Desktop LED UV Curing Conveyor System with 365nm 395nm 405nm 200*100mm 600W LED UV Curing Lamp

- Category: >>>

- Supplier: Zhongshan Enbo Optoelectronics Co. Ltd.Zhongshan Ltd.

Share on (1601011211689):

Product Overview

Description

Products Description

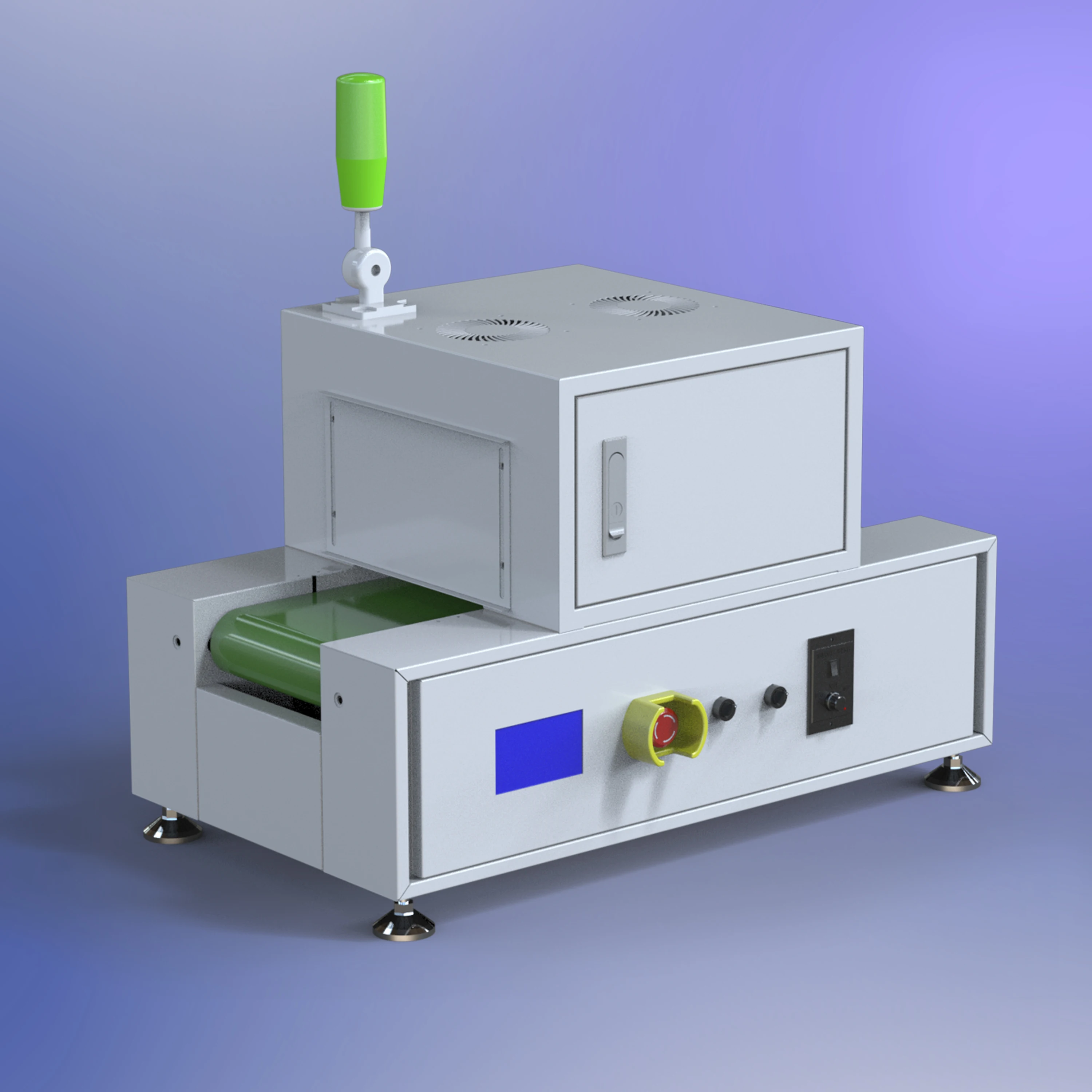

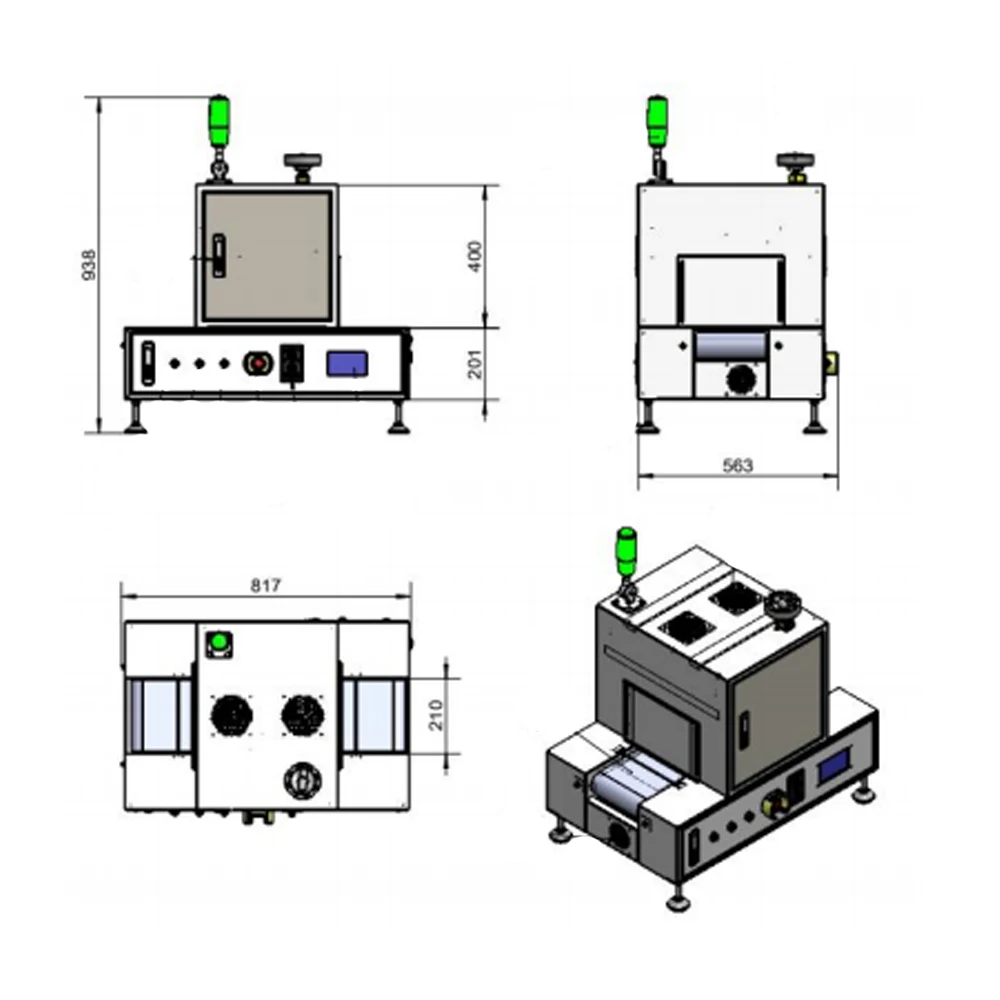

Desktop LED UV Curing Conveyor

EB-DK200 is desk LED UV curing conveyor system with 200mm conveyor belt width; 600mw-18000mw/cm2 optional. This a compact solution designed for efficiency. The conveyor features a standard width of 200mm, with material options including Teflon, stainless steel, PVC, and more. The standard height from the lamp heads to the conveyor belt is adjustable from 10mm to 180mm.

Desktop Conveyor System

The conveyor features a standard width of 200mm, with material options including Teflon, stainless steel, PVC, and more. The standard height from the lamp heads to the conveyor belt is adjustable from 10mm to 180mm. With a maximum conveyor belt speed of 5m/min, customizable to other speeds, this desktop conveyor provides versatility. Its small footprint makes it ideal for various settings.

200*100mm LED UV Lamp Head

Equipped with a 200*100mm LED UV Flood Curing Lamp r allowing for 0-100% control of the internal working power.

The internal LED UV curing lamp’s size and wavelength intensity are adaptable to user preferences, making it an ideal choice for curing small areas of UV materials such as adhesives, inks, coatings, and more.

Details Images

Product Paramenters

Features

1. High Efficiency: Capable of reaching a UV intensity of up to 18000w/cm² for rapid curing of UV materials.

2. Versatility: Offers multiple UV wavelength options (365nm, 395nm, 405nm, etc.) to accommodate a variety of material requirements.

3. User-Friendly Design: Features a 5-inch touch control display for easy operation and power control from 0-100%.

4. Standard Width and Material Options: The conveyor features a standard width of 200mm, and users can choose from materials such as Teflon, stainless steel, PVC, among others.

5. Professional Suitability: Ideal for use in medical, electronic, and laboratory settings.

2. Versatility: Offers multiple UV wavelength options (365nm, 395nm, 405nm, etc.) to accommodate a variety of material requirements.

3. User-Friendly Design: Features a 5-inch touch control display for easy operation and power control from 0-100%.

4. Standard Width and Material Options: The conveyor features a standard width of 200mm, and users can choose from materials such as Teflon, stainless steel, PVC, among others.

5. Professional Suitability: Ideal for use in medical, electronic, and laboratory settings.

FAQ

1: Why choose our UV LED curing system?

A: ENBO has over 10 years combined experience in UV LED curing industry and we supply full size of LED UV Curing systems including most of UV applications.

2: What's the application of our UV LED curing system ?

A:UV LED curing system can be used for curing UV adhesives, UV ink, UV paint, UV varnish and other UV sensitive materials, which covers many industries such as electronics, medical, and printing.

3: What is the major advantages of UV LED curing system’s than other UV curing system?

A:Extra-long life, energy saving and environment friendly.

4: Which wavelength do I need?

A:It depends on your UV sensitive materials.

5: What's the emitting window do I need?

A:It depends on your product’s size that need to be cured.

6: What's the Peak UV Intensity do I need?

A:It depends on your UV sensitive materials and your Production efficiency.

7: The common emitting window and Peak UV Intensity can not meet my requirements?

A:Do not worry! Any sizes of emitting window and Peak UV Intensity can be customized .

For product trials or customization, please contact us.

A: ENBO has over 10 years combined experience in UV LED curing industry and we supply full size of LED UV Curing systems including most of UV applications.

2: What's the application of our UV LED curing system ?

A:UV LED curing system can be used for curing UV adhesives, UV ink, UV paint, UV varnish and other UV sensitive materials, which covers many industries such as electronics, medical, and printing.

3: What is the major advantages of UV LED curing system’s than other UV curing system?

A:Extra-long life, energy saving and environment friendly.

4: Which wavelength do I need?

A:It depends on your UV sensitive materials.

5: What's the emitting window do I need?

A:It depends on your product’s size that need to be cured.

6: What's the Peak UV Intensity do I need?

A:It depends on your UV sensitive materials and your Production efficiency.

7: The common emitting window and Peak UV Intensity can not meet my requirements?

A:Do not worry! Any sizes of emitting window and Peak UV Intensity can be customized .

For product trials or customization, please contact us.

Company Profile

Zhongshan Enbo Optoelectronics Co., Ltd. is a manufacturer specializing in the production of LED functional lighting used in professional equipment. We have more than ten years of LED production and 8 years of foreign trade experience, and have been actively recognized and trusted by many partners. In recent years, we have begun to focus on the provision of professional equipment lighting solutions, and continue to optimize and innovate products. Our products are all CE and ROHS certificated , some of our lights are UL compliant, we strictly follow EU electrical safety standard. Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction.

Attentions

1. General precautions

In the attached connection cable, the LED irradiation head connection cable can be used to be bent.

Under the standard test conditions, the bending performance of the cable is satisfied.

However, its performance under any conditions of actual use cannot be guaranteed.

Do not disassemble, modify or set up inside.

Breakdown, modification and use caused by failure, damage and other circumstances, will not be within the scope of warranty.

2. Install the environment

● Installation and use of ambient temperature and humidity 0℃ -+ 45℃, ≤85%RH (no condensation, freezing)

● Temperature and humidity of storage environment -10℃ -+ 60℃, ≤85%RH (non-condensation, freezing)

● Dust, soot, conductive dust, corrosive, flammable gas, salt, iron, etc

● No contact with water, oil, medicine and other places

● No severe temperature change and vibration, impact of the place without direct sunlight, no strong magnetic field, strong electric field

3. About power supply and wiring

● Please supply single-phase 180V-240V (frequency 50Hz-60Hz) power supply voltage, and grounding.

● Do not use the same power cord with the motor and the induction machinery or the high-power device.

● For the wiring between the controller and the LED irradiation head, please use the attached cable and connect. In the attached connection cable, the LED irradiation head connection cable can be used to be bent.

● When used in bending, as a minimum bending radius greater than 110mm, please execute the design of the system. Bending with radius less than recommended, there is a possibility of rupture occurring in a very short time period.

4. About installation

● When installing the controller and irradiation head, keep it level. Do not tilt, tip or reverse install. Otherwise, it may lead to fever and damage.

● Do not install in a confined space. Do not block the radiator vents.

5. Precautions for power connection

● Before switching on the power supply, please confirm all connections are correct.

In the attached connection cable, the LED irradiation head connection cable can be used to be bent.

Under the standard test conditions, the bending performance of the cable is satisfied.

However, its performance under any conditions of actual use cannot be guaranteed.

Do not disassemble, modify or set up inside.

Breakdown, modification and use caused by failure, damage and other circumstances, will not be within the scope of warranty.

2. Install the environment

● Installation and use of ambient temperature and humidity 0℃ -+ 45℃, ≤85%RH (no condensation, freezing)

● Temperature and humidity of storage environment -10℃ -+ 60℃, ≤85%RH (non-condensation, freezing)

● Dust, soot, conductive dust, corrosive, flammable gas, salt, iron, etc

● No contact with water, oil, medicine and other places

● No severe temperature change and vibration, impact of the place without direct sunlight, no strong magnetic field, strong electric field

3. About power supply and wiring

● Please supply single-phase 180V-240V (frequency 50Hz-60Hz) power supply voltage, and grounding.

● Do not use the same power cord with the motor and the induction machinery or the high-power device.

● For the wiring between the controller and the LED irradiation head, please use the attached cable and connect. In the attached connection cable, the LED irradiation head connection cable can be used to be bent.

● When used in bending, as a minimum bending radius greater than 110mm, please execute the design of the system. Bending with radius less than recommended, there is a possibility of rupture occurring in a very short time period.

4. About installation

● When installing the controller and irradiation head, keep it level. Do not tilt, tip or reverse install. Otherwise, it may lead to fever and damage.

● Do not install in a confined space. Do not block the radiator vents.

5. Precautions for power connection

● Before switching on the power supply, please confirm all connections are correct.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices