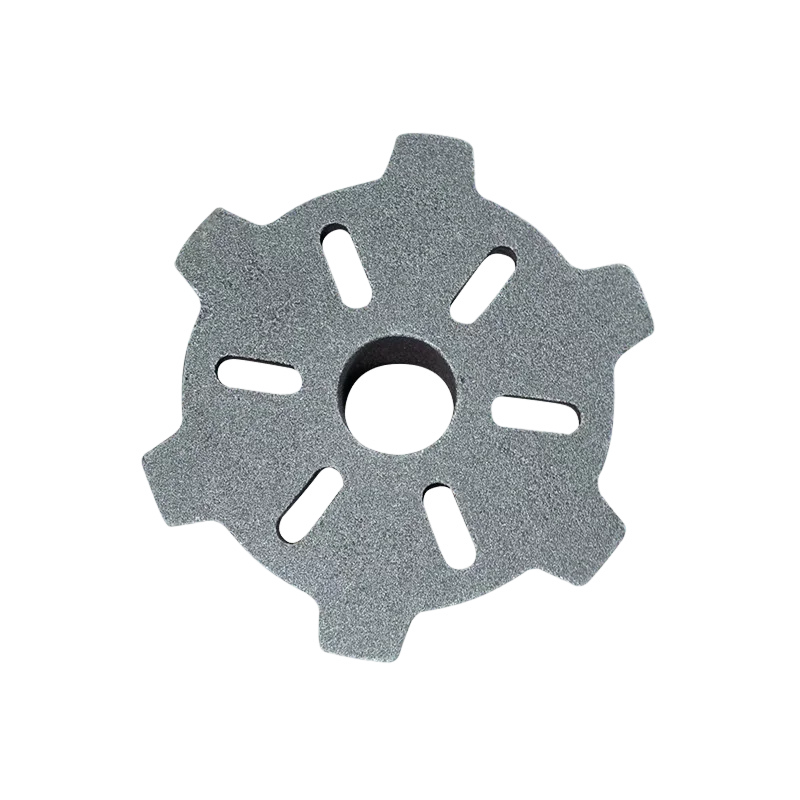

iron sand casting auto parts truck parts

- Category: >>>

- Supplier: Qingdao Seger Industrial Co. Ltd.Qingdao Ltd.

Share on (1601015581650):

Product Overview

Description

Specification

Service | OEM ODM |

Material | Grey Iron, Ductile Iron,stainless steel,carbon steel,aluminum,brass etc |

Application | Industry Machinery, Automotive, Electricity,marine,hardware,home decoration,railway parts etc |

Process | Mould, Casting, CNC Machining,Assembly,Packing |

Machining Process | CNC Lathe, CNC milling center |

Heat treatment | Annealing, Quench and temper, ADI |

Surface treatment | Shot blasting, Anodized with a different color (Clear Anodized, Black ANodized, etc), Brushing, Hot dip galvanized, Electro-Galvanized, Power painted, Painting, Coating |

Quality Control | PFMEA, PPAP, APQP, Control Plan, MSA |

Testing facilities | Spectrometer, CMM, Callipers, micrometer, projector Load test machine, Hardness tester, roughmeter |

Machining tolerance | +/-0.005mm, ISO2768-mk |

Casting tolerance | CT4-CT9 |

Certificate | ISO 9001 |

Product Description

ADI casting iron

We offer advice and technical assistance in ensuring the suitability of A.D.I.for each unique application, including prototype and

pre-production development as required.

pre-production development as required.

Cast Iron Wheel Hub

OEM&ODM design as per client's drawing and sample photo

Cast Iron Impeller

The impeller could be stainless steel,iron,brass material which could be as required.Dynamic balancing testing as required for each impeller when necessary

Cast iron parts for auto

Machining could be as per drawing.High precision tolerance

One-year warranty will be indicated on sales contract or proforma invoice.

All the products will be fully inspected before delivery.

Packing & Delivery

Inspection

Company Profile

Qingdao Seger Factory,the leading manufacturer of casting and forging parts.

Our main product line includes sand casting,investment casting,die casting,forging and CNC machining.Materials vary from gray iron,ductile iron,stainless steel,steel,aluminum,bronze etc.Our products are widely used for industry of auto

parts,agriculture,machinery,construction etc.

Our main product line includes sand casting,investment casting,die casting,forging and CNC machining.Materials vary from gray iron,ductile iron,stainless steel,steel,aluminum,bronze etc.Our products are widely used for industry of auto

parts,agriculture,machinery,construction etc.

Under ISO9001:2000 quality management system,with professional technical team,our advanced equipment and facilities are well diversified and highly flexible enabling us to offer a wide range of products forms and sizes.Until now,more than 1000 kinds of parts have been exported to Southeast Asia ,North America,Australia,Middle East,European...Products are widely acclaimed.

We are committed to provide best service for all customers with good quality and short lead time.For more details,welcome to contact us.24 hours service for you.

We are committed to provide best service for all customers with good quality and short lead time.For more details,welcome to contact us.24 hours service for you.

Main Technics

Sand Casting

Lost Wax Casting(Investment Casting)

Gravity Casting and Die Casting

Forged

Clients Comment

FAQ

Q1. Are you a factory or trade company?

We are manufacturer and welcome to visit our factory.

Q2. What kind of production service do you provide?

Mould design and macking,casting and forged,machining,surface treatment,assembly,packing.If your parts need stamping,welding etc,we also have cooperated company to help us do related process.

Q3. How about the lead time?

Mold: 3-4 weeks

Mass production: 4-6 weeks

Mass production: 4-6 weeks

Q4. How long should we take for a quotation?

3d drawing:Igs or Step format is ok

If you need machining,send us pdf drawing with machining info

Material number

Quantity

If you have other requirement about packing,surface treatment,tell us together.

With the above info,we could calculate cost for you within 1-2 days.

Q5. What is your payment term?

Mold: 100% prepaid for mould opening and sample preparation

Goods: 40% down payment,balance paid before shipment

Goods: 40% down payment,balance paid before shipment

Q6. What is your MOQ.

Small MOQ is acceptable according to parts' size,design,technics,material.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices