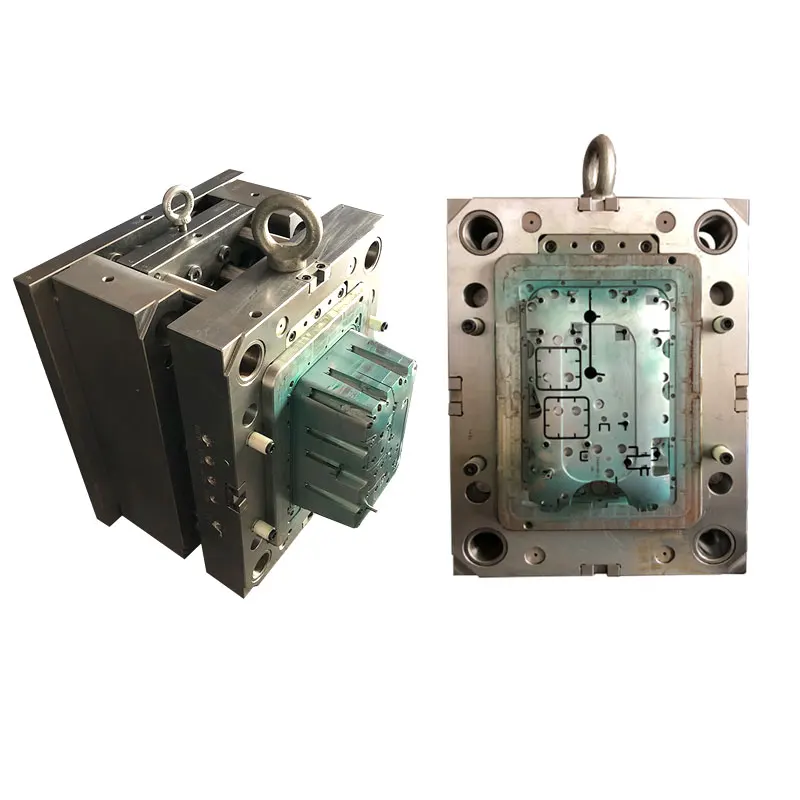

Custom Injection Molds plastic die mould manufacturer thermoset 2 shot injection molding injection moulding products

- Category: >>>

- Supplier: Dongguan Hongsheng Metal Plastic Technology Co. Ltd.Dongguan Ltd.

Share on (1600981931315):

Product Overview

Description

Plastic Materials | HIPS ABS, PC, PP, PS, POM, PMMA, PE, AS, PPSN, PBT, PA66, PC/ABS, etc. |

Mold precision | +/-0.01mm |

Mold Cavity | Single cavity, multi-cavity. |

Rotor system | Hot runner and cold runner. |

570 + Successful Transfers

FAQ

Injection Molding:

What plastics can you use with injection molding?

Injection molding can use virtually any type of plastic, or a combination of them. This versatility is what makes

injection molding so popular for some of the world's most demanding industries. You can view our selection of

available materials and finishes on this page.

Why should I use injection molding?

Injection molding is one of the most affordable ways to manufacture large quantities of parts, especially for bigger

production runs. Even though designing and creating the mold can take time, after that, the process becomes very

affordable and efficient.

What is the process behind injection molding?

The plastic pellets are melted and are then inserted in liquid form into the mold tool, where it cools and takes the

required shape. The process allows for high precision and tight tolerances because it can be replicated exactly each time.

How quickly can you produce parts using injection molding?

Before production can begin, we will first need to design the injection mold tool. How long this takes will depend on the complexity of your project, but the usual timeline can be as short as a week and as long as a couple of months.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices