core filling snack food production line puff core filling snack food making machine core filled snack production line

- Category: >>>

- Supplier: Jinan Dayi Extrusion Machinery Co. Ltd.Jinan Ltd.

Share on (1601018011579):

Product Overview

Description

Product Description

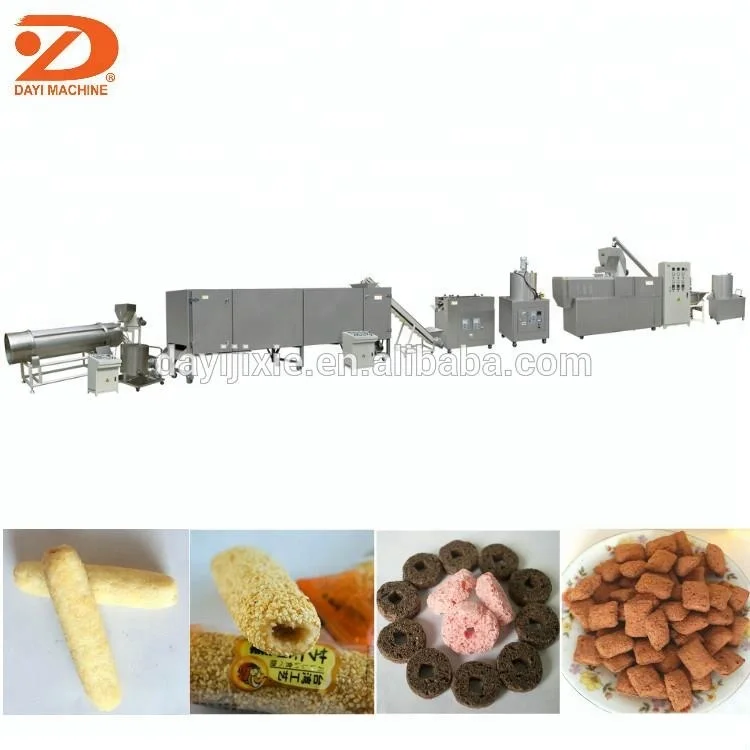

This is fully automatic core filling snacks process line,This line adopt advanced extrusion technology,Include mixing, extrusion, core filling,shaping, drying ,coating and cooling process.with PLC control system which makes easy operation and better performance.For puffed snacks, we can use different ingredients as raw materials, such as rice flour, corn flour, wheat flour, starch and so on. With this line, we can make different shape such as rings, balls, nuggets, core filling tubes and so on. With bigger expansion, the snacks are crispy and tasty.

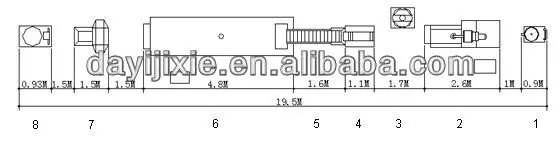

Technical parameters of core filling snacks process line

Model | Installed Power | Power Consumption | Capacity | Dimension |

SLG65-C | 63.41kw | 41kw | 100~150kg/h | 18000*1200*2000mm |

SLG70-A | 86.06kw | 56kw | 250~300kg/h | 23000*2000*3000mm |

SLG85-A | 131.06kw | 98kw | 350~400kg/h | 31000*2000*3000mm |

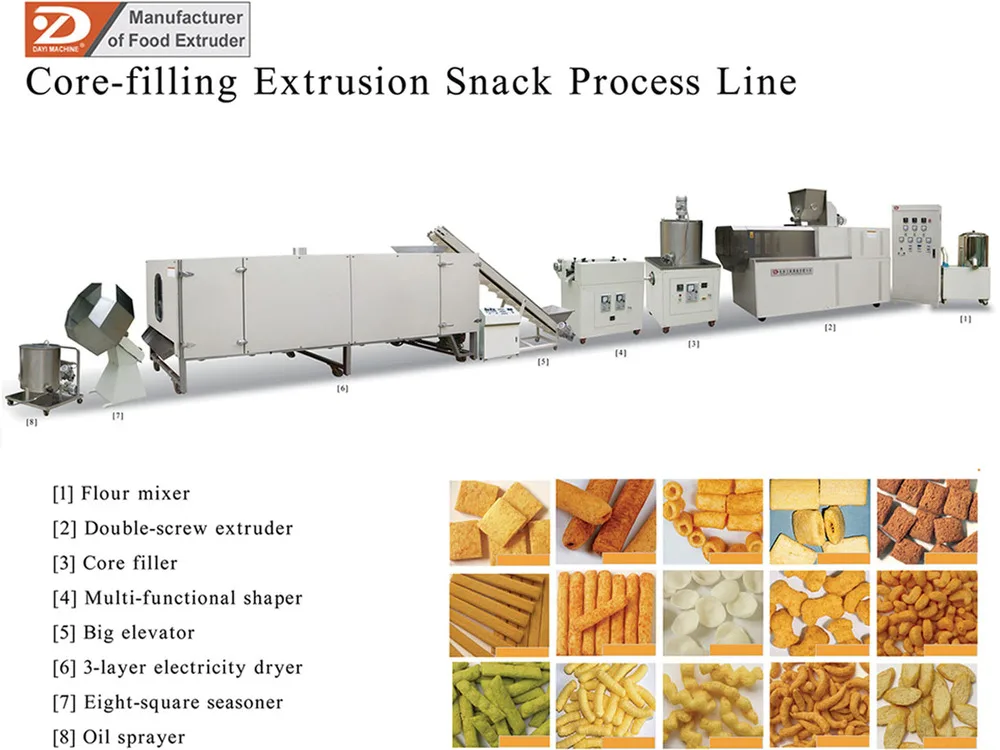

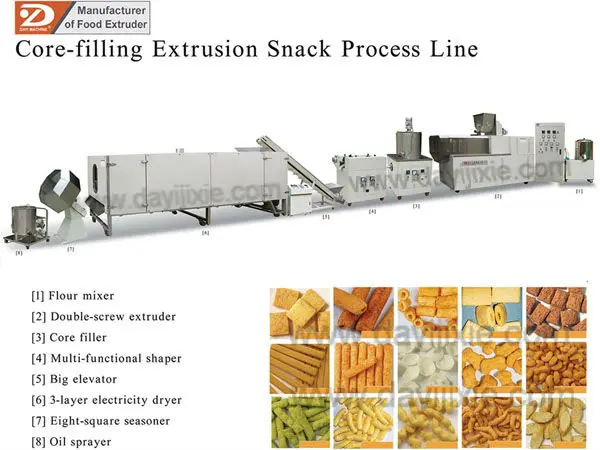

Production Line Plan Diagram

1) Direct transmission betwe en motor and gear box,reducing energy consumption.

2) Feeding,main driving device, and rotary cutting device adopt inverter to adjust the speed with more powerful drive, stable running, and low consumption.

3) Screw is made of alloy steel with long life.Segmental assembled screws are applied tomore kinds of materials and products.

4) Automatic lubrication system can lower down power consumption and prolong the life.

5) Double screws feed equal materials forcibly.

6) Hanging mould and knives seat and bearing knife adjusting system can adjust the kniver exactly and swiftly.

2) Feeding,main driving device, and rotary cutting device adopt inverter to adjust the speed with more powerful drive, stable running, and low consumption.

3) Screw is made of alloy steel with long life.Segmental assembled screws are applied tomore kinds of materials and products.

4) Automatic lubrication system can lower down power consumption and prolong the life.

5) Double screws feed equal materials forcibly.

6) Hanging mould and knives seat and bearing knife adjusting system can adjust the kniver exactly and swiftly.

Details Images

Name | Flour Mixe |

Model | BF-III |

Motor | 5kw |

Capacity | 100kg/batch |

Original: | Jinan,Shandong,China To Mix up the raw material like wheat flour, potato powder,oil. |

Name | Pellet Extruder |

Model | SLG70-A |

Motor | 250~300kg/h |

Capacity | 86.06kw |

Original | Jinan,Shandong,China Cook the raw material and form into different shapes. |

Name | Pattern Machine |

Model | JX-I |

Motor | 0.55kw |

Capacity | With extruder |

Original | Jinan,Shandong,China To make the pattern in the pellet. |

Name | Compound Shape Machine |

Model | QF-III |

Motor | 1.5kw |

Capacity | With extruder |

Original | Jinan,Shandong,China To make the 3d compound shape. |

Name | Multi-layer Diesel/Gas Dryer |

Model | WXH |

Motor | 6kw |

Capacity | 300-400kg/h |

Original | Jinan,Shandong,China To dry out the extra moisture inside of pellet snack. |

Equipment Real Time Shooting

Our Company

About Dayi Machinery

DAYI Extrusion Machinery Co., Ltd. has been established for more than 20 years since 1996 ,with an annual average turnover of more than 100 million.DAYI is a professional food extruder manufacturing company and a national high-tech enterprise integrating R&D, production and manufacturing, product sales and after-sales service.

research and development centre

DAYI has more than 50 senior engineers and technicians and it has trained a production and service team with excellent and high skills.

Inside the plant

DAYI's main business scope includes food extrusion machinery, drying machinery, frying machinery, puffed food machinery .

standardized factory building

DAYI has modern office areas,R&D center and standardized manufacturing workshop,with the building area of more than 20,000㎡.

Certifications

During more than 20 years food machine production, we got much experiences and many certificates, like the CE, ISO 9001, High-tech certification from China government. We will cherish the recognition from all walks of life, and do our best to serve customers around the world.

Packing&Shipping

Package

1.Firstly packed with plastic bags

2.Secondly wooden packing cases

3.Finally putting the wooden cases into the container

4.Ten Days after Full Payment

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Our Advantages

We can keep product design in the same level with internationally advanced technology consistently.We can guarantee customers superior quality machines up to design requirements and perfect working state.

We have high diathesis staff and excellent processing equipment, and quality control runs through the whole production process from parts stock to the beginning of production.

Our technicians can also provide all kinds of relevant technology to make the food production clean, healthy and safe.We provide 1 year complete Guarantee and life-time maintenance service.

Marketing Campaign

FAQ

1.Does your product support international transportation?

Answer: Yes, we support international transportation. Our products can be shipped globally. The transportation method and cost will depend on your order and destination. At checkout, you can choose the shipping option that suits you.

2. Does your product have quality assurance?

Answer: Yes, we have high requirements for the quality of our products and provide quality assurance to support pre factory inspection. You can click here to Contact Us.

3. What’s your Guarantee?

Answer:We provide 1 year complete Guarantee and life-time maintenance service

4. How about the installation?

Answer:We will dispatch our technicians to your factory to guide you installation and commissioning work and training your operator.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices