonly used in sockets, connectors, insulation parts, and electronic components in electronic and electrical equipment. Its high strength and heat resistance make it an important material in electronic devices.

2. Automotive and Transportation: Glass fiber reinforced PBT plastic is widely used in the automotive and transportation fields, including engine components, headlights, sensors, cable protective sleeves, etc. Its high strength and heat resistance make it suitable for applications in high-temperature environments.

3. Industrial manufacturing: Glass fiber reinforced PBT plastic is used in the industrial manufacturing field to manufacture components such as gears, bearings, pump bodies, valves, and pipelines. Its rigidity and wear resistance make it an ideal choice for applications that require durability and mechanical strength.

4. Other fields: Glass fiber reinforced PBT plastic can also be applied in furniture manufacturing, building materials, outdoor equipment, and other fields to meet specific strength and durability requirements.

Product Name | Virgin And Recycled PBT Granule |

Material | PBT |

Color | As requirement |

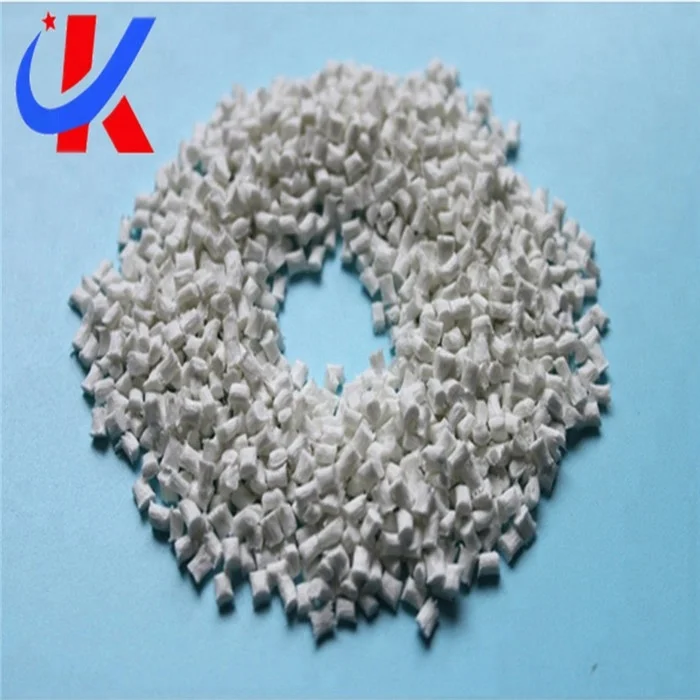

Brand | KEYUAN |

Grade | Injection grade / extrusion grade / film grade /raffia grade etc |

Properties | Reinforced with glass fiber,toughness,fire retardant,mos2,conductive etc |

Advantage | High quality and competitive price |

Package | 25kgs/bag,1000kgs/bag etc |

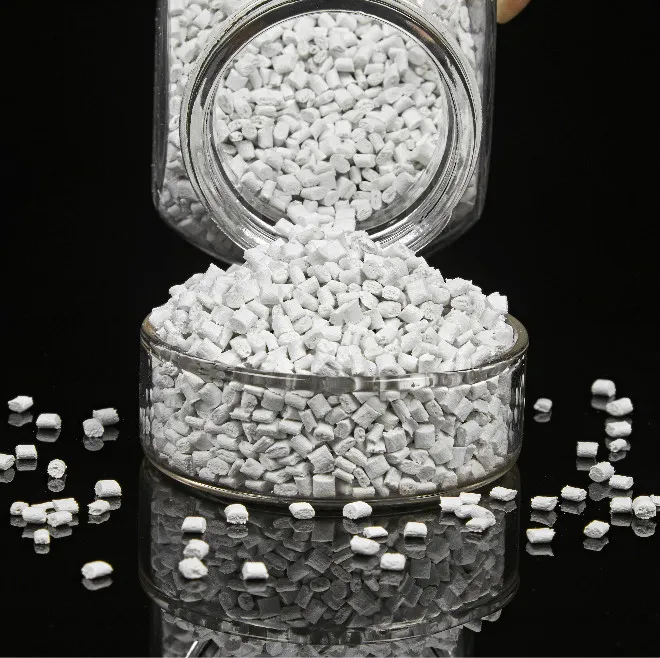

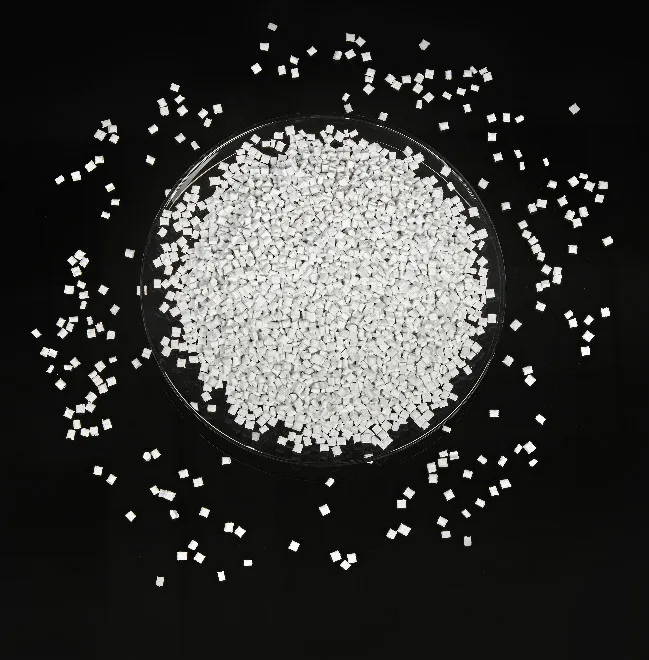

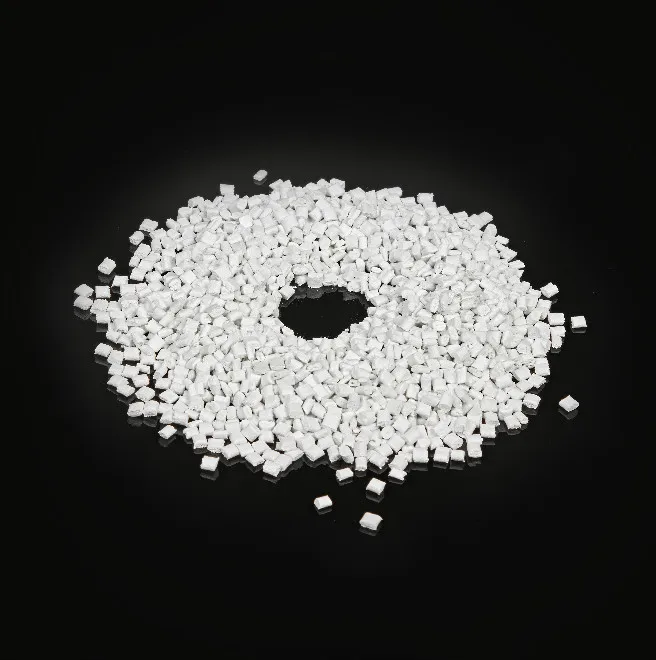

Products Show

Application

Applications

1. Architecture Decoration Industry

2. Transportation Industry, Advertisement Industry

3. Home Electrical Appliance, Computer and Instrument Equipments

4. Electric & Electrical, Chemical Machinery, Automobile Industry

Our Certifications

Our Company

Team

Our Team

Team

Our Team

Packing & Delivery

Packing Details : Standard Packing(Inner (Plastic film) Outer(Paper bag or woven bag)

Delivery Details : 5-10 days after order

Packaging Details:25kg/bag

Port:XIAMEN

Lead Time :7~15 working days after payment

We Recommend

New Arrivals

New products from manufacturers at wholesale prices