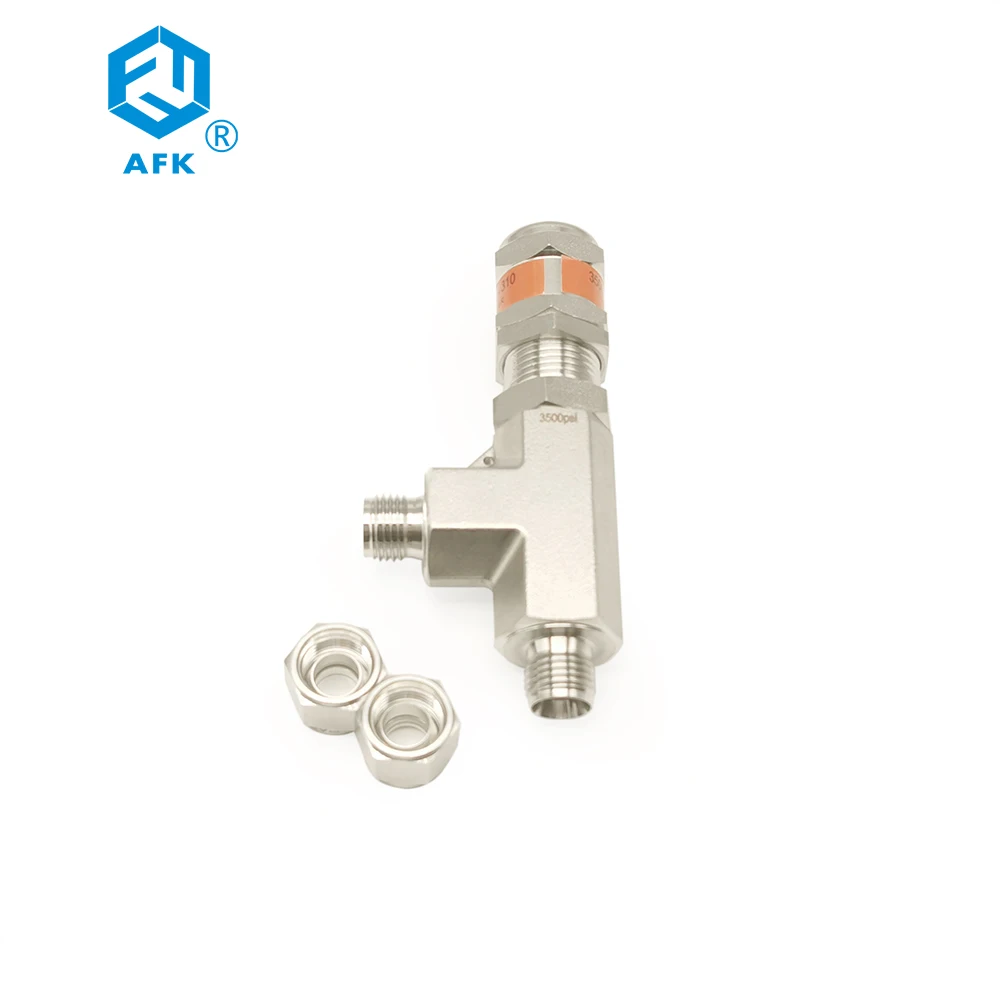

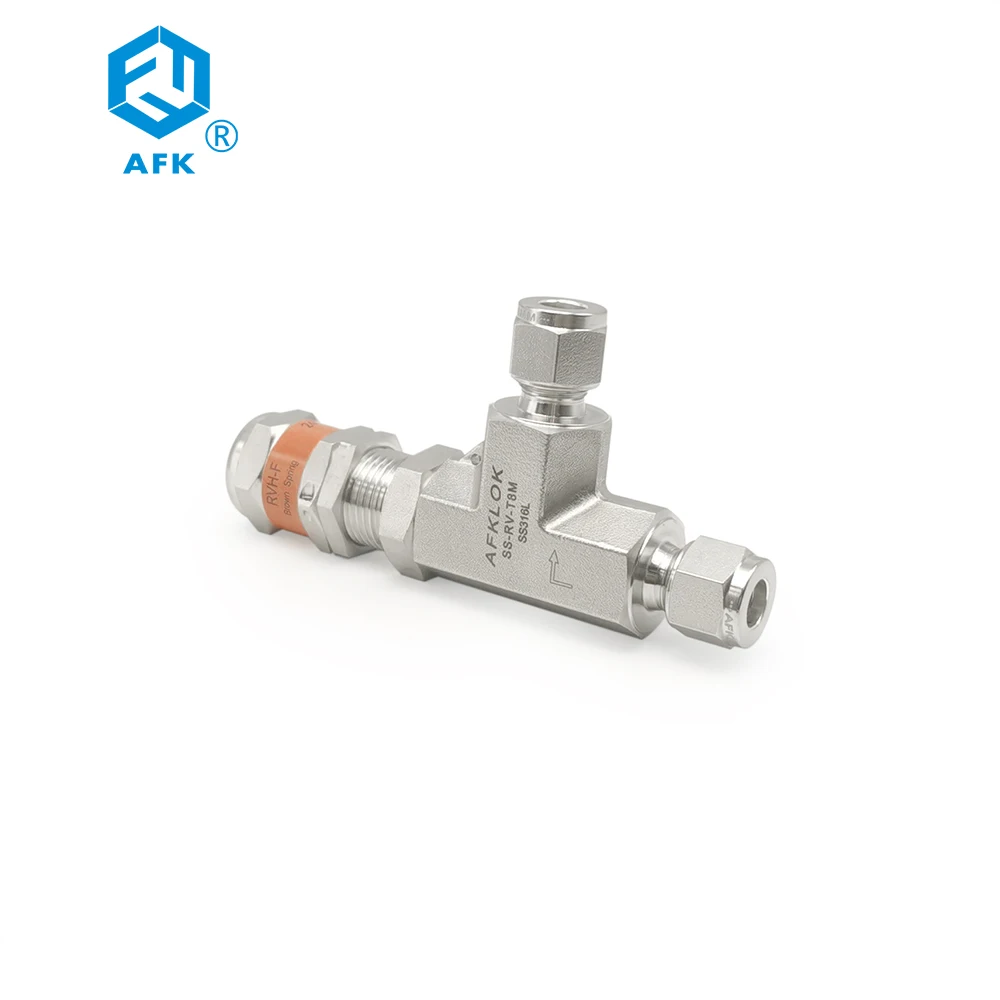

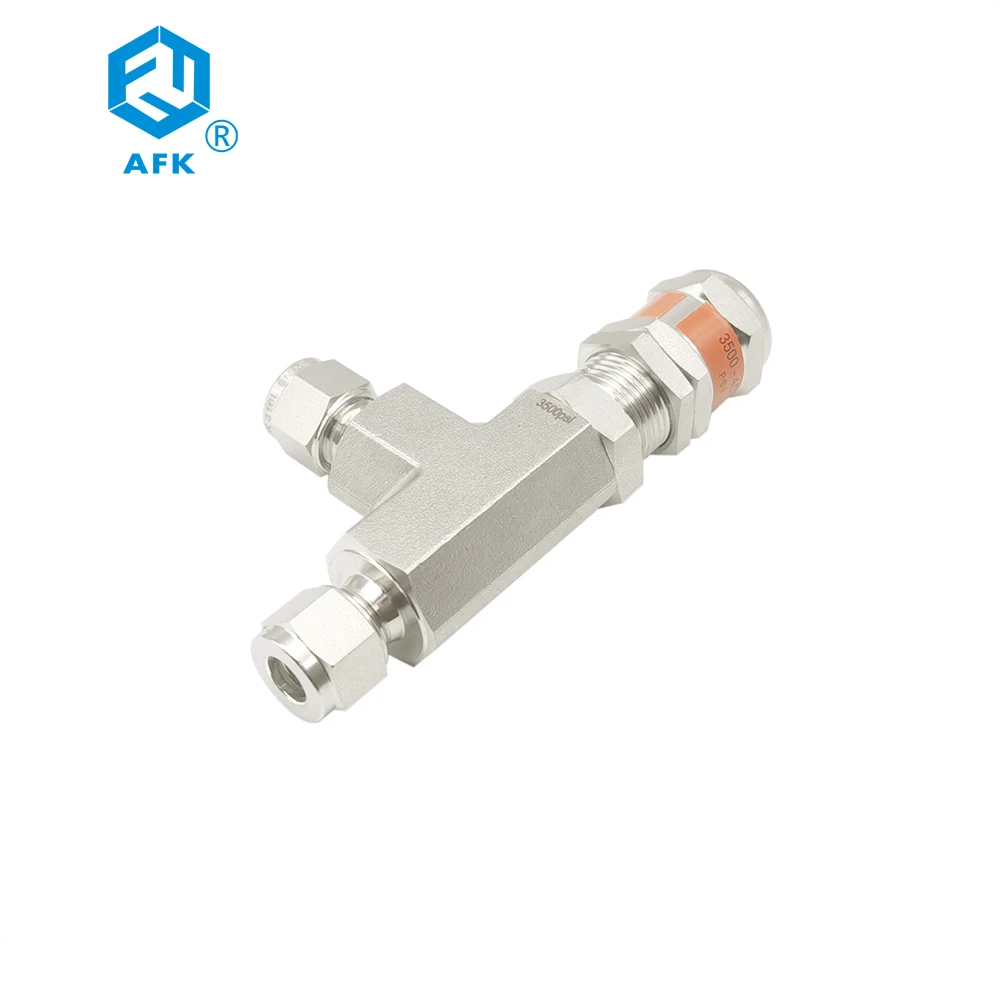

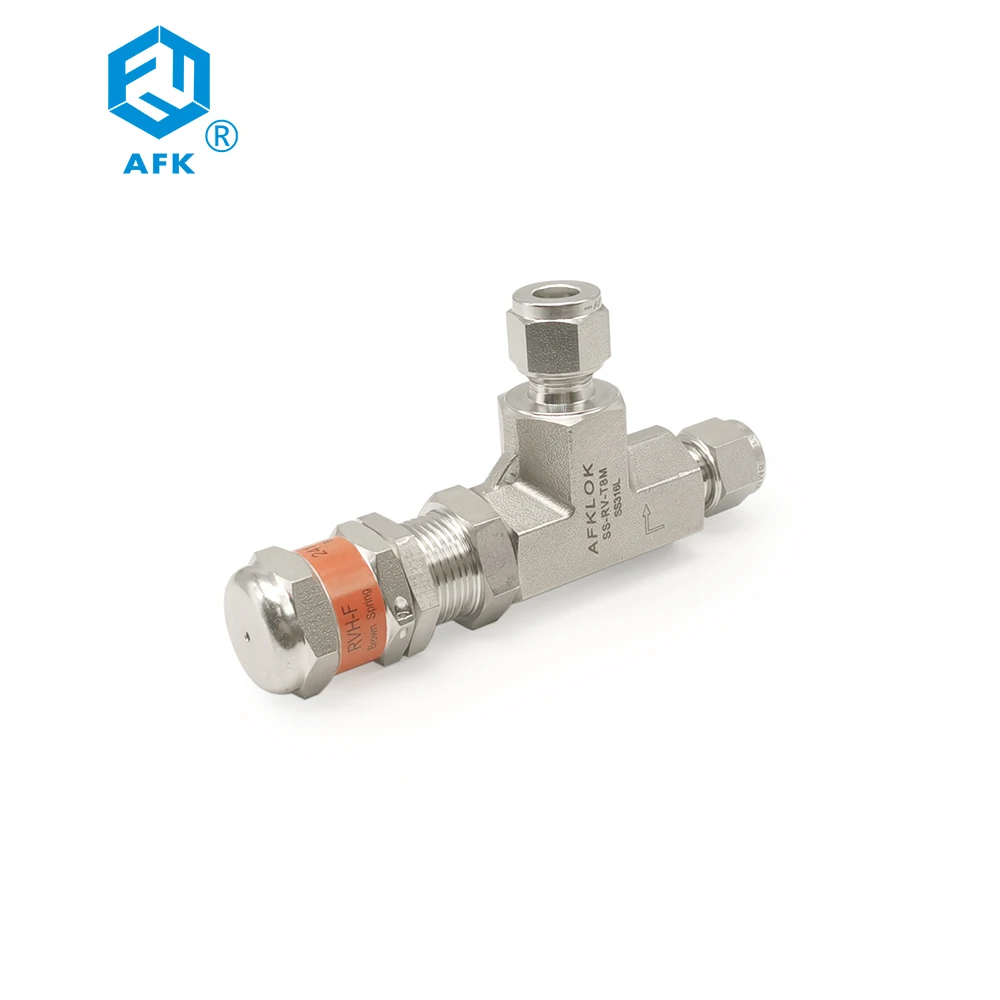

1/2in Safety Relief Valves High Pressure Air Stainless Steel Relief Valve Proportional Relief Valve 6000psi

- Category: >>>

- Supplier: Shenzhen Wofly Technology Co. Ltd.

Share on (1600920164445):

Product Overview

Description

Product Description

Specification

Brand Name | AFKLOK |

Model Number | RV |

Application | General |

Temperature of Media | High Temperature |

Power | Manual |

Media | Gas Water |

Port Size | 1/4in-1in |

Structure | Safety |

Product name | air release valve |

Material | 316 stainless steel |

Certificate | ISO 9001:2015 |

Port Size | 1/8 to 3/4, 1/8 to 3/4 |

Orifice size | 0.14in |

Maximum working pressure | 6000 psig |

MOQ | 1 Pcs |

End connection | Ferrule |

Seal Material | fluorocarbon, buna N,Ethylene, neoprene |

Color | Silver |

MATERIALS OF CONSTRUCTION | ||||||

Item No. | Components | Qty | Valve Body Materia | |||

1 | Cap Plug | 1 | Polypropylene | |||

2 | Adjustment Cap | 1 | St.St.316 | |||

3 | Cap Lable | 1 | Polyester | |||

4 | Locking Nut | 1 | St.St.316 | |||

5 | Upper Spring Button | 1 | St.St.316 | |||

6 | Spring | 1 | St.St.302 | |||

7 | Lower Spring Button | 1 | St.St.316 | |||

8 | Bonnet | 1 | St.St.316 | |||

9 | O-ring | 1 | FluorocarOn EKM | |||

10 | O-ring | 1 | Fluorocarbon FKM | |||

11 | Retaining Ring | 1 | PH15-7 Mo | |||

12 | Stem | 1 | St.St.316 | |||

13 | Bonded Poppet | 1 | St.St.316StSt. 316 Bonded with Fluorocarbon FKM | |||

14 | Insert | 1 | St.St.316 | |||

15 | Packing | 1 | PTFE | |||

16 | Ring | 1 | St.St.316 | |||

17 | Body | 1 | St.St.316 | |||

Packing & Delivery

inner box packing +white box packing+ export carton

Company Profile

WOFLY is a leading Manufacturer, Supplier and Exporter of a wide range of gas equipements, available under the brand name AFK. Wofly's success yields from high-quality, innovative products, exceptional customer service, and unequaled technical expertise in the gas& oil industry.

WOFLY offers an extensive line of components including tube fittings, control valves, shut-off and solenoid valves, pressure relief and regulators.Through the years we have learned how to properly match the gas regulation equipment with the application. Using the proper equipment for the job eliminates problems such as contamination, pressure variances, safety issues, and equipment mismatch.

WOFLY offers an extensive line of components including tube fittings, control valves, shut-off and solenoid valves, pressure relief and regulators.Through the years we have learned how to properly match the gas regulation equipment with the application. Using the proper equipment for the job eliminates problems such as contamination, pressure variances, safety issues, and equipment mismatch.

Customers WOFLY沃飞科技

Applicable Scenarios

The main purpose of air release valves is to eliminate trapped air or gas and promote efficient and reliable operation of fluid systems in various industries.

The fields of application are:

Water Distribution Systems,Irrigation System,Wastewater and Sewage Systems,Hydropower Systems,Fire Protection Systems,HVAC Systems,Chemical Processing ect.

FAQ

Q. Are you manufacturer?

A. Yes, we are manufacturer.

A. Yes, we are manufacturer.

Q. What is lead time?

A. 3-5days. 7-10 days for 100pcs

Q. How do I order?

A. You can order it from Alibaba directly or send us a inquiry. We will reply you within 24 hours

A: A safety valve is a device used to protect a pressure vessel or system from excessive pressure. It will open when the pressure exceeds a set value, releasing the excess pressure to prevent rupture or damage to the vessel or system.

Q: Why are safety valves important?

A: Safety valves are critical components that protect the safe operation of pressure vessels and systems. They ensure that pressures do not exceed set ranges and prevent excessive pressures that could lead to accidents, explosions or leaks.

Q: What is the working principle of a safety valve?

A: Safety valves work by adjusting the balance between spring force and medium pressure. When the pressure exceeds the set value, the spring is compressed, causing the valve to open and release the excess pressure. Once the pressure returns to within the set range, the valve closes and keeps the pressure stable.

A: Safety valves work by adjusting the balance between spring force and medium pressure. When the pressure exceeds the set value, the spring is compressed, causing the valve to open and release the excess pressure. Once the pressure returns to within the set range, the valve closes and keeps the pressure stable.

Q: How do I select the proper type and size of safety valve?

A: Selection of the proper type and size of safety valve depends on the specific requirements of the application, including vessel or system operating pressure, media type, flow requirements and environmental conditions.

A: Selection of the proper type and size of safety valve depends on the specific requirements of the application, including vessel or system operating pressure, media type, flow requirements and environmental conditions.

Q: Do safety valves require maintenance?

A: Yes, safety valves require regular maintenance and inspection to ensure proper operation and reliability. Maintenance includes cleaning, calibrating, checking seals and valve components for wear, and documenting maintenance records. It is recommended to follow the maintenance guidelines provided by the manufacturer.

Q: How are safety valves calibrated and tested?

A: Safety valves should be calibrated and tested periodically to ensure that they respond accurately over their normal operating pressure range. Testing typically involves pressure testing the valve with calibration equipment and checking its opening and closing accuracy. Calibration and testing should be carried out by an experienced professional or an organization that meets the relevant standards.

Q: How can I tell if a safety valve needs to be replaced?

A: Safety valves may need to be replaced after service life, frequent operation, or experiencing excessive pressure conditions. Replacement should also be considered if the safety valve cannot be calibrated, tested or maintained to restore its proper function. It is recommended that the manufacturer's recommendations and relevant standards be followed.

A: Yes, safety valves require regular maintenance and inspection to ensure proper operation and reliability. Maintenance includes cleaning, calibrating, checking seals and valve components for wear, and documenting maintenance records. It is recommended to follow the maintenance guidelines provided by the manufacturer.

Q: How are safety valves calibrated and tested?

A: Safety valves should be calibrated and tested periodically to ensure that they respond accurately over their normal operating pressure range. Testing typically involves pressure testing the valve with calibration equipment and checking its opening and closing accuracy. Calibration and testing should be carried out by an experienced professional or an organization that meets the relevant standards.

Q: How can I tell if a safety valve needs to be replaced?

A: Safety valves may need to be replaced after service life, frequent operation, or experiencing excessive pressure conditions. Replacement should also be considered if the safety valve cannot be calibrated, tested or maintained to restore its proper function. It is recommended that the manufacturer's recommendations and relevant standards be followed.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices