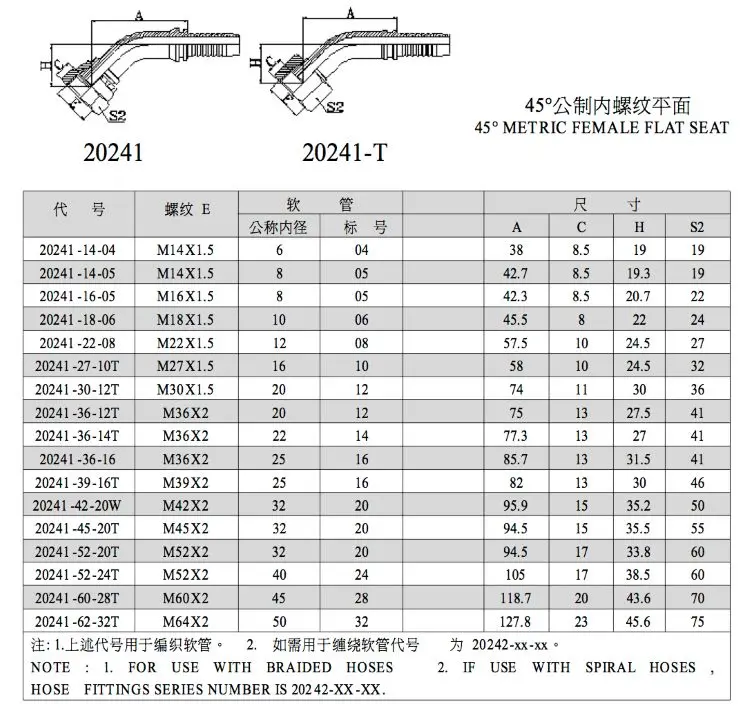

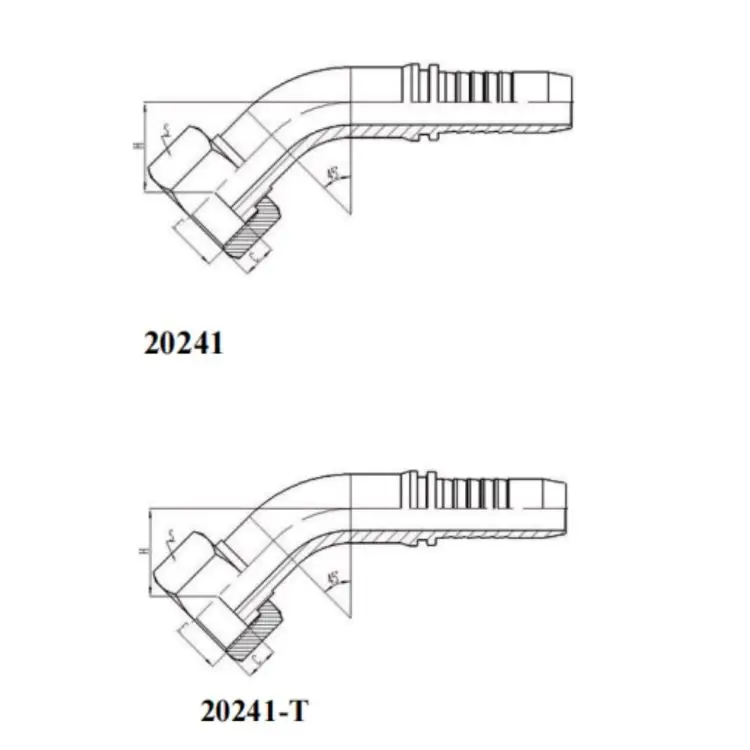

Hydraulic Metric Fittings 20241 45 degree Metric Flat Seat Fitting

- Category: >>>

- Supplier: Dongguan Leqian Plastic Hardware Products Co. Ltd.

Share on (1601011266570):

Product Overview

Description

Hydraulic Metric Fittings-20241 45 degree Metric Flat Seat Fitting

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish, |

| Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing, | |

| electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), | |

| Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc. | |

| Main Equipment | CNC Machining center(Milling), CNC Lathe, Grinding machine, |

| Cylindrical grinder machine, Drilling machine, Laser Cutting Machine,etc. | |

| Drawing format | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm |

| CNC milling work range: 510mm*1020mm*500mm |

Photos for Hydraulic Metric Fittings-20241 45 degree Metric Flat Seat Fitting

What is CNC Machining?

CNC, or computer numerical control machining, is a widely used manufacturing process that uses automated, high-speed cutting tools to form designs from metal or plastic stock. Standard CNC machines include 3-axis, 4-axis, and 5-axis milling machines, lathes, and routers. Machines may vary in how CNC parts are cut—the workpiece may remain in place while the tool moves, the tool may remain in place while the workpiece is rotated and moved, or both the cutting tool and workpiece may move together.

Skilled machinists operate a CNC machine by programming tool paths based on the geometry of the final machined parts. The part geometry information is provided by a CAD (computer-aided design) model. CNC machines can cut almost any metal alloy and rigid plastic with high precision and repeatability, making custom machined parts suitable for nearly every industry, including aerospace, medical, robotics, electronics, and industrial. Xometry offers custom CNC quotes on over 40 materials ranging from commodity aluminum and acetal to advanced titanium and engineered plastics like PEEK and Teflon.

How CNC Turning Works

CNC turning (also known as CNC lathes) is a subtractive manufacturing process in which a stationary cutting tool removes material by making contact with the spinning workpiece to create the desired shape.

During processing, a blank bar of stock material is held in the chuck of the spindle and rotated with the spindle. Extreme precision and repeatability can be achieved under the control of computer instructions for the movement of the machinery.

When CNC turning rotates the workpiece in a chuck, it’s generally to create round or tubular shapes and achieve far more accurate rounded surfaces than CNC milling or other machining processes.

1. Chuck: Fixes the bar of stock material for machining

2. Spindle: Rotates the chuck across axes for material forming.

3. Turret: Moves the stock bar in line with the computer-aided manufacturing (CAM) blueprint or computer-aided design (CAD).

4. Interface: Provides options for the operator to control and use the turning centers.

CNC Milling :

CNC machining services have advanced 3-, 4-, to 5- axis milling centers. The high-quality milled products are involved in the field of automation design, machine tool machining, medical equipment, lighting parts machining, etc.

What is CNC Milling

CNC milling is to cut solid plastic or metal material into final precision parts using different axis milling processes. Unlike CNC lathes, CNC mills remove material from the workpiece by rotating and moving a cutting tool, such as a milling cutter, and position the workpiece properly, to create a finished or semi-finished shape.

The multi-axis milling machines realize a versatile, accurate, and repeatable CNC milling process for the production of different features and complex geometries. Take channels, holes, curves, and corners for some examples. Milling can be also used as a perfect way of making tooling for die casting and injection molding.

Our advanced facilities conclude imported 3-axis, 4-axis, and 5-axis CNC mills that are equipped with different tool sets to maximize production efficiency and speed.

Our Advantage:

1.Competitive price.

2.Continuance service and support.

3.Diversified rich experienced skilled workers.

4.Custom R&D program coordination.

5.Application expertise.

6.Quality,reliability and long product life.

7.Mature,perfect and excellence,but simple design.

Quality Control:

1) Technicians self-check in production

2) Engineer spot check in production

3) QC inspects after mass production finished

4) International sales who were trained the technical know-how spot check before shipping

We Recommend

Codo Cobre 90 Deg Elbow Custom Copper Press Fittings 90 Degree Elbow

Factory Custom Made Precision Brass Pipe Fittings

New Arrivals

New products from manufacturers at wholesale prices