small cereal breakfast cereal machine corn flakes making machine cornflakes kelloggs breakfast cereals production line

- Category: >>>

- Supplier: Jinan Dayi Extrusion Machinery Co. Ltd.

Share on (1601023355817):

Product Overview

Description

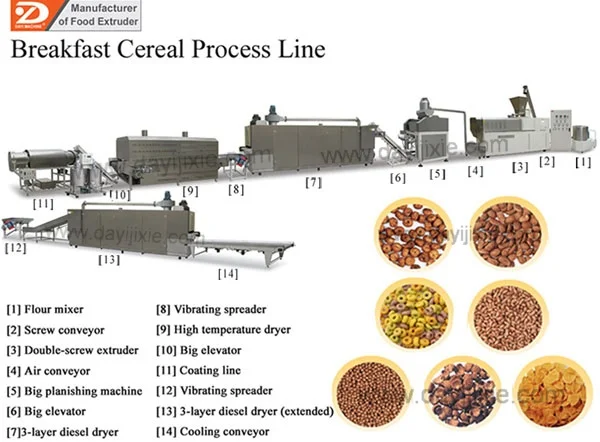

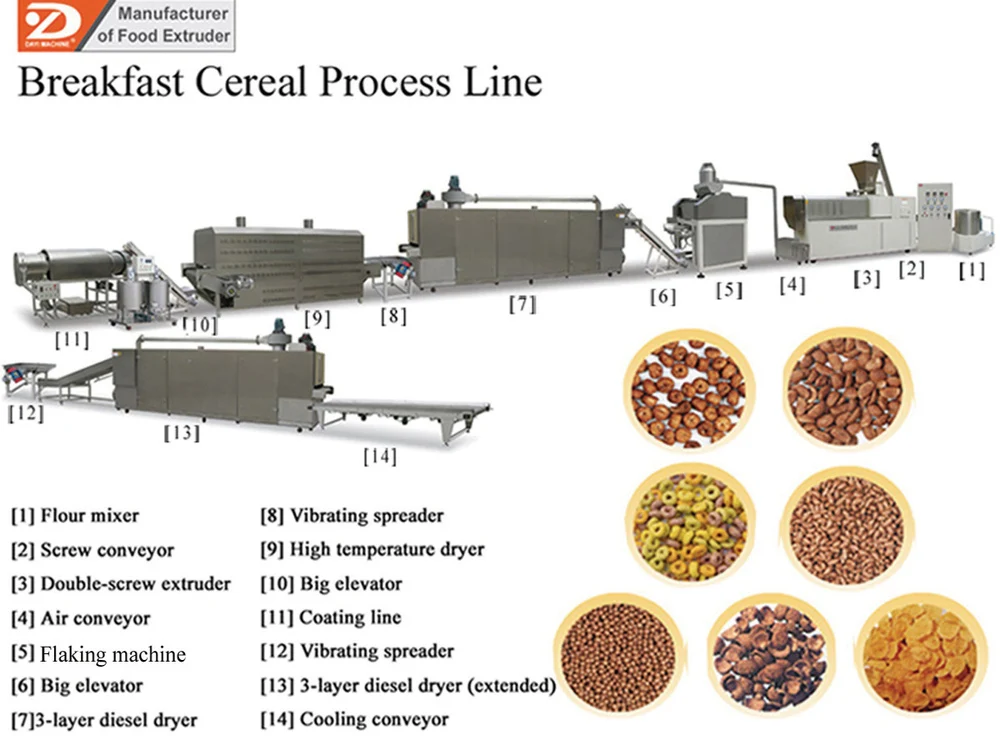

Double Screw Extrusion Machine Corn Flakes Plant

Breakfast cereal food and corn flakes food are crispy food which are produced by breakfast cereal process line using grist as basic material. It is fast and nutritional food with given structure in granule shape, flake shape adn animal shape. Its outstanding characteristic is containing abundant compound carbohydrate and meal fibre. Breakfast cereal can not only strengthen lots of microelement such as vitamin and mineral, but also be added with cocoa powder, sugar powder, honey, and maltose.

You can enjoy it directly by mixing with coffee, milk, yoghourt or functional drink. Children can eat breakfast cereal as sweet crispy snack. There are also natural corn flakes,sweet corn flakes and salty corn flakes according to different flavors.

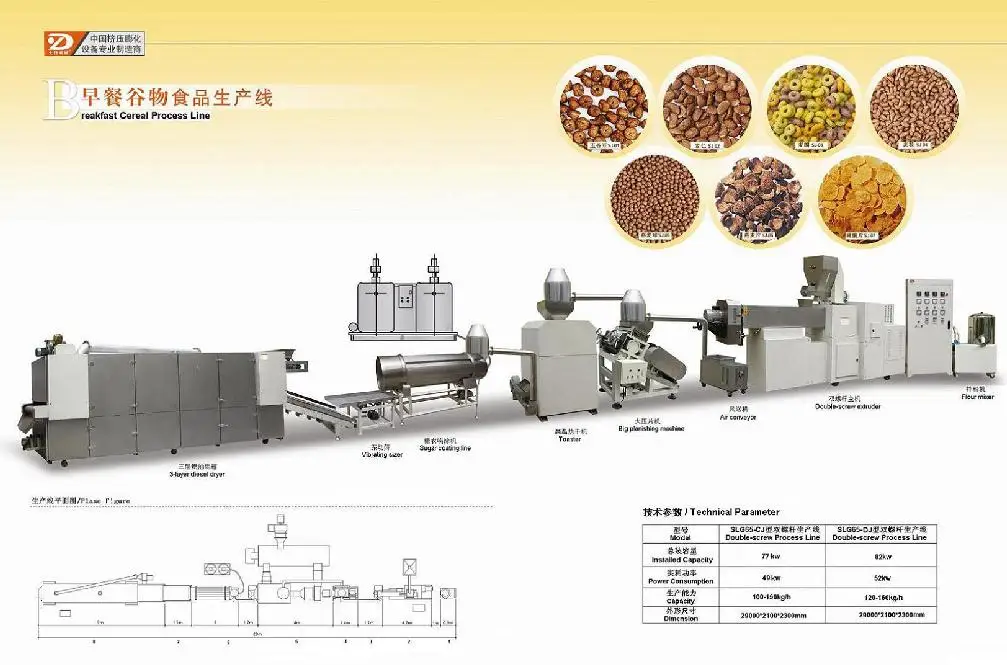

Model | Installed Power | Power Consumption | Power Consumption | Dimension |

SLG65-CJ | 85.97kw | 56kw | 100~160kg/h | 34500*2000*2600mm |

SLG65-DJ | 88.56kw | 57kw | 100~160kg/h | 35500*2000*2600mm |

SLG70-A | 119.06kw | 82kw | 200~250kg/h | 35600*2000*2800mm |

Main Features

1) Direct transmission betwe en motor and gear box,reducing energy consumption.

2) Feeding,main driving device, and rotary cutting device adopt inverter to adjust the speed with more powerful drive, stable running, and low consumption.

3) Screw is made of alloy steel with long life.Segmental assembled screws are applied tomore kinds of materials and products

4) Automatic lubrication system can lower down power consumption and prolong the life.

5) Double screws feed equal materials forcibly.

6) Hanging mould and knives seat and bearing knife adjusting system can adjust the kniver exactly and swiftly.

Transmitting drive power: 0.37kw

Speed of press roller: 0~85rpm

Dimension: 1800×1700×1650mm

Driving power: 5.5KW

Heating power: 54KW

Width of mesh belt: 1200mm

Dimension: 12670 × two thousand × 2890mm

ensure uniform arrangement of materials.

2. Train the first-line operator.

3. Operation/ Service/ Maintenance Manual: Provided In English.

4. 1-2 engineers will be arranged for customer

We Recommend

New Arrivals

New products from manufacturers at wholesale prices