Chemical Vacuum Jacketed Glass Pilot Plant Reactor Series

- Category: >>>

- Supplier: Aishengke (Jiangsu) Chemical Technology Co. Ltd.

Share on (1600989236479):

Product Overview

Description

product detail presentation

Jacketed glass reactor is mainly applied in Bio-chemical, Pharmaceutical & Fine-Chemical Trades. It can be jointed with vacuum pump, chilling circulator , heating circulator is widely used in the process like Combination, Reaction, Separation,Concentration, etc It is adopted in the industry of chemical products, advanced material synthesis experiment, etc.

Product technical features:

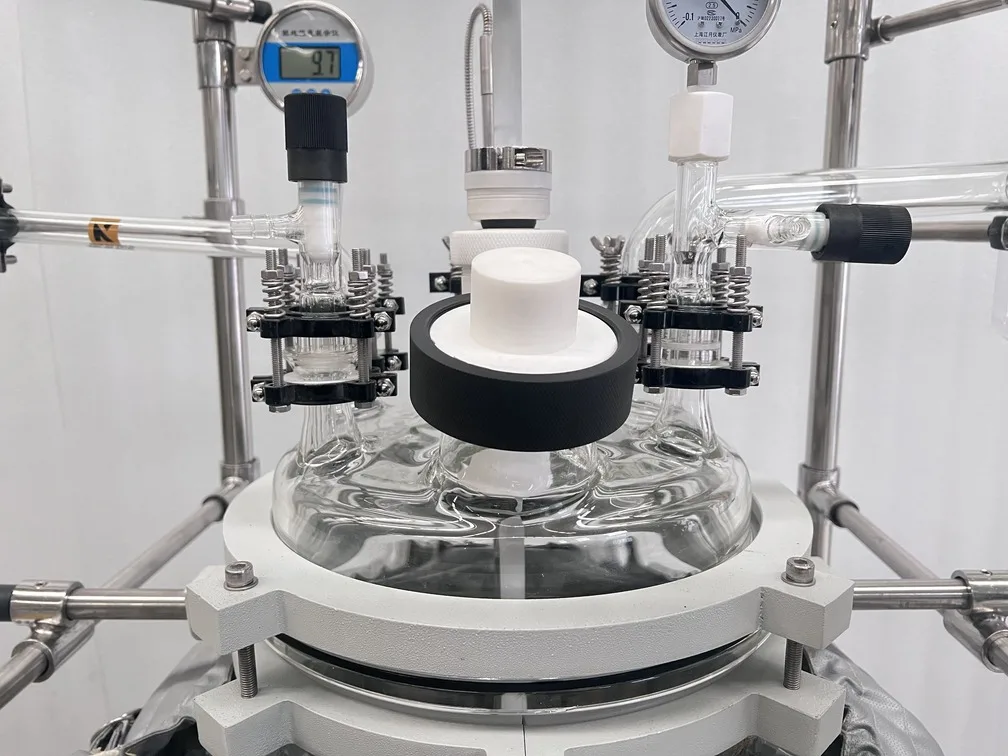

●The glass components are all high borosilicate glass 3.3, which has excellent physical and chemical properties.

●Can be used in the range of high temperature (200°C) to low temperature (-80°C).

●It can work under the pressure condition of -0.1 MPa~0.0 MPa.

●The inlet and outlet of the jacket are connected with stainless steel insulation hoses to eliminate the stress of the inlet and outlet.

●The inlet and outlet of the jacket are connected with stainless steel insulation hoses to eliminate the stress of the inlet and outlet.

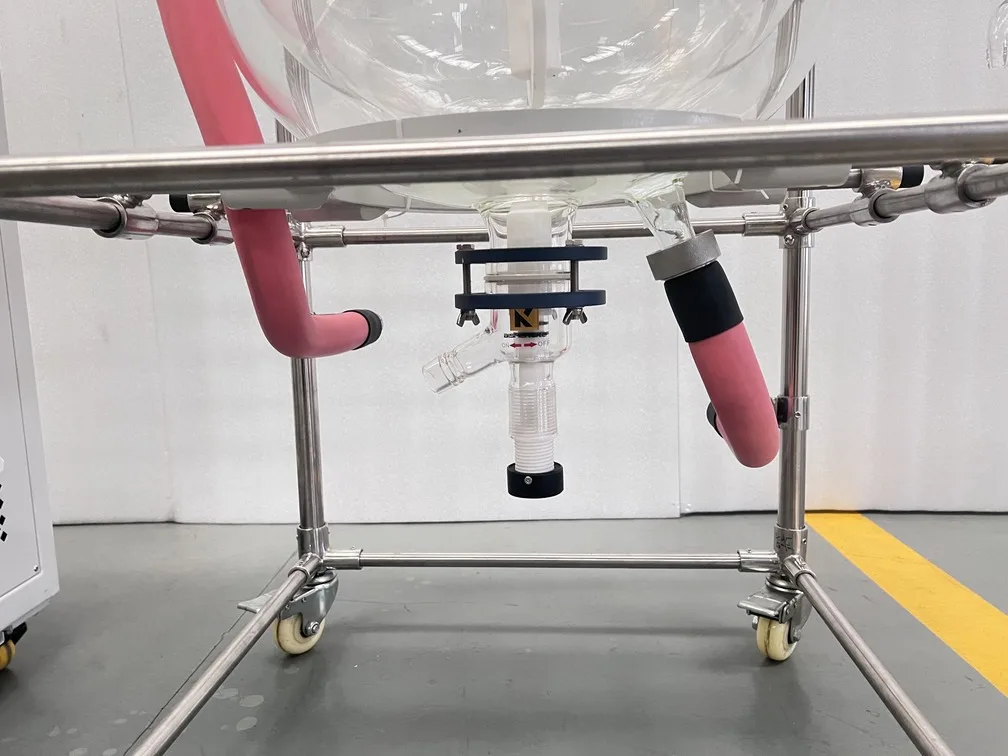

●Anti-corrosion discharge valve designed for side discharge without effusion.

●The main frame is made of SUS304, which has strong corrosion resistance; the lockable caster structure is convenient for equipment movement and positioning.

●Three-phase asynchronous stirring motor, frequency conversion speed regulation, digital display stirring speed.

●Using explosion-proof motor and explosion-proof electric control box, the explosion-proof grade is ExdⅡBT4, and all explosion-proof components have explosion-proof certification of the manufacturer.

● Stirring bearings prevent the agitating rod from wearing and chipping, with good sealing effect and long service life.

●Using Pt100 temperature sensor, high temperature control accuracy, SUS304 material, Teflon tube jacket, double anti-corrosion.

●Paddle type stirring paddle, polytetrafluoroethylene stirring blade; stirring rod material is SUS304, outsourcing polytetrafluoroethylene, high strength, strong corrosion resistance.

Reactor body

A glass baffle is added inside the reactor body, and the baffle design can be added to the jacket to ensure that the reactor body is heated evenly, improve the heat transfer coefficient of the equipment, and ensure high precision of the temperature control of the reactor;

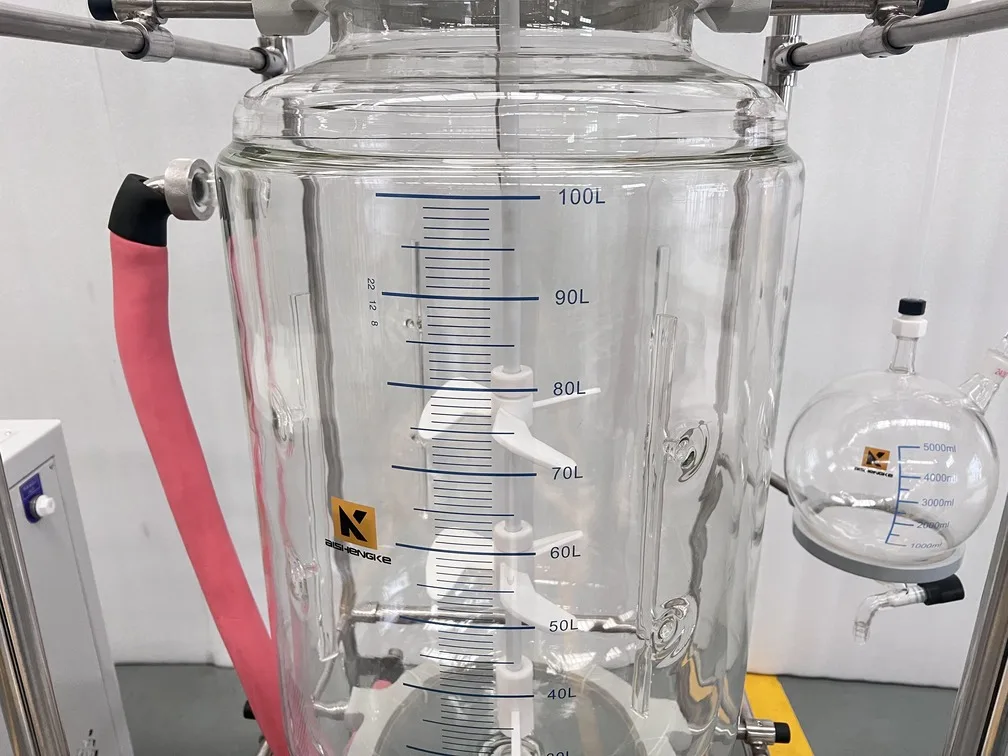

High borosilicate glass firing

Corrosion resistance, high temperature resistance and low expansion rate, fired by current advanced technology, stable chemical properties, high strength, high hardness, high light transmittance. High and low temperature switching is not easy to burst, put an end to inferior products, and make it safer to use.

Paddle type stirring paddle, polytetrafluoroethylene stirring paddle; stirring rod material is SUS304, outsourcing polytetrafluoroethylene, high strength, strong corrosion resistance.

Paddle type stirring paddle, polytetrafluoroethylene stirring paddle; stirring rod material is SUS304, outsourcing polytetrafluoroethylene, high strength, strong corrosion resistance.

Explosion-proof motor

Explosion-proof motor and explosion-proof electric control box are adopted, the explosion-proof grade is ExdⅡBT4, and all explosion-proof components have the manufacturer's explosion-proof certificate

discharge valve

Anti-corrosion discharge valve design, side discharge without liquid accumulation

Main Frame

The main frame is made of SUS304 material, which has strong corrosion resistance; the caster structure can be locked to facilitate the movement and positioning of the equipment.

Model | GR-100L | GR-150L | GR-200L | ||||

Volume(L) | 100 | 150 | 200 | ||||

Jacket volume(L) | 30 | 50 | 60 | ||||

Condensation area(m²) | 1.1 | 1.3 | 1.6 | ||||

Feeding tank volume(L) | 2L | ||||||

Recovery tank volume(L) | 20 | ||||||

Kettle cover diameter | Impeller diameter | 60# flangetype | |||||

Temperature sensor diameter | 40# flangetype | ||||||

Condenser connection | 50# spherical grinding | ||||||

Liquid feed inlet | 34# standard grinding×1 | ||||||

Feeding tank interface | 40# standard grinding | ||||||

Solid feed inlet | 80# flangetype | 120# flangetype | |||||

Glass assembly | High borosilicate glass 3.3 | ||||||

Main frame | SUS304 | ||||||

Stirring paddle | Paddle agitator, internal stainless steel, external polytetrafluoroethylene (PTFE), titanium | ||||||

Motor | For viscous materials, high-power motors can be used | ||||||

Move method | Lockable casters | ||||||

Working temperature(℃) | -120℃~300℃ | ||||||

Maximum temperature difference(℃) | ≤60 | ||||||

Pressure in kettle(MPa) | -0.1~0.1 | ||||||

Jacket pressure resistance(MPa) | ≤0.1 | ||||||

Pressure rise rate of vacuum system | ≤2kPa/h | ||||||

Mixing motor power(W) | Common 200W/ explosion proof 370W | Common 400W/ explosion proof 750W | Common 750W/ explosion proof 750W | ||||

Speed regulation mode | Frequency control | ||||||

Speed adjustment range(rpm) | 0~600 | ||||||

Temperature sensor | PT100 | ||||||

Temperature display accuracy(℃) | ±0.1 | ||||||

Temperature range | Water: RT~90℃ | ||||||

Oil: RT~300℃ | |||||||

Interface size of stainless steel insulation hose | ½in external screw thread | ¾in external screw thread | |||||

Seal material | PTFE | ||||||

Installation height of discharge valve(mm) | 450 | 330 | 330 | ||||

Power | 220V/110V,50/60Hz | ||||||

Environment temperature(℃) | 5~35 | ||||||

Relative humidity(%) | ≤ 65 | ||||||

Size(mm) | 800W×710D×2600H | 1240W×1140D×3100H | |||||

Weight(kg) | 128 | 175 | 190 | ||||

FAQ

1.How to proceed an order ?

A: Firstly let us know your requirements or application. Secondly We quote according to your requirements or our suggestions.

Thirdly customer confirms the samples and places deposit for formal order.

Fourthly We arrange the production.

2.Do you offer guarantee for the products?

A: Yes, we offer 1years warranty to our products.

3.How long is your date of delivery?

A: If the goods are in stock,it is within 7 days. However, it will be 15 days. Also it is depending on the quantity.

4.How to solve the equipment trouble during the using?

A: Please send us email of the problem, pictures or a small video, we will find the problem and help you to solve it.

5.Do you accept OED/ODM?

A: Yes, of course.

6.Do you provide samples? Is it free?

A:Yes, but considering the high value of our products, so the sample is not free.

Welcome to visit our website>>js-ask.en.alibaba.com

Wish You Have A Pleasant Purchasing Time! Pls Click >>Contact Us

1.How to proceed an order ?

A: Firstly let us know your requirements or application. Secondly We quote according to your requirements or our suggestions.

Thirdly customer confirms the samples and places deposit for formal order.

Fourthly We arrange the production.

2.Do you offer guarantee for the products?

A: Yes, we offer 1years warranty to our products.

3.How long is your date of delivery?

A: If the goods are in stock,it is within 7 days. However, it will be 15 days. Also it is depending on the quantity.

4.How to solve the equipment trouble during the using?

A: Please send us email of the problem, pictures or a small video, we will find the problem and help you to solve it.

5.Do you accept OED/ODM?

A: Yes, of course.

6.Do you provide samples? Is it free?

A:Yes, but considering the high value of our products, so the sample is not free.

Welcome to visit our website>>js-ask.en.alibaba.com

Wish You Have A Pleasant Purchasing Time! Pls Click >>Contact Us

We Recommend

New Arrivals

New products from manufacturers at wholesale prices