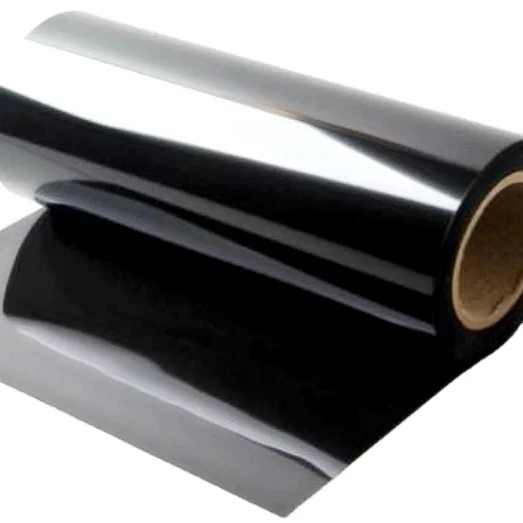

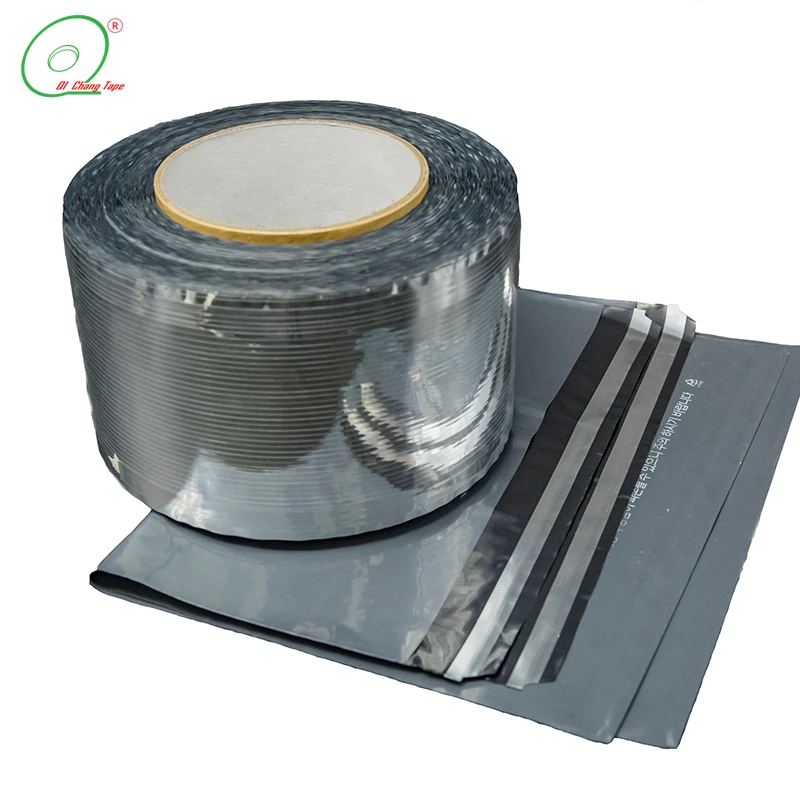

Thermal Conductive Heat Dissipation Sheet Graphite Rolls Graphite Sheets

- Category: >>>

- Supplier: Shenzhen Leaderway Adhesive Technology Co. Ltd.Shenzhen Ltd.

Share on (1600925986277):

Product Overview

Description

Product name | graphene sheet |

Material | Synthetic graphite film |

Thickness | 0.07mm |

Temperature resistance range | -50℃~450℃ |

Thermal resistance | 0.15%(℃) |

Thermal conductivity | 1500W/m.k |

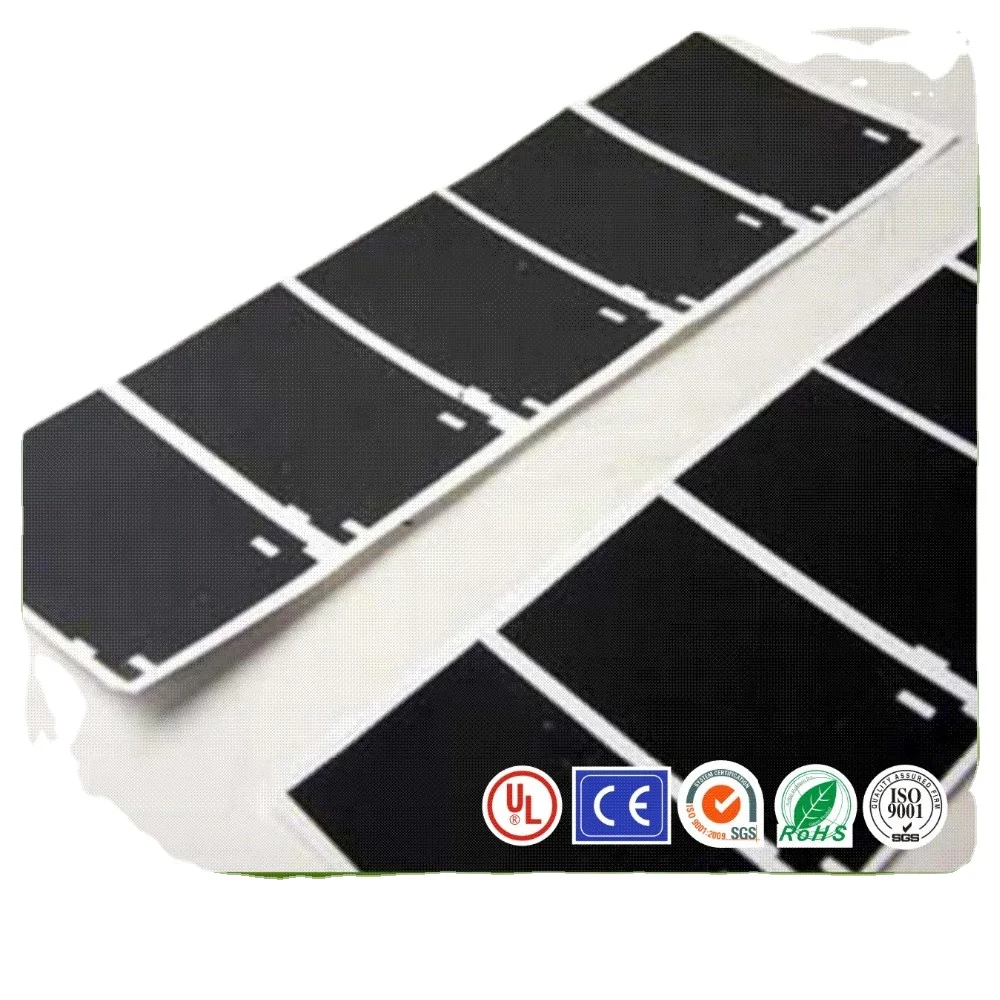

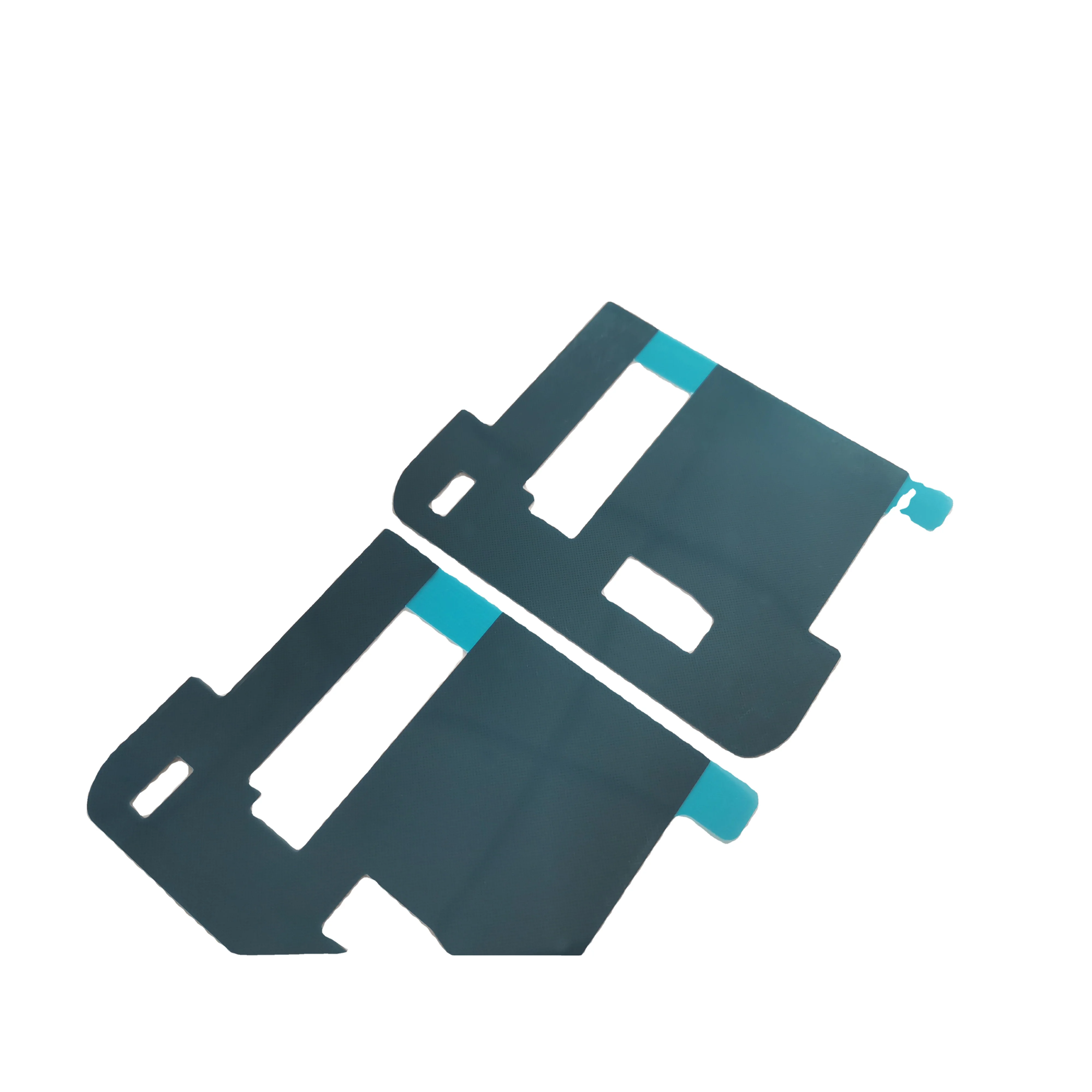

Product Performance | It is widely used in important emerging industries such as new energy, energy saving transformation, etc. With the improvement of the performance of electronic chips, the heat dissipation performance of mobile phones, tablets and ultra-thin laptops is very important. The application of graphene materials can improve the concentration of hot spots, achieve the effect of sharing heat on the plane and increase the heat dissipation area, reduce chip temperature |

Main features | Super high thermal conductivity,easy processing,bottom thermal resistance,high reliability, light weight,environmental protection, etc. |

Application example | Mobile phone, computer, communication equipment, Led, heat sink, LCD-TV, etc. |

Q: How long is the validity period of graphite ?

A: Long-term use.

Q:How is the effect of graphite pasting?

A:According to the experimental test, the chip temperature can be reduced more than 10 °.

Q: Do you provide samples?

A: Yes, we do.

Q: Can you provide finished product processing service?

A: Yes, we can prodive the finished product after die-cutting.

Q: What is the leadtime for mass production?

A: 7-20 days.

This product is customized. In order to provide you with the most suitable product, please consult customer service to inform you of the requirements of the product before purchase.

♦ Contact Us ♦

sally xia

Mail:sl_xia@szleaderway.com

Mob : +86-185-0276-7565 (Whatsapp , Wechat)

www.szleaderway.com

Product name | graphene sheet |

Material | Synthetic graphite film |

Thickness | 0.07mm |

Temperature resistance range | -50℃~450℃ |

Thermal resistance | 0.15%(℃) |

Thermal conductivity | 1500W/m.k |

Product Performance | It is widely used in important emerging industries such as new energy, energy saving transformation, etc. With the improvement of the performance of electronic chips, the heat dissipation performance of mobile phones, tablets and ultra-thin laptops is very important. The application of graphene materials can improve the concentration of hot spots, achieve the effect of sharing heat on the plane and increase the heat dissipation area, reduce chip temperature |

Main features | Super high thermal conductivity,easy processing,bottom thermal resistance,high reliability, light weight,environmental protection, etc. |

Application example | Mobile phone, computer, communication equipment, Led, heat sink, LCD-TV, etc. |

Q: How long is the validity period of graphite ?

A: Long-term use.

Q:How is the effect of graphite pasting?

A:According to the experimental test, the chip temperature can be reduced more than 10 °.

Q: Do you provide samples?

A: Yes, we do.

Q: Can you provide finished product processing service?

A: Yes, we can prodive the finished product after die-cutting.

Q: What is the leadtime for mass production?

A: 7-20 days.

This product is customized. In order to provide you with the most suitable product, please consult customer service to inform you of the requirements of the product before purchase.

♦ Contact Us ♦

sally xia

Mail:sl_xia@szleaderway.com

Mob : +86-185-0276-7565 (Whatsapp , Wechat)

www.szleaderway.com

We Recommend

New Arrivals

New products from manufacturers at wholesale prices