HRC45 Ball Nose End Mill 2 Flute Straight Shank End Mill CNC Tungsten Carbide Milling Cutter 45 Degree Carbide Milling Tools

- Category: >>>

- Supplier: Foshan Yunsheng Metal Technology Co. Ltd.

Share on (1600953942602):

Product Overview

Description

Product Description

High Feed Milling Cutter 2 flutes Carbide Ball Nose End Mill.

【Top Quality】:The round tip end mill with 2 cutting edges is made of HRC45 carbide with AlTiN coating, is very durable, wear-resistant and offers high cutting performance.

【AlTiN coating】: Titanium aluminum nitride (AlTiN) coating lubricates the end mill for stability at high temperatures and superior wear resistance at high cutting speeds and provides better heat resistance than TiAlN, TiN or TiCN coatings

【Wide application】: Nano carbide ball cutter, ideal for carbon steel, alloy steel, cast iron etc

【End Mill Set R0.5-R10.0mm】This 2-edge ball mill cutter contains many sizes of end mills. You no longer have to worry about waste and can meet your different needs.

【Satisfaction】Vinson strives to provide all customers with high-quality products. If you have any problems, just contact us and our customer service team will solve your problems as soon as possible.

【AlTiN coating】: Titanium aluminum nitride (AlTiN) coating lubricates the end mill for stability at high temperatures and superior wear resistance at high cutting speeds and provides better heat resistance than TiAlN, TiN or TiCN coatings

【Wide application】: Nano carbide ball cutter, ideal for carbon steel, alloy steel, cast iron etc

【End Mill Set R0.5-R10.0mm】This 2-edge ball mill cutter contains many sizes of end mills. You no longer have to worry about waste and can meet your different needs.

【Satisfaction】Vinson strives to provide all customers with high-quality products. If you have any problems, just contact us and our customer service team will solve your problems as soon as possible.

Specification

item | value |

Warranty | other |

Customized support | OEM, ODM |

Place of Origin | China |

Guangdong | |

Brand Name | OTHER |

Usage | External Turning Tool |

Hardness | hrc45 |

Coating | AlTiN |

Product name | HRC45 2 Flute Ball Nose End Mill |

Application | Milling Cutter |

Applicable materials | carbon steel, alloy steel, cast iron |

Applicable machines | advertising engraving machine, woodworking engraving machine, etc. |

Suggested speed | 18000~2000 rpm |

Blade radius | 0.5-10mm |

Blade Length | 2-50mm |

Shank Diameter | 3-12mm |

Overall Length | 50-150mm |

Production material | overall tungsten steel |

Product Paramenters

Customer Service

Product packaging

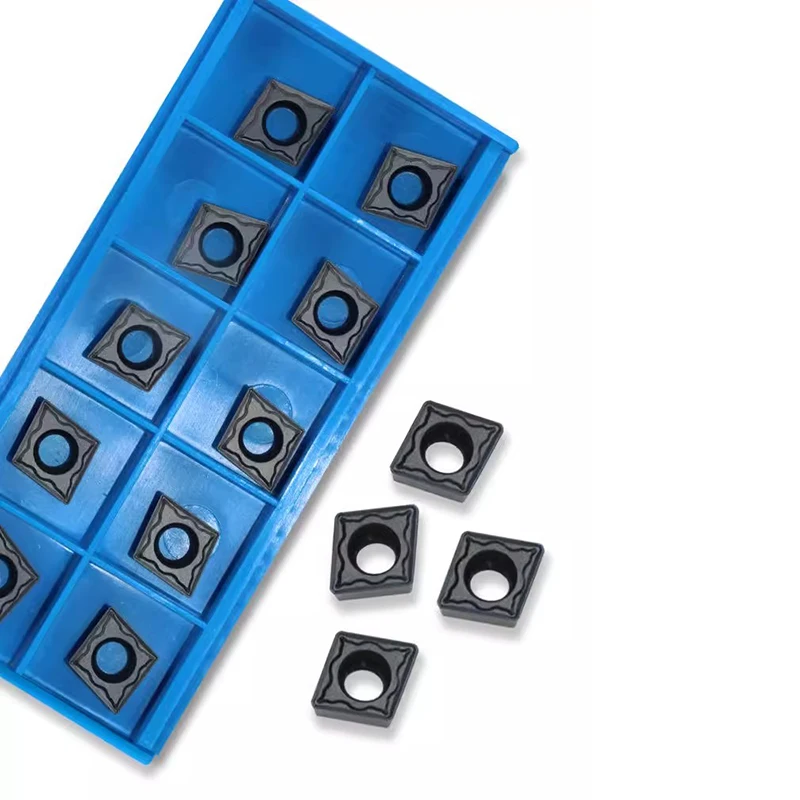

1. Put the gun drill in a plastic box specially for end mill

2. Add cushioning padding in the plastic box

3. Wrap the sponge or other cushioning material in the plastic box with the end mill

4. Packed in carton or wooden box for shipping

2. Add cushioning padding in the plastic box

3. Wrap the sponge or other cushioning material in the plastic box with the end mill

4. Packed in carton or wooden box for shipping

Company Profile

Yunsheng Metal Technology Co., Ltd. is an enterprise specializing in deep hole tool manufacturing and large and complex deep hole machining. Since 2006, we have established a firm foothold in the domestic market, and have won many customers in Southeast Asia, the United States and other places. The company has also introduced foreign advanced technology and equipment to create a scientific research team that pursues excellence and continuous innovation, dedicated to Research and development, production and actual programming solutions for tool use in deep hole machining to improve the machining efficiency and service life of the tool.

We also import raw materials such as tungsten carbide tips and rods from Germany, which are mainly used for brazing single edge gun drills, brazing double edge gun drills, solid carbide gun drills, convertible (clamp) gun drills, inner row deep hole drills. Special tools for deep hole machining and accessories for deep hole machining can widely meet the needs of different customers.

We also import raw materials such as tungsten carbide tips and rods from Germany, which are mainly used for brazing single edge gun drills, brazing double edge gun drills, solid carbide gun drills, convertible (clamp) gun drills, inner row deep hole drills. Special tools for deep hole machining and accessories for deep hole machining can widely meet the needs of different customers.

Due to the complexity of large-scale deep hole machining, we are also equipped with a strong after-sales service team to provide one-stop service for deep hole tool machining solutions. We pursue the goal of excellence and hope to maintain close cooperation with machining centers all over the world.

Why Choose Us

1.Provide a high feed speed and improve the process efficiency.

2.Suitable for high hardness steel and can keep a long service life.

3. Material Solid carbide and whole forging processing make the turning tool with long service life, better wear-resistance, strength and rigidity, high working efficiency.

4. Unique surface treatment with good antiseptic property.

5. High seismic resistance performance, which can improve the surface finish degree of the workpiece.

6. Competitive price and fast delivery will save the time and cost.

2.Suitable for high hardness steel and can keep a long service life.

3. Material Solid carbide and whole forging processing make the turning tool with long service life, better wear-resistance, strength and rigidity, high working efficiency.

4. Unique surface treatment with good antiseptic property.

5. High seismic resistance performance, which can improve the surface finish degree of the workpiece.

6. Competitive price and fast delivery will save the time and cost.

FAQ

Q1: Are you trading company or manufacturer ?

A1: We are a company integrating industry and trade. The office is near the factory, so we can monitor the production of the factory. At the same time, we are also equipped with a strong after-sales service team to provide one-stop service for deep hole tool processing solutions.

Q2: How long is your delivery time?

A2: Generally it is 10-15 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q3: Do you provide samples ?

A3: Yes, we provide sample service, communicate with us about sample clearance to provide you with the best solution

Q4:Can you make the products as our requirement?

A4:We have more than 10 years' OEM experience. We supply products fo more than 100 parts factories.

Q5: What is your terms of payment ?

A5: Payment will be made by T/T and so on.Please contact us

A1: We are a company integrating industry and trade. The office is near the factory, so we can monitor the production of the factory. At the same time, we are also equipped with a strong after-sales service team to provide one-stop service for deep hole tool processing solutions.

Q2: How long is your delivery time?

A2: Generally it is 10-15 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q3: Do you provide samples ?

A3: Yes, we provide sample service, communicate with us about sample clearance to provide you with the best solution

Q4:Can you make the products as our requirement?

A4:We have more than 10 years' OEM experience. We supply products fo more than 100 parts factories.

Q5: What is your terms of payment ?

A5: Payment will be made by T/T and so on.Please contact us

Recommend Products

We Recommend

New Arrivals

New products from manufacturers at wholesale prices