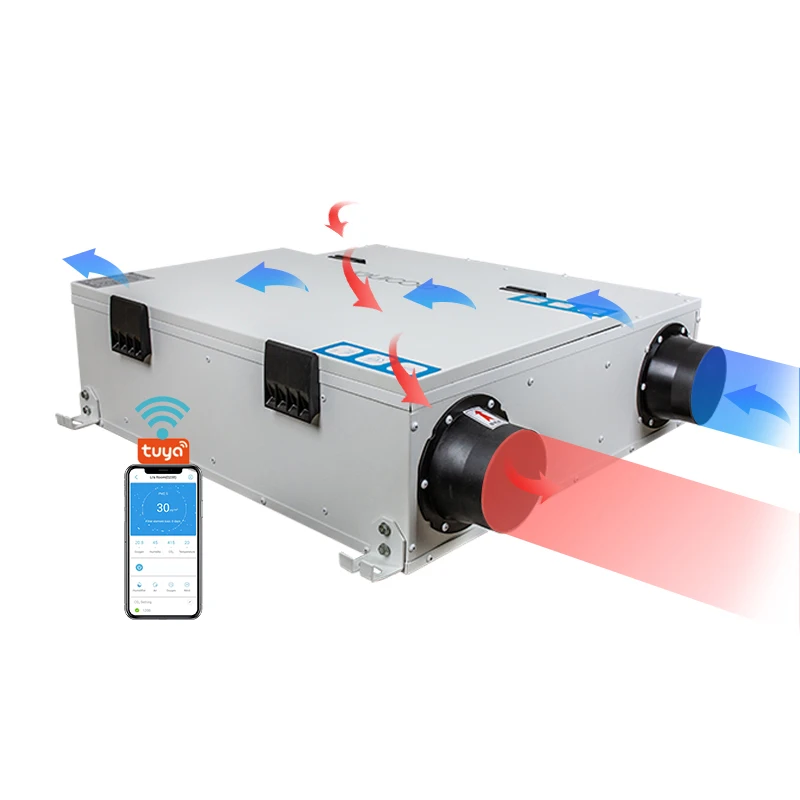

heat recovery unit energy recovery ventilation unit Refrigeration heating hot water Waste heat recovery unit industrial chiller

- Category: >>>

- Supplier: Ningbo Ningshing Trading Group Inc.

Share on (1600988805783):

Product Overview

Description

HVAC System/Centrifugal water chiller unit/Cooling tower system;/Water System Cooling Unit/cooling towers/air cooled module unit/air cooled module unit/Centrifugal Compressor/VRF air conditioning system

PRODUCT SPECIFICATIONS

No | Item | Data |

1 | Type | Central Air Conditioners |

2 | Cooling/Heating | Cooling/Heating |

3 | Applicable Industries | Hotels,Outdoor,Commercial,Household |

4 | Weight (KG) | 68Kg-10000 Kg |

5 | Dimension(L*W*H) | 1010*840*1775 |

6 | Capacity | 8Kw-8790Kw |

7 | Cooling/Heating capacity | 50.4KW/56kw |

8 | EER | 3.27-4.35 |

9 | COP | 3.75-4.99 |

10 | Maximum drive IDU NO. | 29 units |

11 | Refrigerant | R407/R134A/R410a |

12 | Voltage | 208V-575V |

13 | Frequency | 50Hz/60Hz |

Details

Products Description

1.Permanent Magnet Synchronous Frequency Conversion Screw Chiller

Full working condition adaptive screw compressor

Multifunctional horizontal condenser

Full DC control system

Intelligent touch system

Widely application: Rail transit, commercial buildings, data rooms,

manufacturing, hospital pharmaceuticals

Multifunctional horizontal condenser

Full DC control system

Intelligent touch system

Widely application: Rail transit, commercial buildings, data rooms,

manufacturing, hospital pharmaceuticals

2.Series Permanent Magnet Synchronous Inverter Centrifugal Chiller

The world’s first high-power and high-speed PMSM is used for this

centrifugal chiller. Its power is higher than 400 kW and its rotational speed is above 18000 rpm. Motor efficiency is above 96% and 97.5% to the maximum, higher than national grade 1 standard on motor performance. It is compact and lightweight. A 400kW high-speed PMSM weighs the same as a 75kW AC induction motor. By adopting spiral refrigerant spray cooling technology to cool down stator and rotor, motor temperature can be controlled at around 40℃, ensuring efficient operation. High-speed motor direct-driven two-stage impellerUnit adopts high-speed motor direct-driven

two-stage impeller. Speed-up gears and 2 radial bearings are canceled, which will improve efficiency and reduce mechanical loss by at least 70%. With direct drive and simple structure, compressor works reliably in smaller size. Volume and weight of the compressor is only 40% of the same capacity conventional compressor. Without the high-frequency noise of speed-up gears, compressor’s operating sound is much lower. That is 8dBA lower than a conventional unit.

two-stage impeller. Speed-up gears and 2 radial bearings are canceled, which will improve efficiency and reduce mechanical loss by at least 70%. With direct drive and simple structure, compressor works reliably in smaller size. Volume and weight of the compressor is only 40% of the same capacity conventional compressor. Without the high-frequency noise of speed-up gears, compressor’s operating sound is much lower. That is 8dBA lower than a conventional unit.

3.Modular Air Cooled Chiller (Heat Pump)

Holtop HFW series modular air cooled chiller (heat pump) is sophisticated design with fine and elegant configuration, flexible modularized structure. It can be adopted to all kinds of FCU, AHU indifferent specification.

HFW series chiller (heat pump) own itsfeature of high efficiency, low noise, friendly HMI operation, stable and safe running, easy installation and maintenance. The unit canbe widely used for large or small-sized industrial and civil air conditioning project, like factories, station, hotels, villas,office building, high-end apartments etc

HFW series chiller (heat pump) own itsfeature of high efficiency, low noise, friendly HMI operation, stable and safe running, easy installation and maintenance. The unit canbe widely used for large or small-sized industrial and civil air conditioning project, like factories, station, hotels, villas,office building, high-end apartments etc

4.Cooling tower system

Design Features:

The non-rusting FRP casing and basin, circular in shape, eliminates special installation requirements. Prevailing wind directionswill not affect tower performance.

Casing:

Easy access through casing simplifies cleaning. Individual fiberglass panels are stainless steel bolted together for periodic washdown and general clean up.The FRP cooling tower is designed for durability and long life even under the most severe environmental weather conditions.

Fan Blades:

Aerodynamically designed propeller type fan blades are used to conserve power and assure quiet operations. Feature a factory-balanced ABS plastic blade,and all aluminum alloy adjustable fan.

The non-rusting FRP casing and basin, circular in shape, eliminates special installation requirements. Prevailing wind directionswill not affect tower performance.

Casing:

Easy access through casing simplifies cleaning. Individual fiberglass panels are stainless steel bolted together for periodic washdown and general clean up.The FRP cooling tower is designed for durability and long life even under the most severe environmental weather conditions.

Fan Blades:

Aerodynamically designed propeller type fan blades are used to conserve power and assure quiet operations. Feature a factory-balanced ABS plastic blade,and all aluminum alloy adjustable fan.

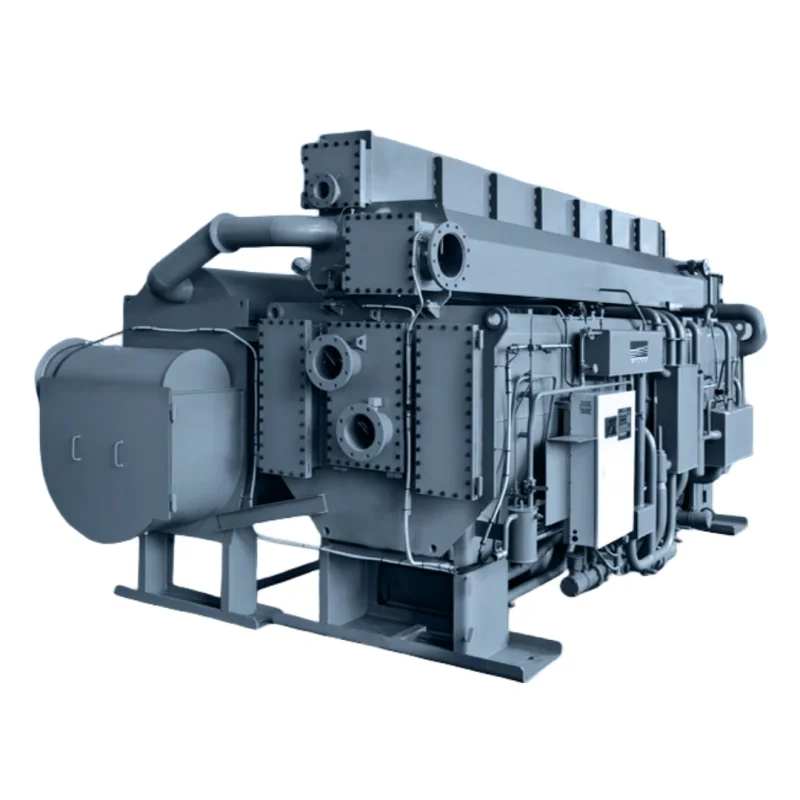

5.Waste heat recovery unit

District Energy is based on one ormore centralized energy stations as the core,and utilizes industrial waste heat,power generation exhaust,biomass energy,natural gas,hydrogen energy,and watersources adapted to local conditions in the region,providing multiple users of cooling,heating,electricity,steam,and hot waterin the area through distribution pipeline network,and achieves the best energy utilization effect with the least emissions.

Title goes here.

Function

Refrigeration, heating, and sanitary hot water(provided simultaneously or separately)

Purpose

* Central air conditioning cold and heat sources

* Prepare cold water above 5 ℃,Hot water below 95 ℃

Refrigeration capacity

233-11630kW(200000 to 10 million kcal/hour)

Energy

* Natural gas, gas, biogasDiesel, recycled oil

* Dual use of oil and gas, multiple energy sources

* Power generation or industrial waste heat(Steam, hot water, smoke, etc.)

Refrigeration, heating, and sanitary hot water(provided simultaneously or separately)

Purpose

* Central air conditioning cold and heat sources

* Prepare cold water above 5 ℃,Hot water below 95 ℃

Refrigeration capacity

233-11630kW(200000 to 10 million kcal/hour)

Energy

* Natural gas, gas, biogasDiesel, recycled oil

* Dual use of oil and gas, multiple energy sources

* Power generation or industrial waste heat(Steam, hot water, smoke, etc.)

6.VRF

Main Features

1) Gree GMV5 All DC Inverter VRF adopts high-efficient DC inverter compressor and DC inverter fan motor.

2) The unit can be combined modularly from 8HP to 88HP. Maximum capacity can up to 180kw.

3) Outdoor unit quiet mode.

4) High energy efficiency with high-performance compressor; Long connection pipe design with the maximum length of 1000m.

5) Auto switch of module status in every 8hrs, which greatly improves the reliability of complete unit.

6) 4 levels of static pressure for option with the maximum of 82Pa.

1) Gree GMV5 All DC Inverter VRF adopts high-efficient DC inverter compressor and DC inverter fan motor.

2) The unit can be combined modularly from 8HP to 88HP. Maximum capacity can up to 180kw.

3) Outdoor unit quiet mode.

4) High energy efficiency with high-performance compressor; Long connection pipe design with the maximum length of 1000m.

5) Auto switch of module status in every 8hrs, which greatly improves the reliability of complete unit.

6) 4 levels of static pressure for option with the maximum of 82Pa.

Cooperative Brand

Certifications

Cooperation Case

Factory Display

We Recommend

New Arrivals

New products from manufacturers at wholesale prices