explosive welding alcu bimetal clad explosive bonding metal strip explosive alloys plate

- Category: >>>

- Supplier: Shanghai Nansen Industry Co. Ltd.

Share on (1600943836895):

Product Overview

Description

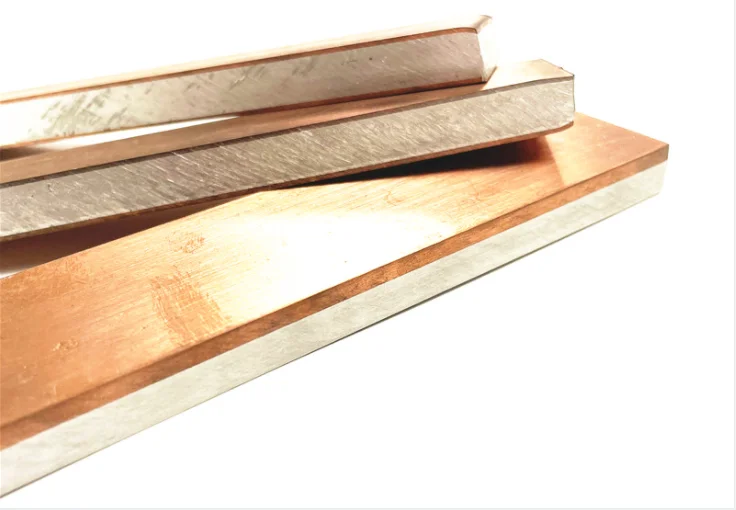

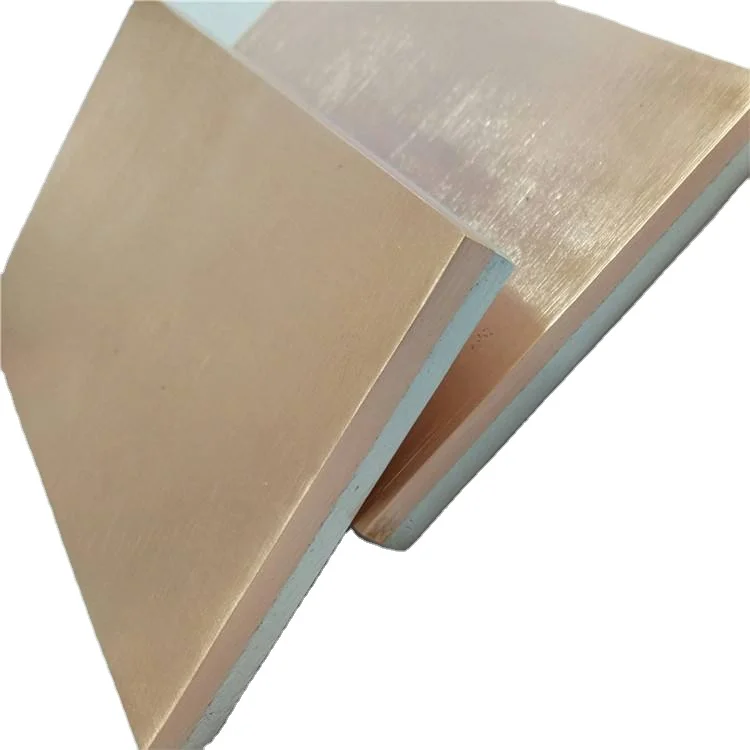

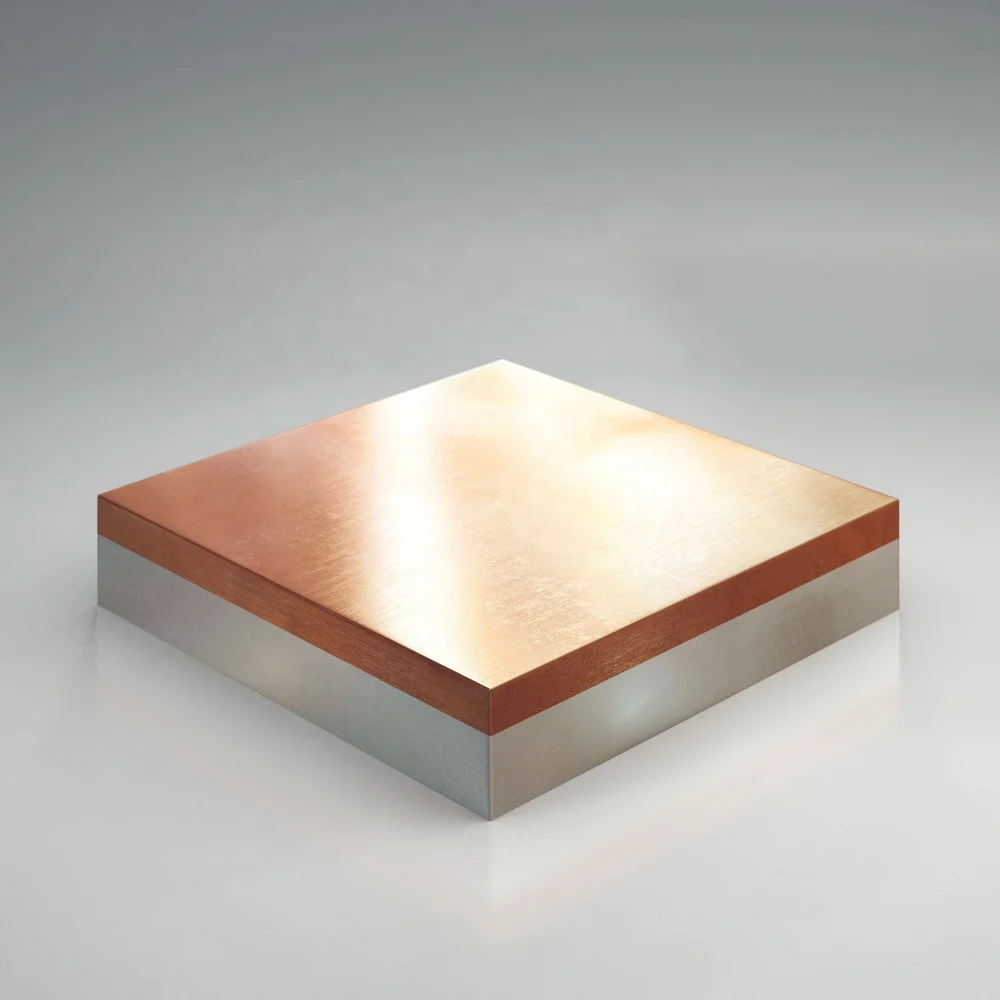

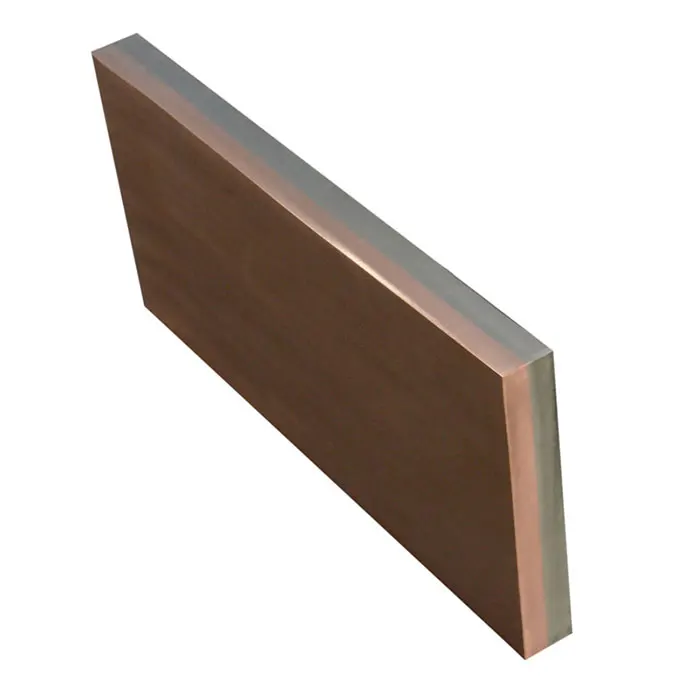

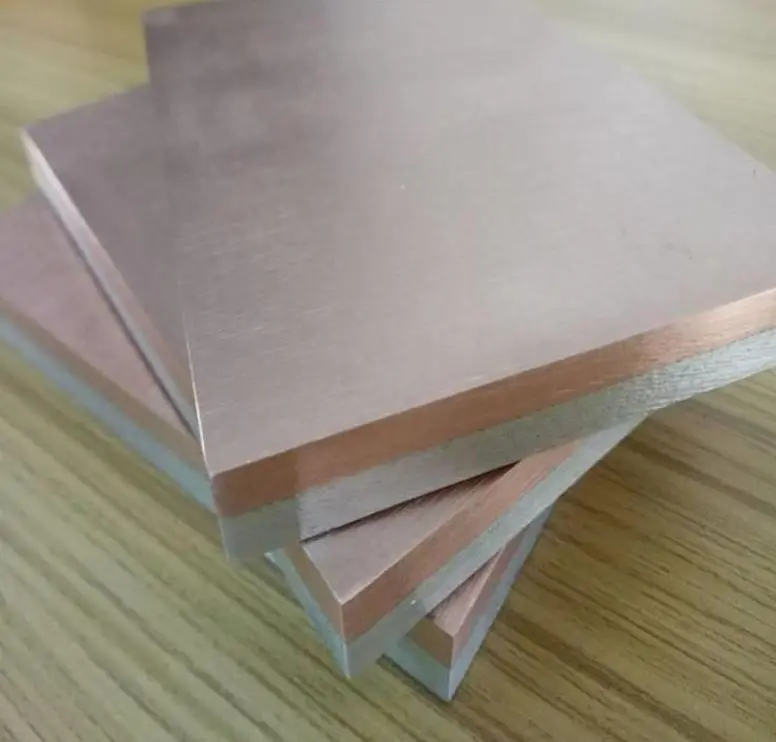

explosive welding alcu bimetal clad explosive bonding metal strip Explosive alloys plate

Explosive Welding Process Bimetal Plate:

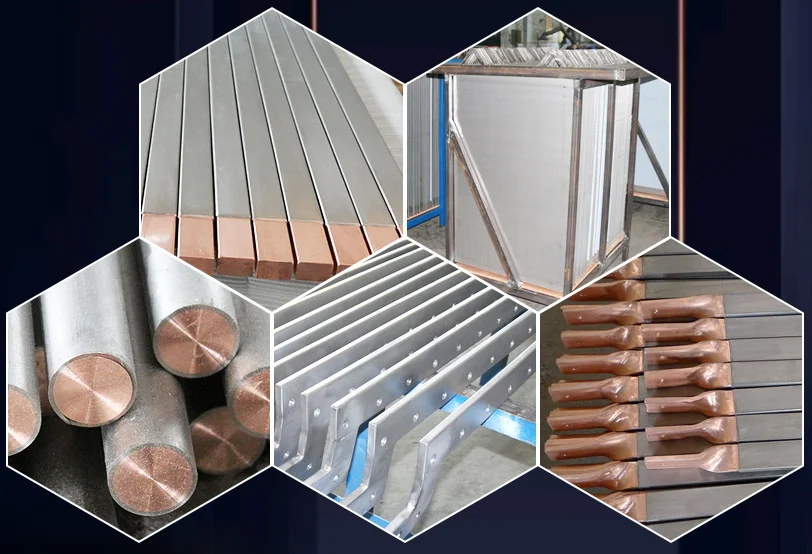

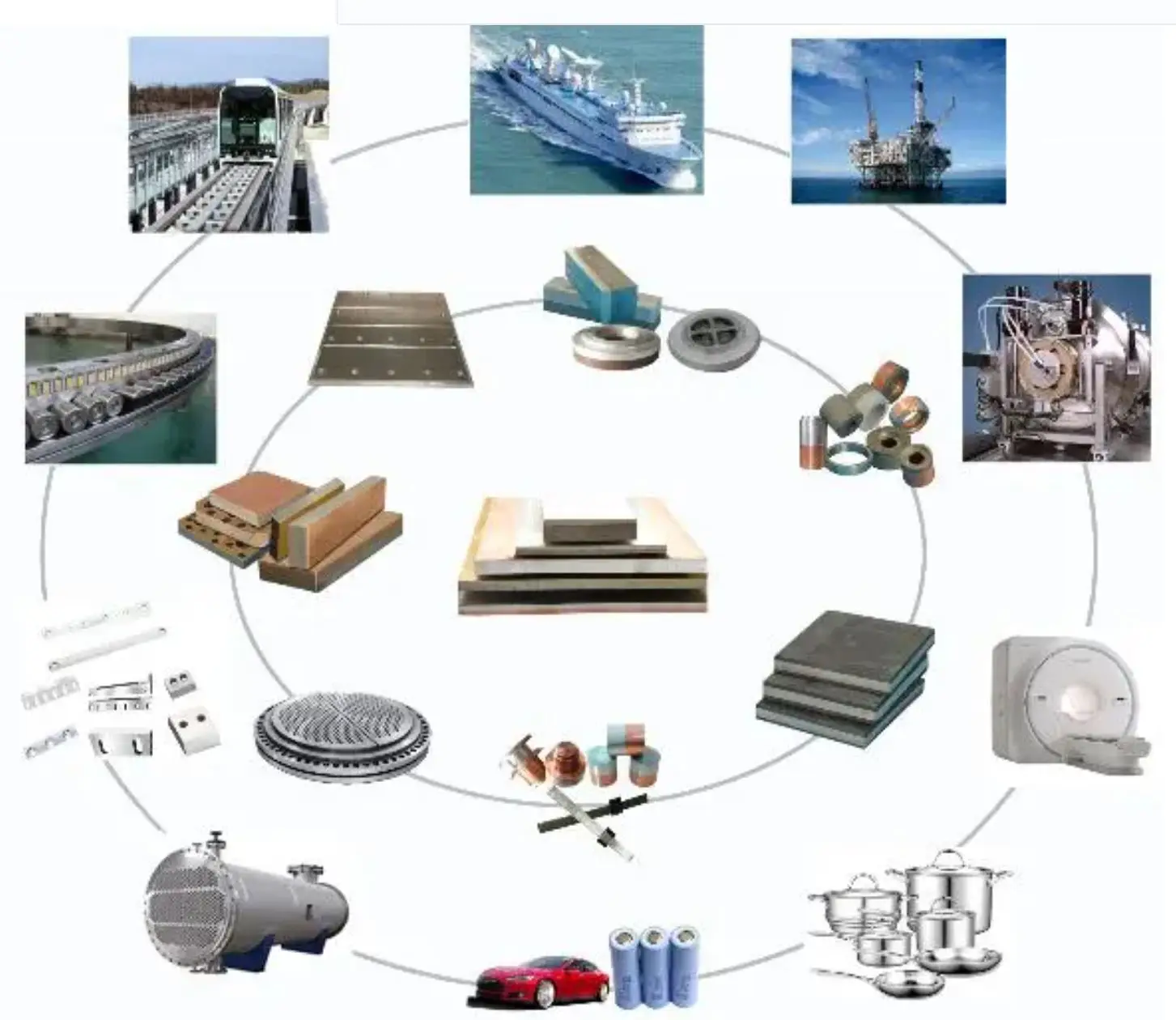

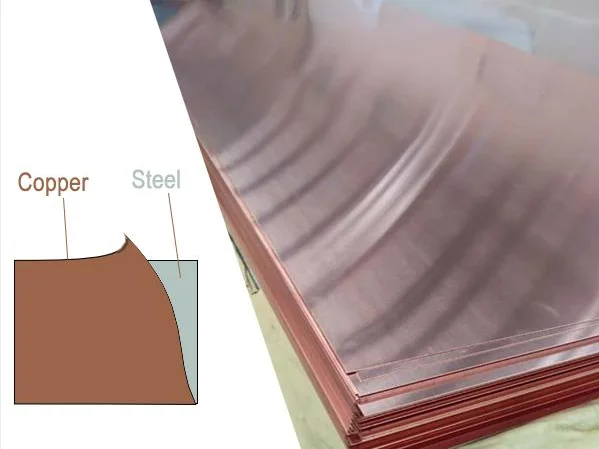

The copper clad steel sheet new material also has the advantages of both copper and steel materials. This material has high advantages in terms of electrical conductivity, welding, and corrosion resistance, and it has a high degree of incorporation of steel properties. The strength is an integrated functional material, which has the advantage that a single copper and steel cannot be compared. Copper clad steel plate is widely used and can be used in heating, heat- exchange equipment production, electronics and electrical fields, metallurgy, military industry, machinery, transportation and other fields..

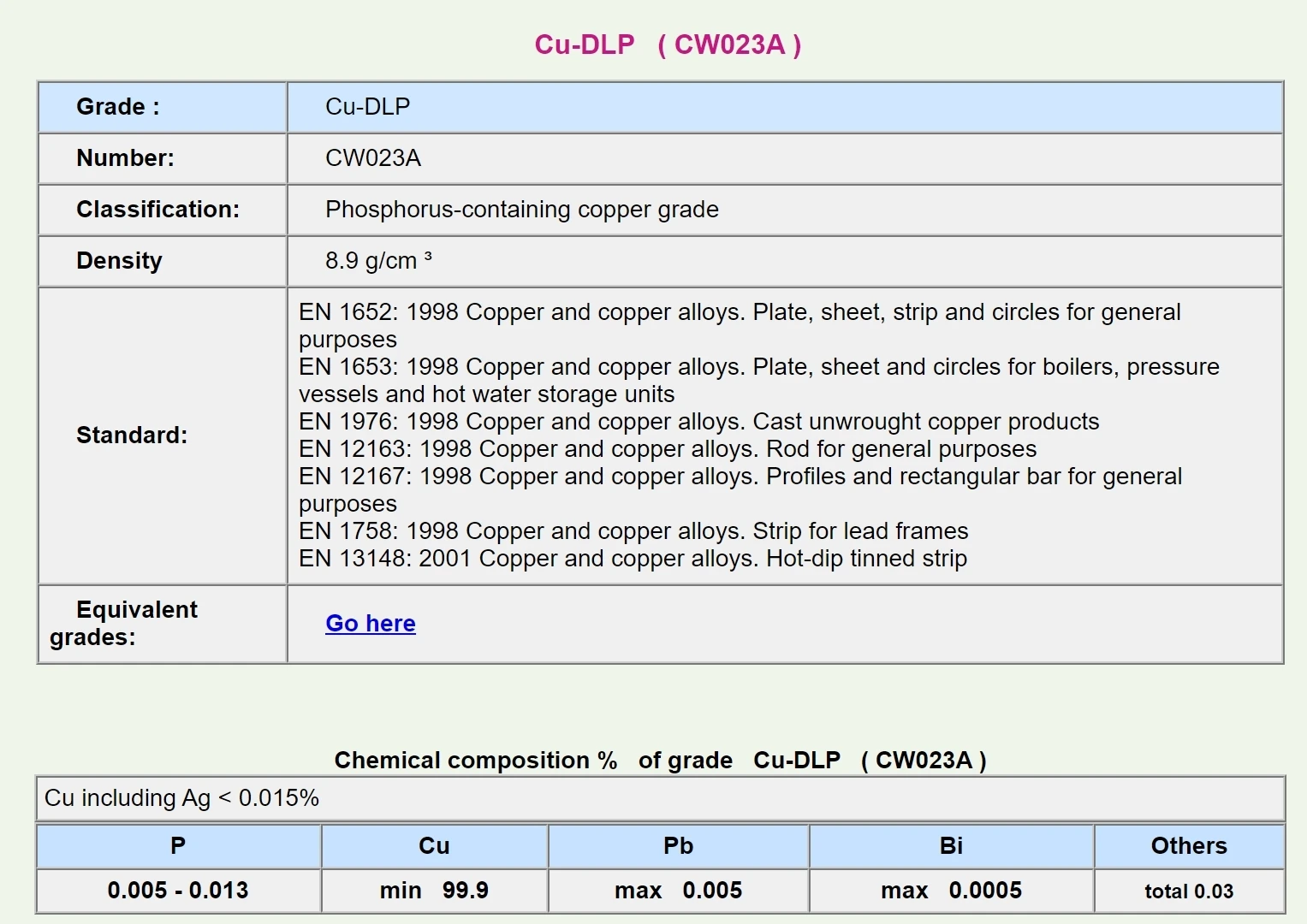

Raw material is : Materials: AISI 304/AISI 321 ( China standard is : Stainless steel alloy 304 ) + Cu-DLP EN- CW023A ( China Standard is : T2 )

- COMMONLY-USED MATERIAL COMBINATIONS :

- Cladding Material :304 (L),310S,316 (L),321,1Cr13,Ta2

Notes: Various combinations with different materials can be manufactured according to clients' request.

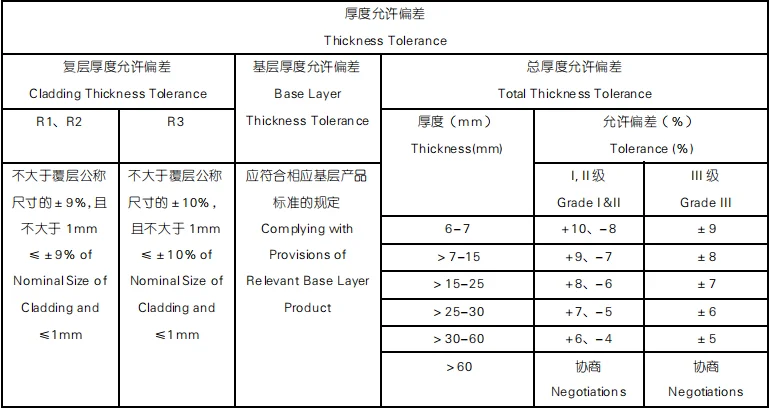

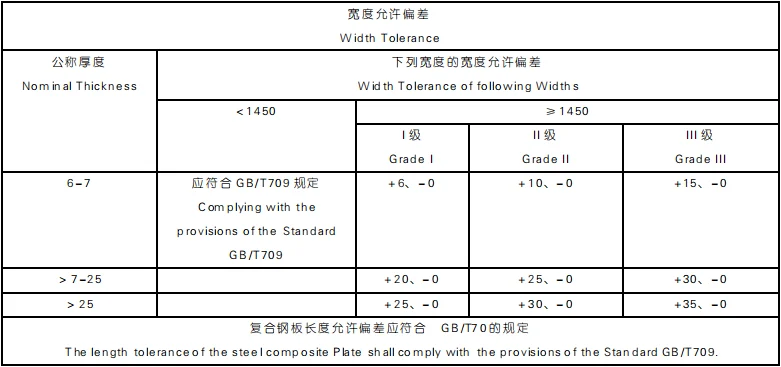

- Executive Standards :

Shanghai Nansen Industry Co., Ltd. will provide you with better products, more favorable prices, and better services.

Shanghai Nansen Industry Co., Ltd. is a professional company integrating the processing and sales of stainless steel products, metal clad panels (stainless steel clad panels, titanium steel clad panels, nickel steel clad panels) and other metal products. We are distributors of well-known domestic and foreign manufacturers such as Taiyuan Iron and Steel, Baosteel, Zhangpu, Jiugang, Dongfang Special Steel, Krupp of Germany, Outokumpu of Finland, and Columbus of South Africa.

