non fried puffed snack extrusion processing line korean puffed rice snack making and packing machine

- Category: >>>

- Supplier: Jinan Dayi Extrusion Machinery Co. Ltd.Jinan Ltd.

Share on (1600937430405):

Product Overview

Description

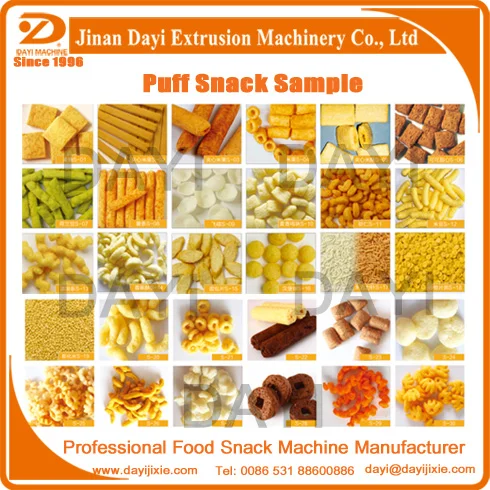

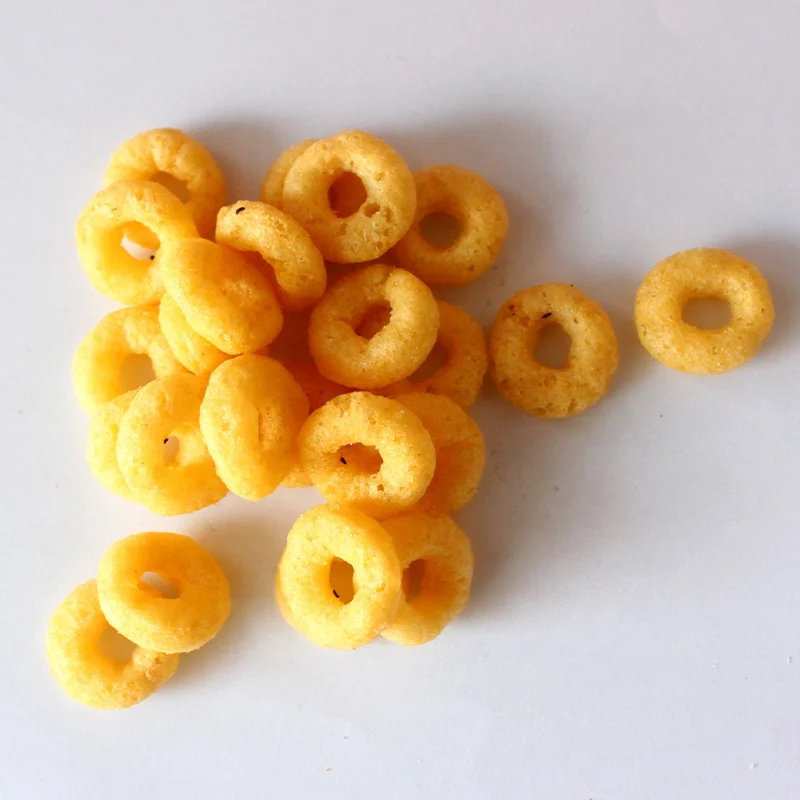

Quality corn puff sticks snack chips food machine

Direct puff snack process line adopts advanced share exrtusion technology, which can extrude products with different textures and tastes out of Double-Screw Extruder at the same time. It can produce a variety of direct puff snack food which are popular in the world market, such as fragrant chicken, core-filling rolls,etc. It can also producenutritional powder,grain gruel and many other snacks by changing different moulds and assistants equipments. This automatic process line is of leading leve for its superior characters "Normal materials, convenient operation and maintenance, lower power consumption, higher output.

Model | SLG65-C | SLG70-C | SLG85-A |

Installed Power | 44kw | 57kw | 116kw |

Power Consumption | 31kw | 45kw | 90kw |

Capacity | 100~150kg/h | 200~250kg/h | 400~500kg/h |

Dimension | 18000*1200*2000 | 23500*1800*2600mm | 25000*2100*3000mm |

1) Direct transmission between motor and gear box,reducing energy consumption.

2) Feeding,main driving device, and rotary cutting device adopt inverter to adjust the speed with more powerful drive, stable running, and low consumption.

3) Screw is made of alloy steel with long life.Segmental assembled screws are applied tomore kinds of materials and products

4) Automatic lubrication system can lower down power consumption and prolong the life.

5) Double screws feed equal materials forcibly.

6) Hanging mould and knives seat and bearing knife adjusting system can adjust the kniver exactly and swiftly.

Main Features

Name: Flour Mixer Ⅰ

Model: BF-Ⅰ

Brand: Jinan DAYI EXTRUSION MACHIENRY CO.,LTD

Capacity: 25kg/batch

Standard Voltage:220V/50Hz,380V/50Hz,440V/50Hz,etc

Power:3kw

Applied to mix up raw materials equally.

Three-Layer Dryer

Model: DKX

Brand: Jinan DAYI EXTRUSION MACHIENRY CO.,LTD

Installed Power:220V/50Hz,380V/50Hz 440V/50Hz,etc

Capacity:100~150kg/h,200-250kg/h

Suitable to dry non-fried extrusion snacks, nutritional powder, bread crumb, pet food, textured vegetarian protein, etc.

Multi-functional Shaper

Model: CXD-I

Brand: Jinan DAYI EXTRUSION MACHIENRY CO.,LTD

Voltage:220V/50Hz,380V/50Hz,etc

This machine is an auxiliary equipment for a twin screw expansion testing machine, which trims and cuts the food blanks extruded from the main machine.

Model:PY-PG-PF

Brand: Jinan DAYI EXTRUSION MACHIENRY CO.,LTD

Capacity: 100~200kg/h

Driving Power:1.86kw

Applied to coat non-fried extrusion food with materials equally such as chocolate,sugar,salt, and oil, etc.

A1: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q2: What is your terms of delivery?

A2: EXW, FOB, CFR, CIF.

Q3: How about your delivery time?

A3: Generally, most of items we keep stock for all season . it will take 7 to 10 days after receiving your advance paymentif we didn't have stock ,The delivery time depends on the items and the quantity of your order. Normaly 30 to 60days.

Q4: Do you inspect all your goods before delivery?

A5: Yes, we have 100% test before delivery

2) Feeding,main driving device, and rotary cutting device adopt inverter to adjust the speed with more powerful drive, stable running, and low consumption.

3) Screw is made of alloy steel with long life.Segmental assembled screws are applied tomore kinds of materials and products.

4) Automatic lubrication system can lower down power consumption and prolong the life.

5) Double screws feed equal materials forcibly.

6) Hanging mould and knives seat and bearing knife adjusting system can adjust the kniver exactly and swiftly.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices