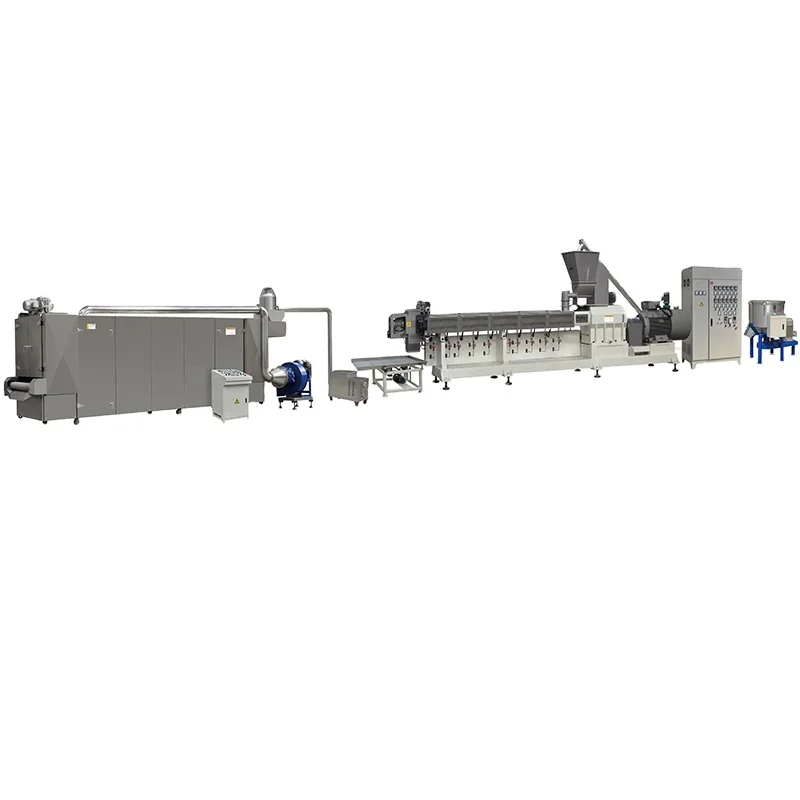

double helix extruder for nutritional rice fortified artificial rice nutrition rice making extruder plant

- Category: >>>

- Supplier: Jinan Dayi Extrusion Machinery Co. Ltd.Jinan Ltd.

Share on (1600928256185):

Product Overview

Description

Product Application

This artificial rice process line uses rice as the main raw material, and some other vitamin and mineral material can be chosen as the products required.The material is extruded into rice shape by the double-screw extruder, dried to need moisture content,and eaten after boiled 5-8min. The extruding technique makes it possible strengthen the micronutrient in the rice and solidify it.

Model | Installed Power | Power Consumption | Capacity | Dimension |

SLG65-CJ | 53.52kw | 34.8kw | 100-150kg/h | 16200*1200*2200mm |

SLG75-A | 127.24kw | 82.7kw | 200-300kg/h | 19780*2100*2300mm |

SLG72-E | 489.77kw | 342.84kw | 700~900kg/h | 59900*9000*7000mm |

Main Features

①Direct tranmission between motor and gear box,reducing energy loss.

② Modular combination of screws can be satisfied to different raw materials.

③Barrel with water injecting device, and automatic heating and circulating cooling system can make accurate temperature.

④ Inverters control feeder,cutter,and main driving motor strongly and stably.

⑤ Hanging mould and cutter base on line bearing adjusting device.

⑥Adopted import bearing sets with stronger bearing capacity.

⑦Automatic lubricating system reduces the power consumption and prolongs using life.

Machine Features

Name: Flour Mixer III

Model:BF-III

Capacity:100kg/h

Motor:5kw

Brand: Jinan Dayi Extrusion Machinery Co.,ltd

Original: Jinan,Shandong,China.

To Mix up the raw material equally.

Main Features

Model:SLG75-A

Capacity:200-300kg/h

Motor:127kw

Brand: Jinan Dayi Extrusion Machinery Co.,ltd

Original:

Jinan,Shandong,China.

1) Direct tranmission between motor and gear box,reducing energy loss.

2) Modular combination of screws can be satisfied to different raw materials..

3) Barrel with water injecting device, and automatic heating and circulating cooling system can make accurate temperature.

Machine Features

Name: Cooling Vibrator

Model:TLJ-I

Motor:0.36kw

Brand: Jinan Dayi Extrusion Machinery Co.,ltd

Original: Jinan,Shandong,China.

To vibrate the rice in case they stick together and convey them to next equipment.

Main Features

Name: Air Convey

Model:FJ-I

Motor:1.1kw

Brand: Jinan Dayi Extrusion Machinery Co.,ltd

Original: Jinan,Shandong,China.

To convey the rice to Dryer.

Machine Features

Name: Five Layer Dryer

Model:WHX

Capacity:200-300kg/h

Heating Energy:Gas,Diesel or Electric

Brand: Jinan Dayi Extrusion Machinery Co.,ltd

Original: Jinan,Shandong,China.

To dry out the extra moisture inside of rice.

A1: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q2: What is your terms of delivery?

A2: EXW, FOB, CFR, CIF.

Q3: How about your delivery time?

A3: Generally, most of items we keep stock for all season . it will take 7 to 10 days after receiving your advance paymentif we didn't have stock ,The delivery time depends on the items and the quantity of your order. Normaly 30 to 60days.

Q4: Do you inspect all your goods before delivery?

A5: Yes, we have 100% test before delivery

We Recommend

New Arrivals

New products from manufacturers at wholesale prices