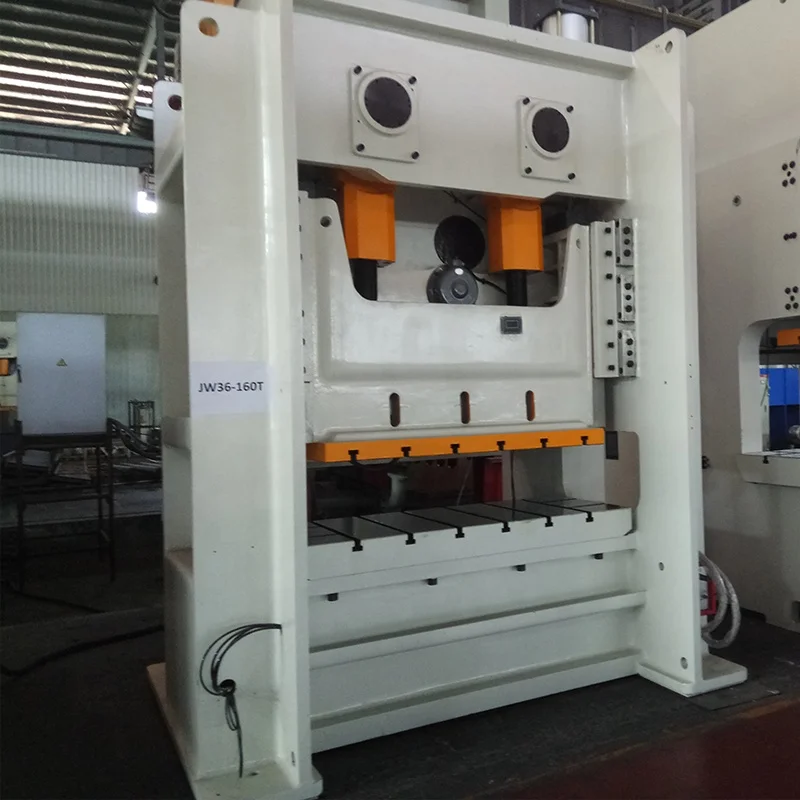

High precision JW36 160T Straight side two point press Stamping Punch Machine /Double Crank Power Press Machine

- Category: >>>

- Supplier: Wuxi Mingxu Machinery Equipment Co. Ltd.

Share on (1601012013354):

Product Overview

Description

Products Description

Professional stamping equipment manufacturing has reached 68 years

C-Frame Fixed Bolster Press

C-Frame Two Point Press

Straight-side Two-point Press

JW36 Series Features

● Whole welding, low deformation, especially suitable for processing fine progressive mold;

● Adopts double crankshaft reverse driving and eccentric load resisting guideway to enhance the eccentric load resistance ofmachine tool;

● Adopts 4-corner 8-face long guideway for sliding block with excellent guiding performance and high accuracy;

● Adopt high torque wet type friction clutch featuring stable operation, low noise, long service life and high safety and reliability.

● Electrical adiusted mold and reading accuracy to 0.1mm.

● Adopts centralized lubrication and is equipped with circulation indication device.

● High safety and multi-function electronic control system.

●Be able to be equipped with various automation peripheral equipment so as to improve the production efficiency.

Technical Parameter

SpecidicatIons | Unit | JW36-110T | JW36-160T | JW36-200T | ||||||

Type | S | H | S | H | S | H | ||||

Nominal Pressure | kN | 1100 | 1600 | 2000 | ||||||

Nominal Stroke | mm | 5 | 3 | 6 | 3 | 7 | 3 | |||

Slide Stroke | mm | 180 | 110 | 200 | 130 | 250 | 150 | |||

Slide Stroke Per Mintue(Fixed) | min-1 | 50 | 60 | 45 | 60 | 35 | 50 | |||

Slide Stroke Per Mintue(Variable) | min-1 | 35-60 | 40-70 | 35-55 | 40-70 | 25-40 | 30-60 | |||

Max Die Set Height | mm | 400 | 435 | 450 | 485 | 500 | 550 | |||

Die Height Adjustment | mm | 90 | 100 | 110 | ||||||

Distance Between Uprights | mm | 1750 | 1900 | 2290 | ||||||

Slide bottom Size | mm | 1350*600 | 1500*700 | 1900*800 | ||||||

Shank Hole Size | mm | 3-60*80 | 3-60*85 | 3-70*90 | ||||||

Bolster Size | mm | 1650*700 | 1800*760 | 2200*900 | ||||||

Bolster Thickness | mm | 140 | 150 | 170 | ||||||

Bolster Surface Height | mm | 1035 | 1035 | 1135 | ||||||

Dimensions Of Side Hole | mm | 650*350 | 800*400 | 900*450 | ||||||

Motor Power | kW | 11 | 18.5 | 22 | ||||||

Overall Dimensions | mm | 1900*2600*3900 | 2300*2700*4000 | 2550*3200*4400 | ||||||

Weight(Approximate) | kg | 18000 | 21500 | 31500 | ||||||

Press Pressure | Map | 0.5 | 0.5 | 0.5 | ||||||

● Standard Equipments JW36 标准配置

●Wet clutch(World)

●Hydraulic overload protecting pump

●Auto lubrication system

●Manual lubrication system

●Balance cylinders for slide and upper die

●Digital die height indicator

●Joint for miss-feeding

●Touch screen

●Electronic crankshaft angle indicator

●Cam controller

●Rotary encoder

●Movable operation panel

●Die height adjusted motor

●PLC :Programmable logical controller

●Air source quick connector

●Air Blowing device

●Shock Absorption Pads

੦ Optional Equipments

૦ Light curtain

૦ Foot pedal

૦ Air cushion device·

૦ Die quick change device

૦ Frequency changer

૦ Foot pedal

૦ Air cushion device·

૦ Die quick change device

૦ Frequency changer

૦ Knock out device(Shank hole)

૦ Foundation bolts

૦ Flywheel rear side maintenance platform

૦ Foundation bolts

૦ Flywheel rear side maintenance platform

HIGH PRECISION FOR SHEET MATAL PUNCHING AND STAMPING

The press body is milling and boring by PAMA machine center and all the surfaces and holes will be finished machining in one position.

HIGH PERFORMANCE WET CLUTCH

Wet type pneumatic clutch with imported clutchdisc, NOK seals, lower noise and maintenancecost, longer service life.

HYDRAULIC OVERLOAD PROTECTED PUMP

The press is standard equipped with JapaneseSHOWA hydraulic overload pump.Normally thesystem is set as 110% of the nominal capacity.

KEY PARTS OF RESIN SAND CASTING

The key components and parts, such as slidingblock, guiderail working table,connecting rod, and flywheel, etc. are cast by resin-bondedsand by which the surface roughness can be improved by 1 to 2 levels and the dimensional precision can be improved by 2 to 3 levels compared with common clay sand cast.

PANASONIC OR OMRON OR SCHNEIDER PLC

PLC control system can be Panasonic or Omron or Schneider brand.

HMI FOR EASY OPERATION

HMl according to the working time or working stroke times. HMI with setting function,|/0 monitor counter and preset counter.

Inverter to adjuststroke speed

Piston type die cushion

Light curtain Protection

Die quick change device

Decoiler and NC feeder

3 in 1 servo NC feeder

Note:User selection shall be indicated in the contract

Company Profile

Certifications

Product packaging

FAQ

1. Who are we?

A: Our company is mainly engaged in machine tools and equipment. It is located in Wuxi, Jiangsu Province. The company sells and produces presses, shearing machines, bending machines, lathes, CNC machine tools, milling machines, grinding machines, drilling machines and other products in machining centers.

2.What is the package of the machines?

A: The machines standard packed by iron pallets with steel box ,high quality package to reduce the risk of damage during delivery.

3.What is your MOQ of this item?

A: Our MOQ is one set.

4.How can I choose the most suitable machines ?

A: Please let us know your machining demand or machine size ,we can choose the best model for you , or you can choose the exact model by yourself. You can also send us the products drawing ,we will choose the most suitable machines for you .

5.When is the delivery time?

A: Conventional Machines, we will deliver then within 20 working days after receiving your deposit. If some special machines will be longer, please contact us for details. According to the delivery date at that time, we will give you a reply accordingly.

6. What is the payment Terms ?

A : Alibaba or T/T ,30% initial payment when order ,70% balance payment before shipment ;

7.What kind of trade terms can you do ?

A:EXW,FOB,CFR,CIF,Etc.

8.What is Trade Assurance?

A:Trade Assurance is a free service by Alibaba .com that's designed to help create trust between buyers and suppliers.Trade Assurance helps buyers in the event of shipping and quality-related dispute.

9.Dose Trade Assurance charge fees?

A: No.Trade Assurance is free for both buyers and suppliers.

A: Our company is mainly engaged in machine tools and equipment. It is located in Wuxi, Jiangsu Province. The company sells and produces presses, shearing machines, bending machines, lathes, CNC machine tools, milling machines, grinding machines, drilling machines and other products in machining centers.

2.What is the package of the machines?

A: The machines standard packed by iron pallets with steel box ,high quality package to reduce the risk of damage during delivery.

3.What is your MOQ of this item?

A: Our MOQ is one set.

4.How can I choose the most suitable machines ?

A: Please let us know your machining demand or machine size ,we can choose the best model for you , or you can choose the exact model by yourself. You can also send us the products drawing ,we will choose the most suitable machines for you .

5.When is the delivery time?

A: Conventional Machines, we will deliver then within 20 working days after receiving your deposit. If some special machines will be longer, please contact us for details. According to the delivery date at that time, we will give you a reply accordingly.

6. What is the payment Terms ?

A : Alibaba or T/T ,30% initial payment when order ,70% balance payment before shipment ;

7.What kind of trade terms can you do ?

A:EXW,FOB,CFR,CIF,Etc.

8.What is Trade Assurance?

A:Trade Assurance is a free service by Alibaba .com that's designed to help create trust between buyers and suppliers.Trade Assurance helps buyers in the event of shipping and quality-related dispute.

9.Dose Trade Assurance charge fees?

A: No.Trade Assurance is free for both buyers and suppliers.

Phone: 0086-13771085841

E-mail: yingyingmxjd@163.com

Wechat: 137-7108-5841

Whatsapp: 08613771085841

Address:5-4,5-5,Fortune Commercial Plaza, Xinwu District,Wuxi,Jangsu,China

Recommend Products

We Recommend

New Arrivals

New products from manufacturers at wholesale prices