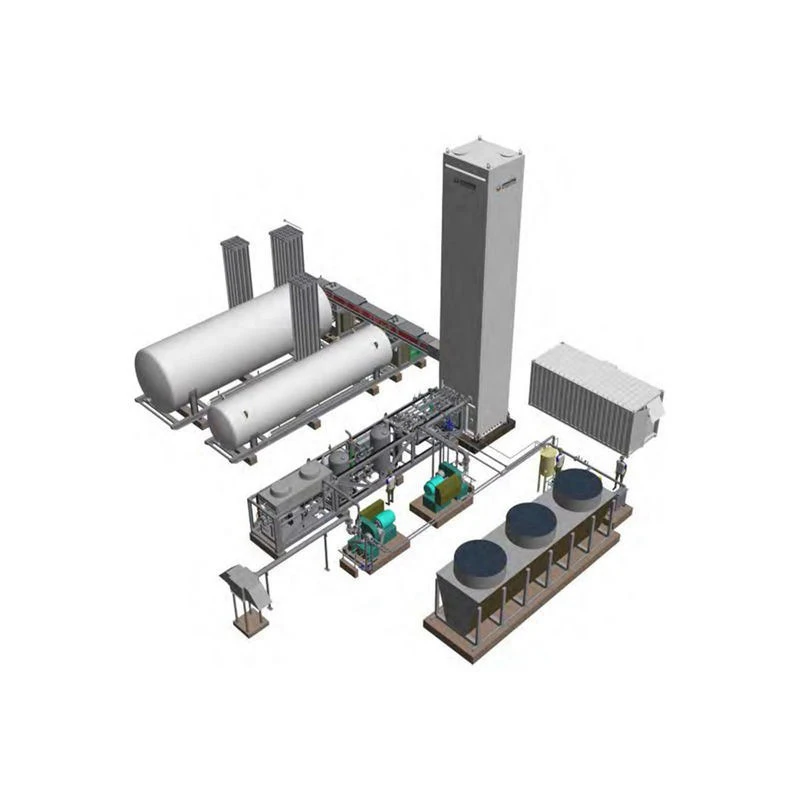

Nitrogen Gas Generation Equipment Oxygen Nitrogen Plant Booster Expanders Turbine Expander Liquefaction Lng Power Plant 99%

- Category: >>>

- Supplier: Shenzhen Longer Industry Co. Ltd.Shenzhen Ltd.

Share on (1600968394752):

Product Overview

Description

Oxygen Output | Oxygen purity | Power | Operation pressure | Operation Cycle |

50M3 | 99.999% | 440V/380V/220V/50HZ/customized | 1.2Mpa | 12Months |

80M3 | 99.999% | 440V/380V/220V/50HZ/customized | 1.2Mpa | 12Months |

100M3 | 99.999% | 440V/380V/220V/50HZ/customized | 1.2Mpa | 12Months |

180M3 | 99.999% | 440V/380V/220V/50HZ/customized | 1.2Mpa | 12Months |

300M3 | 99.999% | 440V/380V/220V/50HZ/customized | 1.2Mpa | 12Months |

(2)Produce high quality medical oxygen, completely accord with standard of medical oxygen, can sell to the hospital, can also ues for industrial .

(3)The whole equipment without base installation, stable running, simple operation, easy maintenance.

1.Main air compressor

Air compressor is manufactured by world famous brand with Flexible and convenient operation, stable operation and low energy consumption

(1) Freon/air heat exchanging pre-cooling system, the unit is stable and very easy to maintain, high & low pressure and overheat self-protection function to make sure the operation is safer and more reliable.

(2) Skid closed structure with little area occupation

3.Air purification system

(1) Remove dangerous impurities contained in the air before entering the cold box and brings complete safety for a long operating time without any necessary defrosting

(2) Use double layer system, very effectively protects the layer of the molecular sieve.

(3) High strength, large dynamic adsorption capacity, long service life.

4. Turbine expansion unit

(1) Adopt advanced design and processing software to achieve the best performance

NO | Main Part | Function |

1 | Air Compressor | The air compressor is sprayed-oil screw type compressor, box-body construction and main machine is imported from Germany. It has low noise and the main machine combines gas, lubrication, water, cooling and electrical instrument to one compact unit. The control system adopts PLC controller, touch-way panel provides the operation of all adjustment of parameter and critical running parameter. The liquid crystal display (with English text) has full protection function and thus has minimal operation supervision from a plant operator. |

2 | Pre Cooling System | It adopts a full-close imported compressor therefore refrigeration agent will never leak out. The high-efficient steam water separator and imported automatic drain water machine will ensure the outlet will not produce condensation. Refrigeration component is imported to support plant can run continuously (non stop) for 365 days a year. It is equipped with long-distance signal connecting point of air inlet temperature, long distance signal of start and stop machine and operating trouble indicator or signal thus it is convenient for user’s interlock supervision. The unit is box type body construction. The foundation is easy to install and construct. |

3 | Purifier | The unit is composed of two vessels: one is on heating while the other being regenerated. This ensures that the gas will be clean and purified to prolong the running period of rectifying (rectification) column. The system uses nitrogen to heat for regenerated and has automatic control for the temperature heat. |

4 | Turbine Expander | Turbine expander has the following advantages: 1.easy to install 2.less maintenance and easy to maintain 3.high efficient, runs and operate stable 4.has minimal cooling lost 5.Rectification Column |

5 | Rectification Column | It incorporates an aluminum fin type heat exchange. The aluminum increases the heat exchange’s affection and depresses the operation pressure. This process will produce less power consumption thus saving on electricity cost. The unit is equipped with an advanced digital instrument for the temperature, flow and liquid display. It has replaced the traditional meters. |

Q: Are you trading company or factory?

A: We are Air Separation Plant manufacturer, founded in 2003.Clients are very welcomed to

visit our factory

Q: What is the terms of payment?

A: T/T, L/C etc.Q: How long is your delivery time?A: It depends on your order

request, generally it is 45-120 working days

Q: What’s the order process?

A:1) Inquiry---provide us all clear requirements.

2)Quotation---official quotation form with all clear specifications.

3) Contract confirmation---provide correct contract details.

4)Payment terms--- T/T 30% in advanced, balanced before shipment.

5) Production---mass production g. Shipping--- by sea, air or courier. Detailed picture of package will be provided.

6) Installation and commissioning.

Q: Can you provide oversea service?

A: Yes,our engineers are available for over sea services and they have very rich experience for overseas installation

Q: How to get a prompt quotation?

A: When you send us inquiry, please kindly tell us the below technical information.

1) O2/N2 Production capacity:____Nm3/h

2) O2/N2 Purity: ____%

3) O2/N2 Discharge pressure: ____Bar

4) Local Voltages and Frequency: _____V/PH/HZ

5) Application or use for which industry.

We Recommend

Cryogenic air Separation Unit Gas with Two Columns Oxygen Nitrogen Producing Manufacturers

New Arrivals

New products from manufacturers at wholesale prices