Food Grade Sodium Alginate Cosmetic Grade Industrial Grade 90% CAS 9005 38 3 Textile Industry Thickener 20 1000cps

- Category: >>>

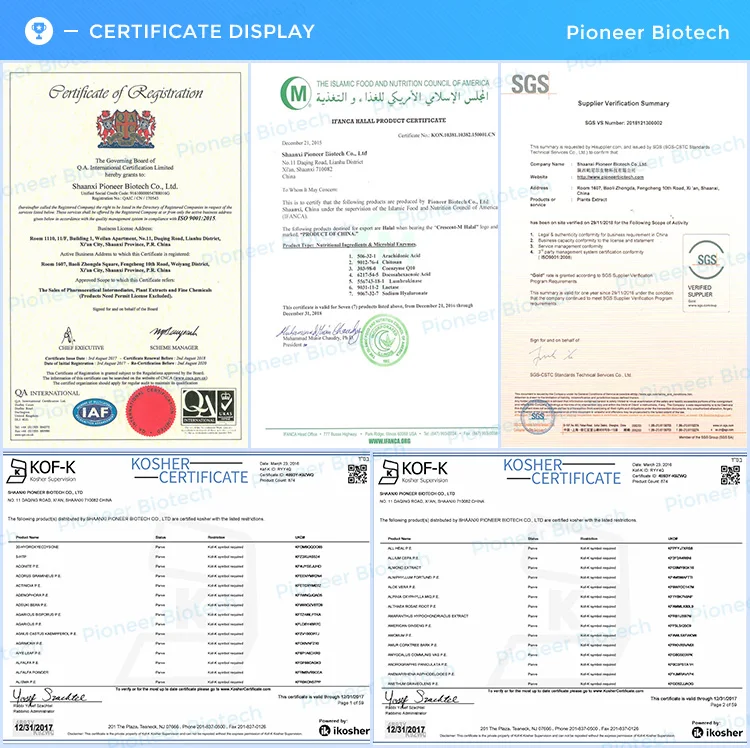

- Supplier: Shaanxi Pioneer Biotechnology Co. Ltd

Share on (1601014996406):

Product Overview

Description

Product name: Sodium Alginate

Cas No: 9005-38-3

Molecular Formula: C5H7O4COONa

Introduction: Sodium alginate is a by-product after extracting iodine and mannitol from kelp or Sargassum. Its molecule is composed of β-D- mannuronic acid (M) and α-L- guluronic acid (G) connected by (1→4) bond. It is a natural polysaccharide and has the stability required by pharmaceutical excipients. Sodium alginate has been widely used in food industry and medicine.

Test Items | Specifications | Result |

Mesh | 100% pass 80 mesh | 80mesh |

Character | Fine white powder | Qualified |

Identify | Meet the tests | Qualified |

Viscosity(mPa.s) | 20-1000 mPa.s | 20 ~ 1000 mPa.s |

Clarity & color | Qualified | Qualified |

pH Value | 6 ~ 8 | 7.1 |

Loss on drying | ≤15% | 11.8% |

Ash Content | 18.0% ~ 27.0% | 24.6% |

Pb | ≤0.005% | <0.005% |

As | ≤0.002% | <0.002% |

Total aerobes (cfu/g) | ≤103 | <1*40 |

Yeasts Moulds (cfu/g) | ≤102 | <1*40 |

Escherichia Coli | Negative/g | Negative |

Salmonella | Negative/10g | Negative |

1. Sodium alginate is used to replace starch and gelatin as the stabilizer of ice cream, which can control the formation of ice crystals, improve the taste of ice cream, and also stabilize mixed drinks such as sugar sorbet, sherbet and frozen milk. Many dairy products, such as refined cheese, whipped cream, dry cheese, etc., can prevent the food from sticking to the packaging by using the stabilizing effect of sodium alginate, and can be used as the cover of the upper milk jewelry, which can make it stable and prevent the icing crust from cracking.

Sodium alginate is used as a thickener for salad (a cold salad) sauce and pudding (a dessert) canned products to improve the stability of products and reduce liquid leakage.

2. Sodium alginate is also used in the production of suspensions, gels and concentrated emulsions based on fats and oils. Sodium alginate is used in some liquid drugs, which can enhance the viscosity and improve the suspension of solids. Propylene glycol alginate can improve the stability of emulsion.

3. Sodium alginate is used as reactive dye paste in printing and dyeing industry, which is superior to grain starch and other pastes. Printed textiles have bright patterns, clear lines, high color feed, uniform color, good permeability and plasticity. Algae gum is the best size in modern printing and dyeing industry. It has been widely used in the printing of cotton, wool, silk, nylon and other fabrics, especially in the preparation of pad printing paste.

In China textile department, seaweed gum mixed with starch or used instead of starch to prepare warp sizing agent can not only save a lot of grain, but also make warp fibers lint-free, friction-resistant, and have less broken ends, thus improving weaving efficiency. Algae gum is effective for both cotton fiber and synthetic fiber.

4. PS barium sulfate preparation for gastrointestinal double contrast made of alginate sulfate dispersant has the characteristics of low viscosity, fine particle size, good adhesion to the wall and stable performance.

PSS is a kind of sodium fucoidan diester developed from alginic acid, which has the functions of anticoagulation, blood lipid reduction and blood viscosity reduction.

Using seaweed glue instead of rubber and gypsum as dental impression material is not only cheap and easy to operate, but also the printed tooth profile is more accurate.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices