YQ32 1200 ton wooden chips pallet tray forming hydraulic press

- Category: >>>

- Supplier: Tengzhou Dingrun Forging Machinery Plant

Share on (1600926535102):

Product Overview

Description

YQ32-1200 ton wooden chips pallet tray forming hydraulic press

Products Description

Characteristic:

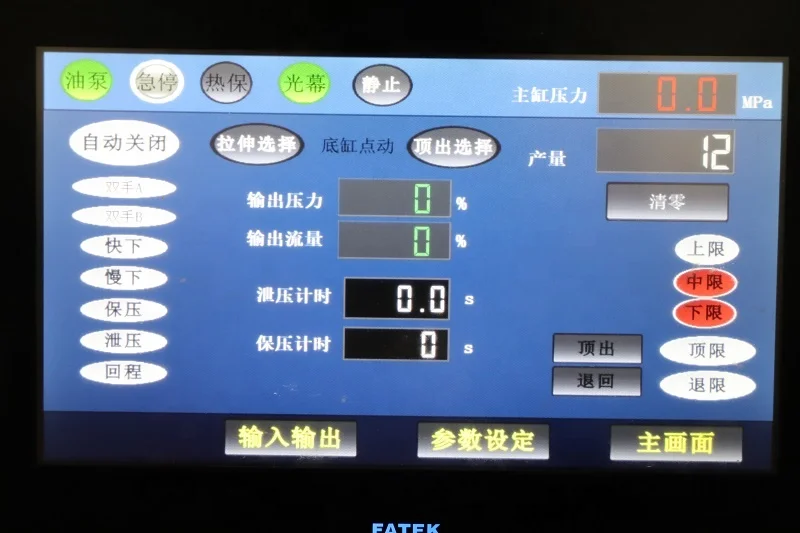

YQ32-1200 ton wooden chips pallet tray forming hydraulic press making hydraulic press with three beam four column structures,Specially made large worktable according to customer needs,different tonnage.Hydraulic control adopts to insert set valve integrated system, decrease let out Point , Movement reliability, durable and long life span ,It is constant pressure to realize with calm in the first place and calm procedure two develop technology, have to insure press the function of delay time , The route of working pressure may be regulated in assigned scope ,adopt buttons for centralized control,Can realization manual,Semi-automatic,automatic 3 operate form.

Product Paramenters

Project | 250t | 315t | 500t | 1000t |

Max liquid working pressure | 25 | 25 | 25 | 25 |

Slide stroke | 400 | 400 | 600 | 900 |

Max opening height | 800 | 700 | 1000 | 1500 |

Worktable size | 660*660 | 700*700 | 1000*1000 | 1500*1500 |

Descent speed | 30 | 60 | 100 | 120 |

Working speed | 8-12 | 6-12 | 6-15 | 6-12 |

Return speed | 20 | 60 | 80 | 80 |

Motor power | 7.5 | 11 | 37 | 37*2 |

Finished Products

According to your needs to choose different tonnage different table machines.

Detailde imdges

2.In the process of high-pressure washing,red copper can effectively protect the rubber skin from breakage.

2.Reduce the impact on the pipeline when the oil is pumped out,and it is more difficult to leak.

Packing&Delivery

YQ32-1200 ton wooden chips pallet tray forming hydraulic press

Surface with anti-rust treatment,inner layer of plastic waterproof packaging,outer layer of thick wood or steel frame fixed,Andthen use a synthetic board package.

Combined container transport, or separate container transport.

Delivery Detail:Shipped in 45 days after payment(Accoording to different types)

Company Profile

Tengzhou Dingrun Forging Machinery Factory is a company that specializing in the research and development, design,production and after-sales service of large and medium-sized hydraulic machinery equipment. Its strength ranks in the forefront of the industry, and its products are exported to Canada, the United States, and Chile. ,Peru, South Korea, Vietnam, Southeast Asia,India, Pakistan, Saudi Arabia, Australia, Egypt, Turkey, United Kingdom, Poland,Norway, Belgium, Syria,Ukraine,Ukraine,Russia,Uzbekistan and other countries.The annual output value is 150 million yuan and the plant is more than

20,000 square meters. Now it has more than 120 employees, including 5 engineers and 2 senior engineers. It has successfully applied for more than ten national patents, and many papers have been included in the United States Engineering Information Corporation, the most famous information company in the world of engineering and applied sciences. EI database.The company's predecessor was a 15-year-old Zhonghe Machinery Factory. Its main products include universal four-post hydraulic presses,single-arm hydraulic presses, gantry frame hydraulic presses and hydraulic punches.

20,000 square meters. Now it has more than 120 employees, including 5 engineers and 2 senior engineers. It has successfully applied for more than ten national patents, and many papers have been included in the United States Engineering Information Corporation, the most famous information company in the world of engineering and applied sciences. EI database.The company's predecessor was a 15-year-old Zhonghe Machinery Factory. Its main products include universal four-post hydraulic presses,single-arm hydraulic presses, gantry frame hydraulic presses and hydraulic punches.

Certifications

International CE certification, Alibaba / China manufacturing network SGS certification.

FAQ

Q:How about your machine quality?

We are worry about the quality.A:Dingrun is a mature brand in China. through our several years research in technology , our design including strcture and detailed sercurity and precision has enhanced greatly, and can match all the CE standard or mor strict standard.Our machines distribute worldwide to about 20 countries where there are metal plate industry.And where there are our machines, there are good reputation and terminal user satisfaction.

Q:Why Choose your company?

A:We can provide customized services according to customer requirements. We also have professional R &D team and fast response sales team. Strictly control each step of QA &QC system processes. We have an after sale service team than can quickly solve any problem you may have in the use.

Q:How to select your machine?

A: You can tell me your specifications ,we can choose the best model for you . we also have some regular model for you to

choose.You can also provide the drawings, size , photos of the products, we can design the suitable machine for you according to your requirements. After the machine is finished, you can also provide samples and we will test it for you.

We are worry about the quality.A:Dingrun is a mature brand in China. through our several years research in technology , our design including strcture and detailed sercurity and precision has enhanced greatly, and can match all the CE standard or mor strict standard.Our machines distribute worldwide to about 20 countries where there are metal plate industry.And where there are our machines, there are good reputation and terminal user satisfaction.

Q:Why Choose your company?

A:We can provide customized services according to customer requirements. We also have professional R &D team and fast response sales team. Strictly control each step of QA &QC system processes. We have an after sale service team than can quickly solve any problem you may have in the use.

Q:How to select your machine?

A: You can tell me your specifications ,we can choose the best model for you . we also have some regular model for you to

choose.You can also provide the drawings, size , photos of the products, we can design the suitable machine for you according to your requirements. After the machine is finished, you can also provide samples and we will test it for you.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices