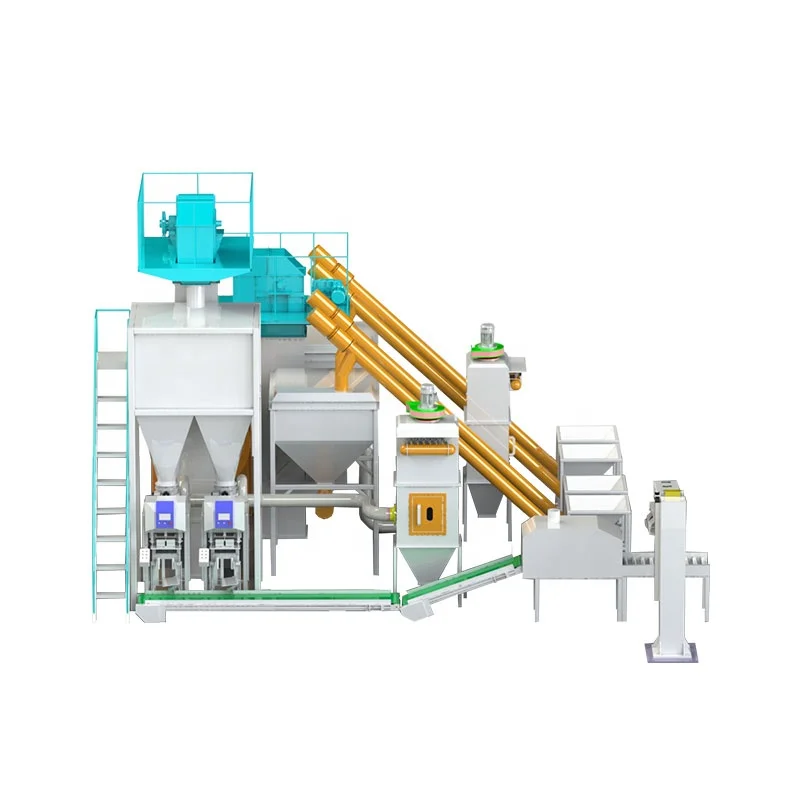

Simple semi automatic ceramic tile adhesive rendering mortar special mortar dry mortar mixing plant production line manufacturer

- Category: >>>

- Supplier: Zhengzhou Tongding Machinery & Equipment Limited Company

Share on (1600977722094):

Product Overview

Description

Long service life large output automatic dry mortar mixer。 Fully automatic dry mortar mixer。 Professional dry mortar production line manufacturers

Equipment Parameter

Model | Host Motor | Capacity(T/H) |

MINI-1000 | 7.5 | 1-3 |

MINI-2000 | 11 | 2-6 |

MINI-3000 | 15 | 3-9 |

MINI-5000 | 22 | 5-10 |

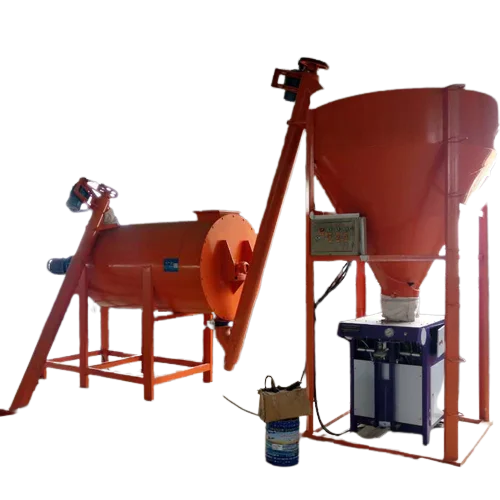

Simple and small dry packaging tile mortar production line is suitable for personal investment, the output can reach 1-10t/h. Simple and small dry powder mortar production line (also known as simple dry powder mortar factory, small putty production line) is on the basis of efficient ribbon powder mixing machine, adding spiral elevator, finished product storage tank, automatic filling and packaging machine, electric control cabinet and other configurations, to form an effective and reasonable, easy to operate production line.

01 Feeding Port

Function: Feed raw materials and additives though the feeding port into the 1st screw convey.

02 1st Screw Conveyor

Function: Conveying materials to the mixer.

Feature:

1) The spiral blade adopts wear-resistant steel;

2) The patent sealing device to prevent the bearings into the dust.

03 Dry Powder Mixer

Feature:

1. The spiral belt wear resistant steel, has a long service life;

2. It is backed by wheel drive settings, to prevent shaft breaking;

3. The motor reducer adopts direct type, stable quality, energy saving and environmental protection.

04 Simple Dust Collector

Function: Collect dust more effectively.

Features: Separation of impurities.

Features: Separation of impurities.

05 Finished Product Hopper

Function: To store the finished product, and equipped with automatic vibration device to ensure that materials can enter the packaging system quickly.

06 Packing Machine

Function: Intelligently pack the finished products in bags. Alternatives 1Valve bag packing machine;2Open bag packing machine;3Ton bag packing machine;4Bulk packing machine.

Simple small dry mortar production line (also known as simple dry mortar plant, small putty production line) can be used for the production of the following products.

1. Bonding mortar, such as tile binder, gap filler, tile grout.

2. Rendering mortar, such as inner and outer rendering mortar, paint putty, coloring.

3. Decorative mortar, insulation mortar, etc.

4. Masonry mortar, ordinary masonry mortar, concrete masonry mortar, AAC brick masonry mortar, etc.

5. Floor mortar, such as ordinary floor mortar, self-leveling mortar, etc.

6. Special mortar, such as repair mortar, waterproof mortar, flexible anti-crack mortar, etc.

1. Bonding mortar, such as tile binder, gap filler, tile grout.

2. Rendering mortar, such as inner and outer rendering mortar, paint putty, coloring.

3. Decorative mortar, insulation mortar, etc.

4. Masonry mortar, ordinary masonry mortar, concrete masonry mortar, AAC brick masonry mortar, etc.

5. Floor mortar, such as ordinary floor mortar, self-leveling mortar, etc.

6. Special mortar, such as repair mortar, waterproof mortar, flexible anti-crack mortar, etc.

Detail Presentation

Please send us your enquiry and we will provide you with the best quality solution.

***Dry mixed mortar plant is a production line that can mass produce dry mixed mortar, which is composed of feeding system, mixing system, weighing system, packaging system,conveying system, etc.mortar multi-functional equipment. Automatic operation, long service life, saving labor costs, high efficiency and environmental protection.

***Automatic mortar line is widely used in metallurgy, chemical industry, casting, building materials, petrochemical, decoration and other industries, suitable for mortar production, cementing materials, putty powder, soil maintenance, masterbatch, additive production, etc.

Case poster

Company Profile

Zhengzhou TONGDING machinery Co., Ltd. is a leading company specializing in the manufacture and sales of Mixing Machines and Dryers.

Our main products include:

1) A simple and environmental friendly dry mortar production line, applicable to all kinds of powders.

2) Dry mortar production line units.

3) Complete set of stone paint production lines.

4) Complete production line of dryers.

5) Machines for thermal insulation mortar and complete set of production lines.

6) Transmission equipment series products.

7) Series of products of packaging equipment.

8) Dust removal equipment, a series of products and various accessories.

We persists in implementing the strategy of improving the competitive ability of our products, relying on a strong R&D team that keeps forging ahead in an innovative way, aiming to be at the forefront of technology, and constantly updating our HI-TECH innovation capability of the corporation. Combining domestic and foreign market demands with development trends, We introduces an advanced international technology,adapting and applying these trends to our products and manufacturing.

We stress our international technical cooperation and communication, and integrate advanced technology from Germany, Sweden, and Finland. We keep the service idea of "Create More Value To Our Customers”, with the times to provide our high quality products,global service and advanced technology for our customers.

Our main products include:

1) A simple and environmental friendly dry mortar production line, applicable to all kinds of powders.

2) Dry mortar production line units.

3) Complete set of stone paint production lines.

4) Complete production line of dryers.

5) Machines for thermal insulation mortar and complete set of production lines.

6) Transmission equipment series products.

7) Series of products of packaging equipment.

8) Dust removal equipment, a series of products and various accessories.

We persists in implementing the strategy of improving the competitive ability of our products, relying on a strong R&D team that keeps forging ahead in an innovative way, aiming to be at the forefront of technology, and constantly updating our HI-TECH innovation capability of the corporation. Combining domestic and foreign market demands with development trends, We introduces an advanced international technology,adapting and applying these trends to our products and manufacturing.

We stress our international technical cooperation and communication, and integrate advanced technology from Germany, Sweden, and Finland. We keep the service idea of "Create More Value To Our Customers”, with the times to provide our high quality products,global service and advanced technology for our customers.

After-sales service

Packing&Delivery

FAQ

Q: How is the quality of your products?

-Our machines are manufactured strictly according to national and international standards, and we can assemble and test all the equipment and pack them carefully before delivery. We have export to lots of countries around the world, such as Australia, Malaysia, India, Indonesia, Vietnam, etc. You can rest assured with the quality absolutely.

Q: What is your business model? Trading company or factory?

-We are a factory with our own mechanical design engineers and project design engineers, all our machinery are manufactured by ourselves.

-We can provide customized solution design according to customer needs, and full-process services such as early project

communication, scheme design, equipment selection, equipment production, site planning, equipment layout, transportation and delivery, installation and commissioning.

Q: Do you provide after-sale service?

-Yes. The warranty period of our machines is 12 months, and we have a professional after-sale service team to promptly and thoroughly solve your problems.

Q: Do you provide equipment operation training?

-Yes. All of our engineers have passports. We can send experienced engineers to the customer's site to guide equipment

installation, debug the production line until it is put into production, we will also provide installation instructions, layout

drawings, assembly drawings, etc. If the customer has his own engineer, he can install the equipment according to the installation steps drawings we provide, and we can also guide the installation with online videos.

Q: Can I visit your factory?

-Yes! Welcome to visit our factory, many domestic and international customers visit our factory every year. We can provide you the invitation letter required for visa application. We will meet you at the airport or station and provide professional business reception services.

Q: What is the process for purchasing equipment?

-Contact customer service —understand the basic situation — equipment quotation — sign contact — equipment production

-Our machines are manufactured strictly according to national and international standards, and we can assemble and test all the equipment and pack them carefully before delivery. We have export to lots of countries around the world, such as Australia, Malaysia, India, Indonesia, Vietnam, etc. You can rest assured with the quality absolutely.

Q: What is your business model? Trading company or factory?

-We are a factory with our own mechanical design engineers and project design engineers, all our machinery are manufactured by ourselves.

-We can provide customized solution design according to customer needs, and full-process services such as early project

communication, scheme design, equipment selection, equipment production, site planning, equipment layout, transportation and delivery, installation and commissioning.

Q: Do you provide after-sale service?

-Yes. The warranty period of our machines is 12 months, and we have a professional after-sale service team to promptly and thoroughly solve your problems.

Q: Do you provide equipment operation training?

-Yes. All of our engineers have passports. We can send experienced engineers to the customer's site to guide equipment

installation, debug the production line until it is put into production, we will also provide installation instructions, layout

drawings, assembly drawings, etc. If the customer has his own engineer, he can install the equipment according to the installation steps drawings we provide, and we can also guide the installation with online videos.

Q: Can I visit your factory?

-Yes! Welcome to visit our factory, many domestic and international customers visit our factory every year. We can provide you the invitation letter required for visa application. We will meet you at the airport or station and provide professional business reception services.

Q: What is the process for purchasing equipment?

-Contact customer service —understand the basic situation — equipment quotation — sign contact — equipment production

We Recommend

New Arrivals

New products from manufacturers at wholesale prices