Nansen's products include rare metal nickel alloys, imported and domestic stainless steel coils, medium-thick plates, stainless steel forgings, stainless steel rods, seamless pipes, welded pipes, embossed plates, 8K plates, and frosted plates. Nickel alloy: 800 (NO8800), 800H (NO8810), 825 (NO8825), 600 (NO6600), 625 (NO6625), 400 (NO4400) Steel material: 430, 201, 202, 301, 304, 304L, 309, 309S, 310, 310S, 2205, 317L.

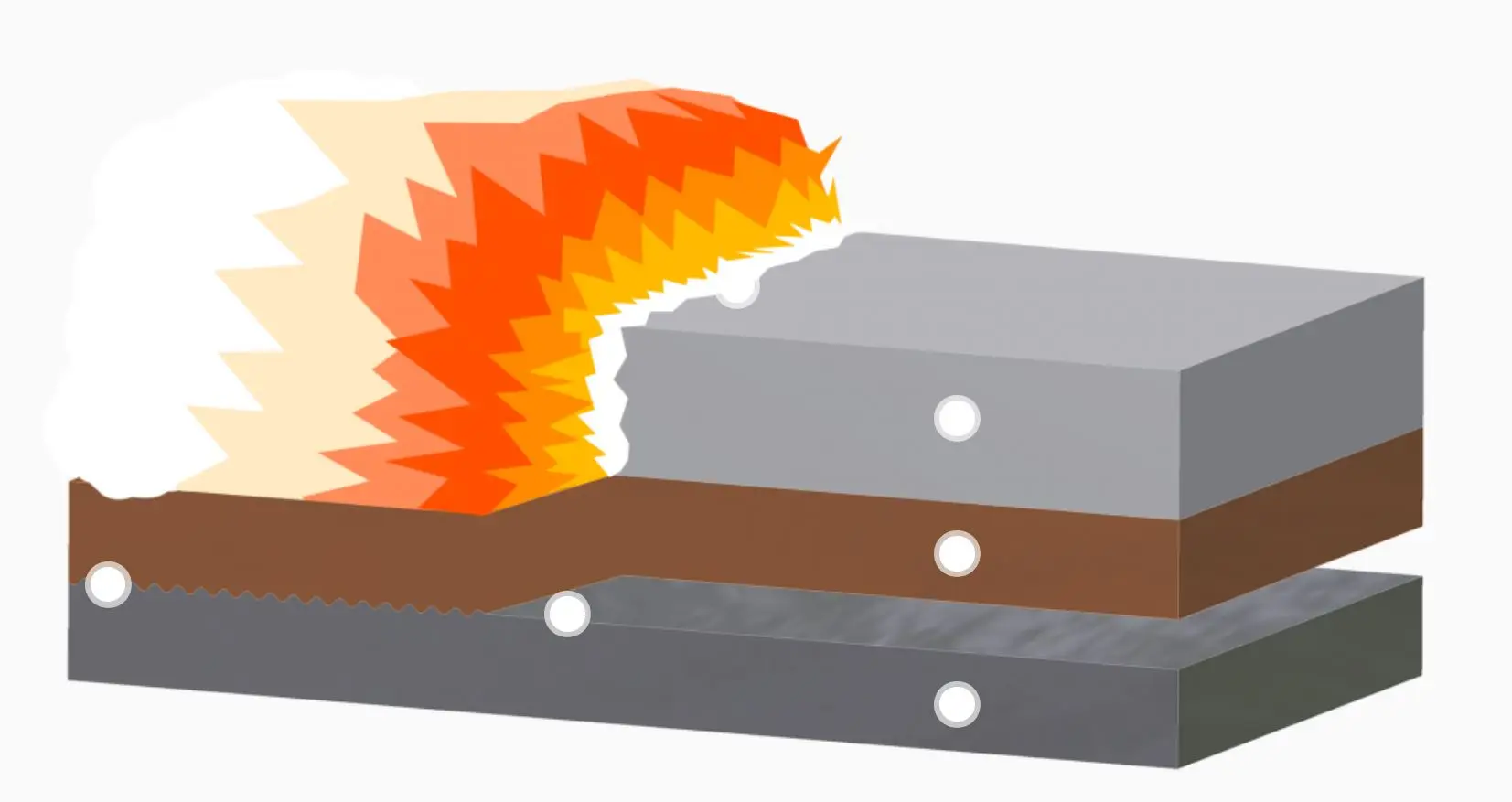

Explosive welding bimetal plates find a wide range of applications in various industries due to their unique ability to combine the desirable properties of two different materials. The explosive welding process creates a strong metallurgical bond between the two materials, allowing for improved performance and cost-effective solutions in demanding applications .

- Required is : vacuum tight, part will be subject to 100% radiographic inspection.

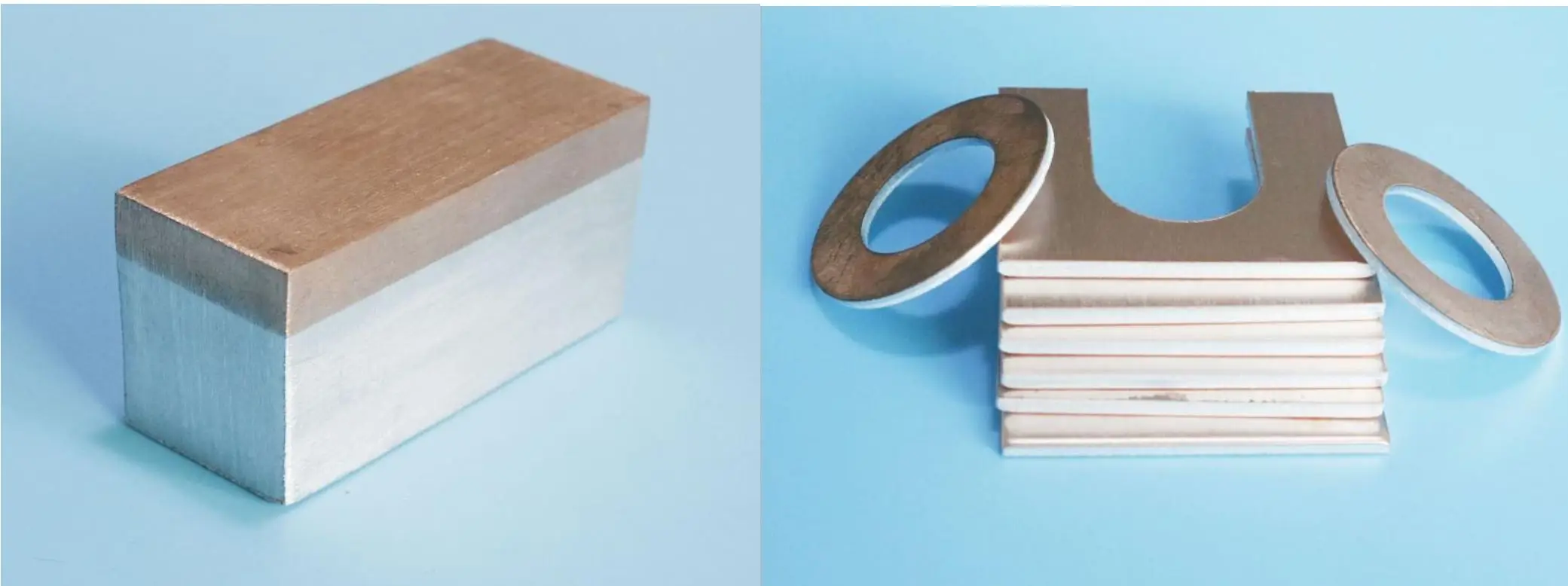

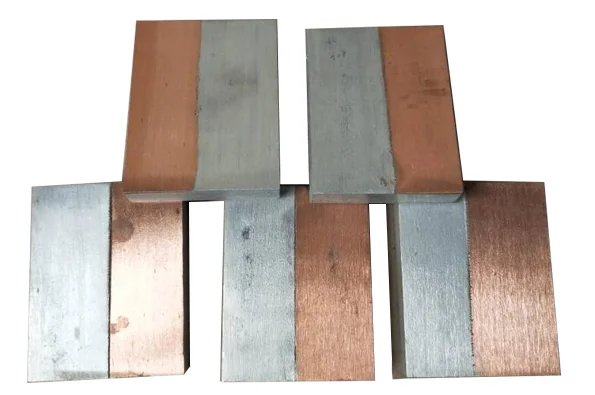

- Processing is : : Bimetallic Explosive Welding Clad Technology

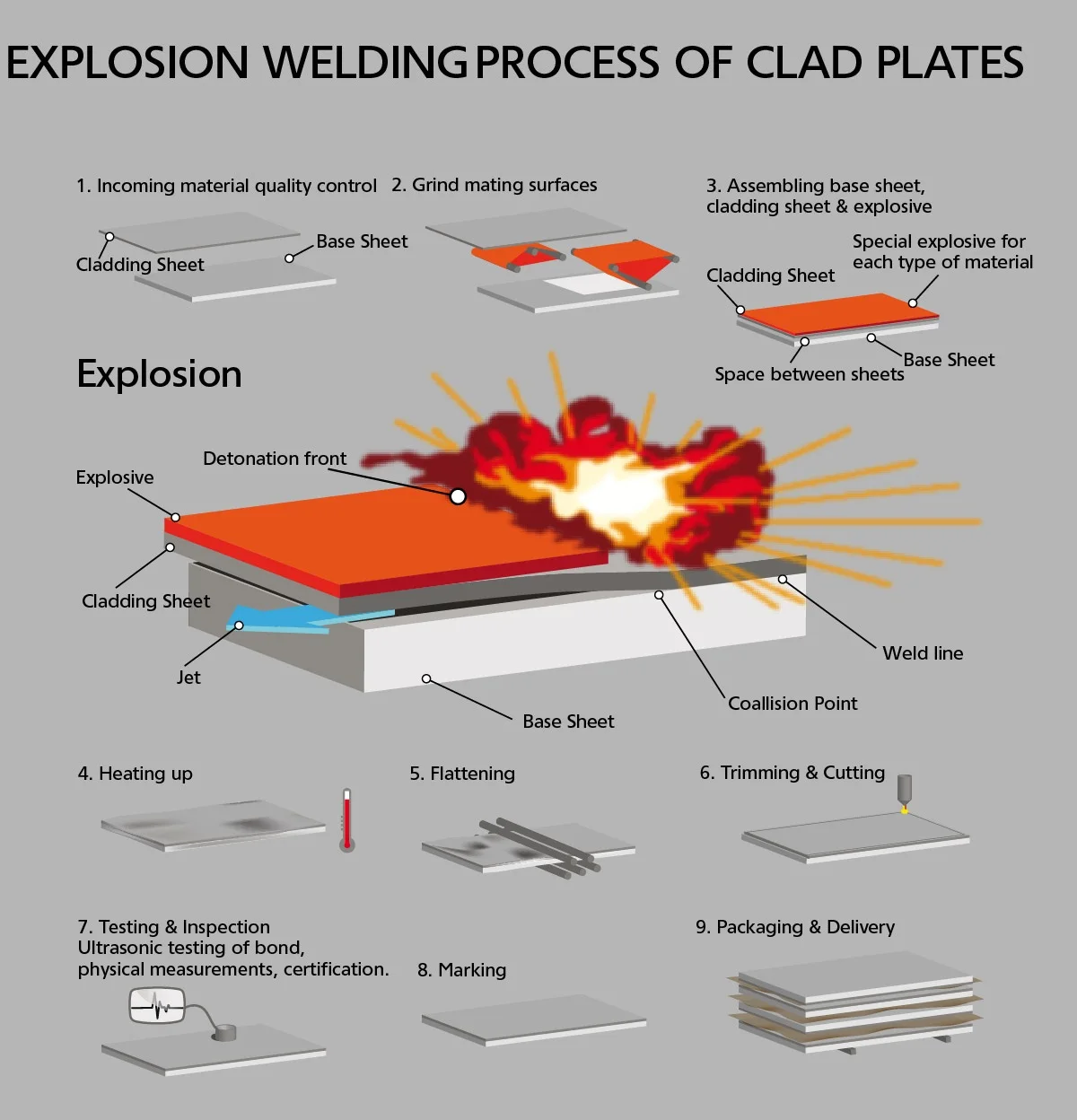

-Explosive welding, also known as explosive bonding or explosion welding, is a specialized and highly effective process used to join two dissimilar metals or materials by utilizing explosive energy to create a metallurgical bond between them. This process is primarily used in industries such as aerospace, defense, shipbuilding, and oil and gas, where it's essential to combine materials with distinct properties to achieve optimal performance.

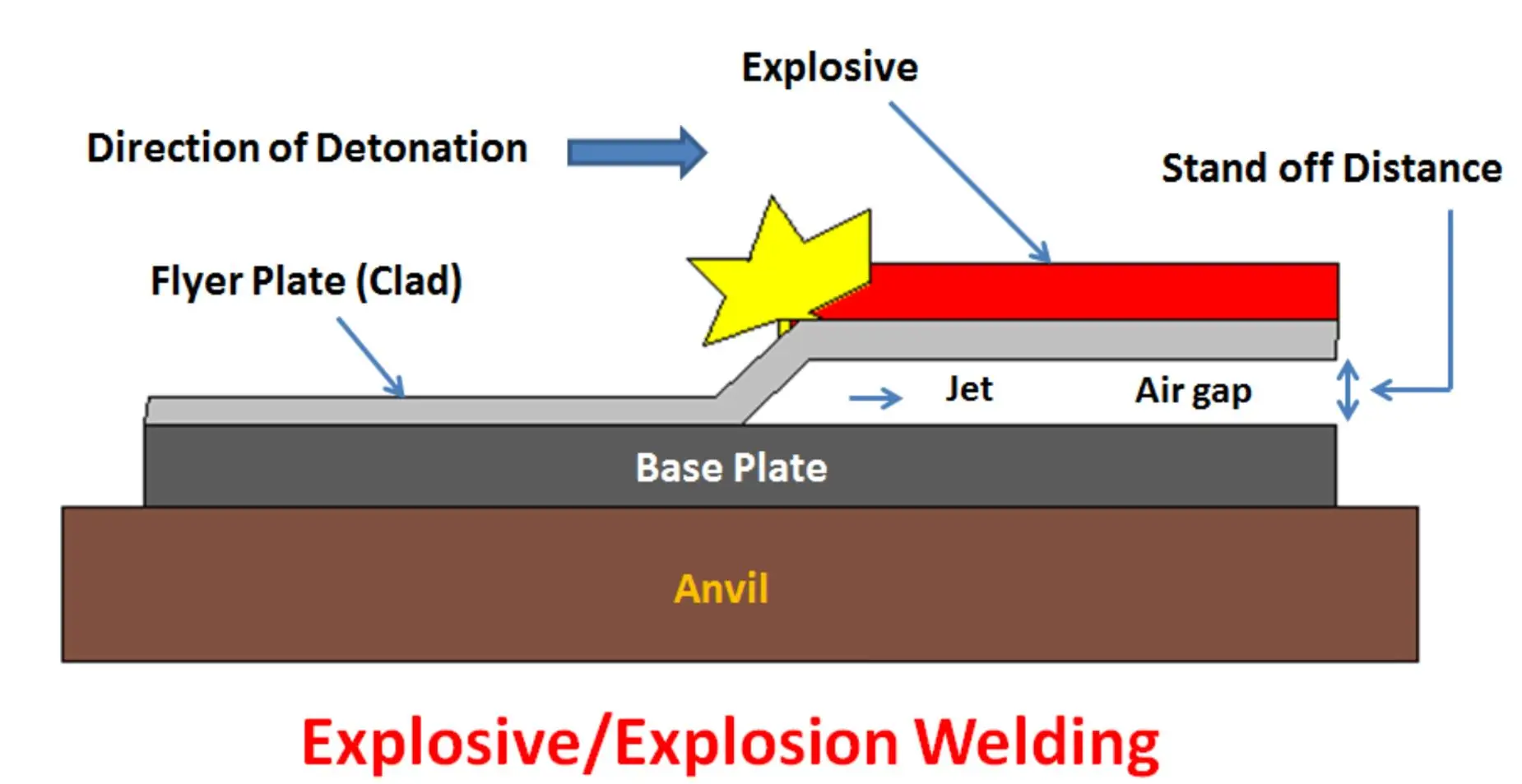

- Material Selection: Two materials with different properties are chosen for welding. These materials can include metals, alloys, and composites. Typically, one of the materials is considered the "base" material, while the other is the "flyer" material.

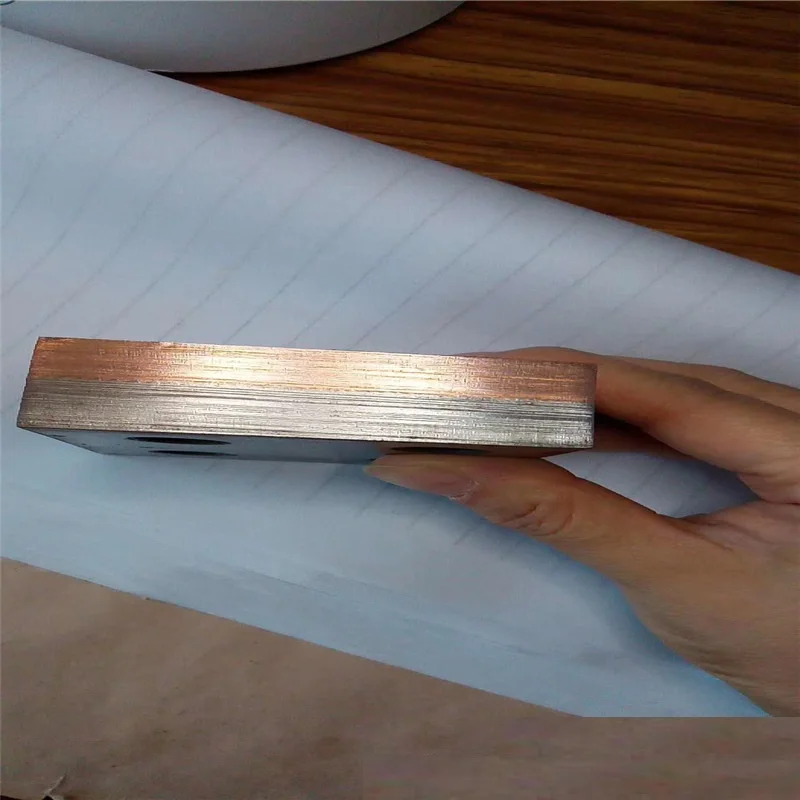

- Surface Preparation: The surfaces of both materials are thoroughly cleaned and prepared. Any contaminants or oxides are removed to ensure a clean interface between the two materials.

- Assembly: The two materials are assembled in a specific configuration, with the flyer material placed on top of the base material. The materials are typically flat sheets, but explosive welding can also be used for joining cylindrical or other shapes.

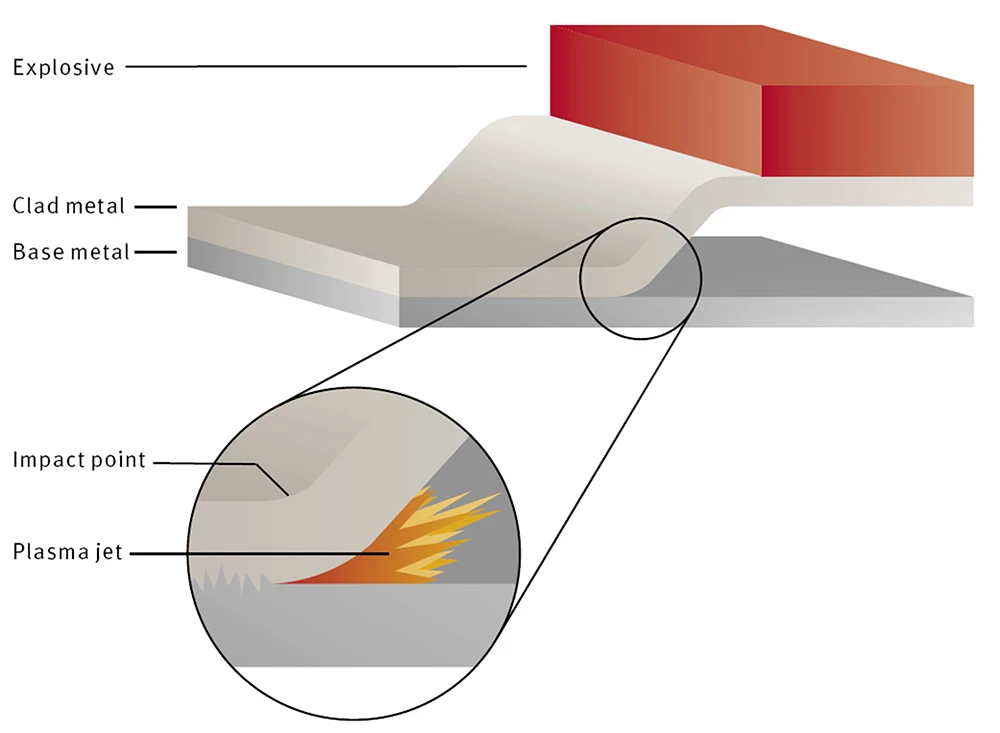

- Explosive Setup: An explosive material, often in the form of a thin sheet or a liner, is placed on top of the flyer material. The explosive material is carefully shaped and distributed to ensure an even distribution of the explosive energy upon detonation.

- Detonation: A controlled explosion is initiated at a precise location on the explosive material. The shock wave generated by the explosion accelerates the flyer material towards the base material at a high velocity.

- Impact and Bonding: The flyer material impacts the base material with significant force and velocity, causing the surfaces to deform and come into contact. This high-pressure impact generates enough heat and pressure to remove surface contaminants, create a metallurgical bond, and force the materials to merge at the atomic level.

- Bond Formation: As a result of the explosive energy and subsequent plastic deformation, the materials undergo localized melting and solid-state bonding, creating a strong metallurgical bond. The bonding process occurs in milliseconds.

- Post-Welding Processing: After the explosion, the welded assembly may undergo post-processing steps such as heat treatment, machining, or further shaping to achieve the desired final product.

Q: Why choose NANSEN?

A: Professionally provide package solution for customers from over 20 countries.

Q: What can we expect from NANSEN?

A: Superior quality, reasonable price, exclusive service, and good after sale guarantee.

Q: Can you do customized design and size?

A: Yes, ODM &OEM are available.

Q: Can I have some samples?

A: Of course, samples are (1-3 pcs) or 2-3 kg

Q: When can we get samples and goods?

A: Samples will be sent immediately if have stock, make new will take 2-3days.

Goods will be shipped within 30days after order confirmed.

Q: What's kind of payment can you offer?

A: We can offer L/C, T/T, Western Union, Paypal etc.

Ms.Monica

Shanghai Nansen Industry Co., Ltd.

Address: Pudong District, Shanghai, China.

Tel: 86-21-2024 9001

Wechat /what'app : 0086-18202112981

Email: sales at nansencn. com

Website: www.nansen-bimetal.com

We Recommend

New Arrivals

New products from manufacturers at wholesale prices