Professional Iron Ore Beneficiation Plant Iron Ore Processing Mining Machinery Magnetite Separation Production Line

- Category: >>>

- Supplier: Henan Zoomjo International Trade Co. Ltd.Henan Ltd.

Share on (1600930607280):

Product Overview

Description

Professional Iron Ore Beneficiation Plant Iron Ore Processing Mining Machinery Magnetite Separation Production Line

Product Description

small scale mineral processing plants---gold, silver, copper, zinc, lead, ore, iron, manganese ore

With the continuous development of mineral processing technology, the mineral processing technology for different types of iron ore has also undergone significant changes, and the mineral processing indicators have also increased accordingly. The following will introduce you to the above-mentioned iron ore beneficiation processes to help you better understand the iron ore separation process.

Applied material :

Hematite, Magnetite, Goethite, Siderite, Taconite, Limonite, Quartz, Calcite, Clay Minerals, Mica, Feldspar, Etc.

Working Flow

Iron Ore Beneficiation Plant process includes selection of effective grinding technologies, magnetic separation techniques for the Fe upgradation and finally to produce the desired density in the product in the form of concentrate slurry for pumping. This wet beneficiation plant for producing high-grade iron ore concentrate requires scrubber, screens, grinding mills, spiral classifiers, hydro-sizers / hydro-cyclones, magnetic separators, agitators, , filters and thickeners.

Free Scheme and estimate cost of Beneficiation plant can be sent to you now.

Placer gold mines and rock gold mines are often mined.

Gold ore mines have 4 types: placer gold mine, carlin-type gold mine, volcanic gold mine, rock gold mine, and iron cap gold mine.

1. Crushing: Use jaw crusher to crush the raw material into 0-25mm particles.

2. Grinding: Use ball mill to grind the particle materials into powder (0.074-2mm).

3. Gravity concentration: Use gold shaking table to separate the gold concentrate from the powder(0-2mm).

Gold ore mines have 4 types: placer gold mine, carlin-type gold mine, volcanic gold mine, rock gold mine, and iron cap gold mine.

1. Crushing: Use jaw crusher to crush the raw material into 0-25mm particles.

2. Grinding: Use ball mill to grind the particle materials into powder (0.074-2mm).

3. Gravity concentration: Use gold shaking table to separate the gold concentrate from the powder(0-2mm).

Product Features

1.Crushing & screening

A vibrating feeder is to evenly feed iron ore into jaw crusher and secondary cone crusher, then use vibrating screen to screened out to meet the particle size for grinding.

Machine list: hopper, vibrating feeder, jaw crusher, cone crusher or hammer crusher(optional)

Machine list: hopper, vibrating feeder, jaw crusher, cone crusher or hammer crusher(optional)

2.Grinding & Classifying

The ore has relatively high hardness and extremely fine particle size. It adopts two-stage grinding process, which is ball mill combined with a spiral classifier to achieve the required grinding fineness.

Machine list: electromagnetic vibrating feeder or similar, ball mill, sprial classifier

Machine list: electromagnetic vibrating feeder or similar, ball mill, sprial classifier

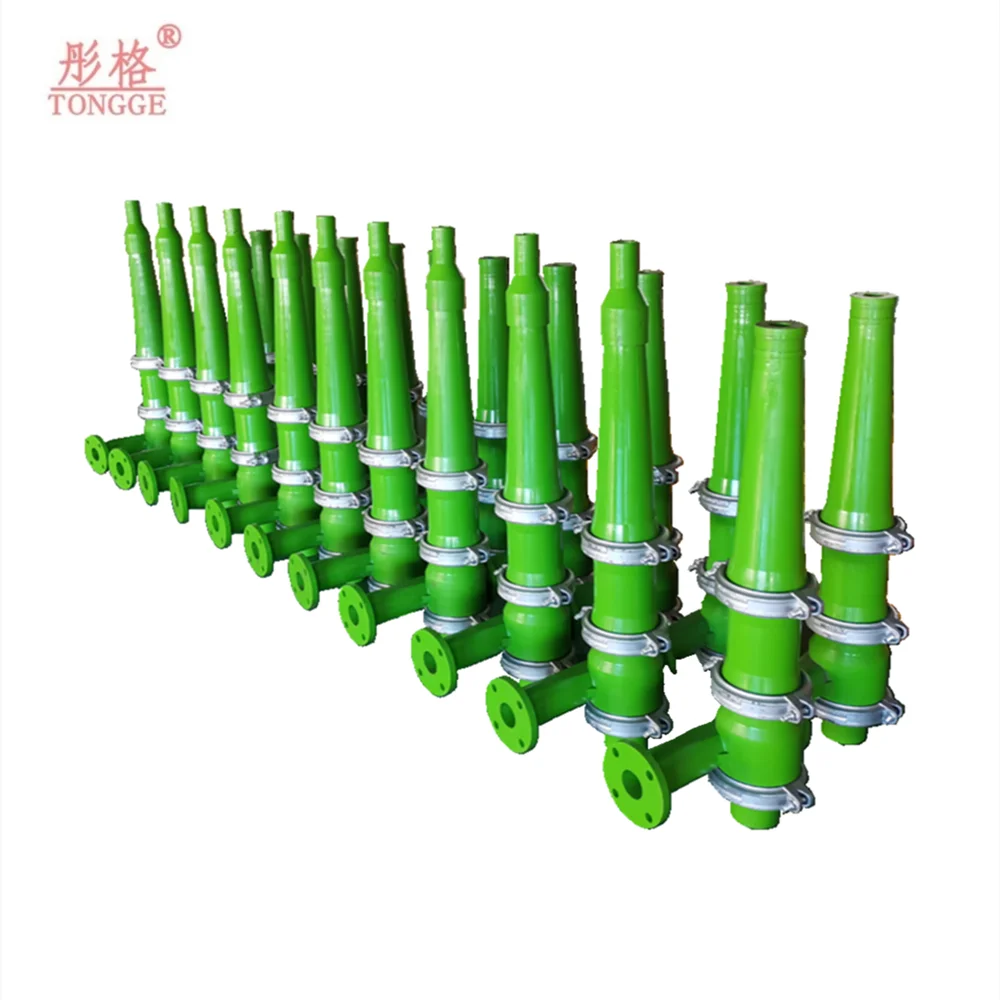

3.Magnetic Separation:

Separation generally adopts permanent magnet drum type magnetic separator.Most magnetite beneficiation plants often adopt coarse-grained dry magnetic separation tailings. For the ultra-lean magnetite ore with a grade below 20.00%, the ultra-fine crushing-wet magnetic separation tailing process can be used before entering the mill. That is to say, the ore is finely crushed to below 5mm-3mm, and then wet magnetic separation and tailing are carried out with a permanent magnetic field magnetic separator.

Machine list: strong magnetic separator,weak magnetci separator, high efficiency screen etc.

Machine list: strong magnetic separator,weak magnetci separator, high efficiency screen etc.

4. Tailings treatment:

After obtaining the magnetite concentrate, the tailings must be concentrated and dehydrated. After passing through the dryer, the dried mineral products can be obtained.

Machine list: tailing recovery machine, vacuum filter, rotary dryer etc is optional.

Machine list: tailing recovery machine, vacuum filter, rotary dryer etc is optional.

Equipment | Function |

Jaw crusher | Crush the material to below 300 mm for the first-stage crushing. |

Cone crusher | Crush the material to below 20 mm for the second-stage crushing. |

Ball mill | Crush and grind materials of 20 mm to 0.074-0.4 mm. |

Spiral classifier | According to the different specific gravity of the materials, the ore mixture is washed and classified. |

Magnetic separator | Magnetic material is separated from other materials by magnetic and mechanical forces. |

Flotation machine | Add reagents to separate the required minerals from other substances. |

High-efficiency concentrator | Concentrate the pulp. |

River sand dryer | Dry the material. |

Our Advantages

1. Higher dressing index and low dressing cost.

2. The whole space design is very reasonable. Strong handling capacity.

3. The level of iron ore concentrates is improved by 60%. The whole economic benefits are quite favorable.

2. The whole space design is very reasonable. Strong handling capacity.

3. The level of iron ore concentrates is improved by 60%. The whole economic benefits are quite favorable.

Why Choose Us

Provide the most scientific solution

According to the environment, geology, climate, we’ll design scientific and reasonable production line for customers.

Our recommended solution will strictly comply with local environmental protection standards, and provide you with green iron ore processing machines and related equipment.

Our recommended solution will strictly comply with local environmental protection standards, and provide you with green iron ore processing machines and related equipment.

Customer Cases

Packaging Details: We will make different packaging according to different machine sizes. Standard international export packing, container, wooden box.

Delivery Time: We will customize according to the actual needs of customers. Senior designers start to design the plan. After receiving the deposit, we will complete the delivery within 20 to 30 working days.

Company Profile

ZOOMJO is a large-scale enterprise that mainly produces heavy mining machinery and integrates scientific research, production and sales. It mainly produces various large and medium-sized crushing equipment, sand making equipment, drying and calcining equipment, mineral processing equipment and other series of products.

ZOOMJO has developed steadily from its establishment to the present with its technical strength, and has grown stronger day by day, and has gathered a large number of high-level management and scientific research personnel. Our company covers an area of 50,000 square meters, and another 10,000 square meters of modern office space, R&D center and sales center. The company has more than 500 employees, including more than 20 intermediate technicians. With strong technical strength, scientific management system and high product quality, ZOOMJO will rapidly grow into an important production and export base of mining machinery.

FAQ

1. How is the quality of your products?

Our products are manufactured strictly according to national and international standard, and we take a test on every grinder before delivery.

2. Is the price of products reliable?

Yes, we are manufacturer and we have the strength to give you the lowest price compared with other dealers. However, we have the policy that "According to the quantity order, we will offer the lowest price as possible with our utterly honest attitude towards business ".

3. Will you help with installation and staff training?

Yes, we can send our engineers to your place to guide the installation and train your workers if needed, but the buyer should bear our technician’s round tickets, accommodation, and food.

4. Service and Payment Terms?

a. We usually accept T/T, L/C, but other terms also workable.

b. We take pictures of finished products before delivery.

Our products are manufactured strictly according to national and international standard, and we take a test on every grinder before delivery.

2. Is the price of products reliable?

Yes, we are manufacturer and we have the strength to give you the lowest price compared with other dealers. However, we have the policy that "According to the quantity order, we will offer the lowest price as possible with our utterly honest attitude towards business ".

3. Will you help with installation and staff training?

Yes, we can send our engineers to your place to guide the installation and train your workers if needed, but the buyer should bear our technician’s round tickets, accommodation, and food.

4. Service and Payment Terms?

a. We usually accept T/T, L/C, but other terms also workable.

b. We take pictures of finished products before delivery.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices