Arrow CN panko bread crumbs making machines breadcrumbs production line

- Category: >>>

- Supplier: Jinan Arrow Machinery Co. Ltd.Jinan Ltd.

Share on (1601035562906):

Product Overview

Description

Product Description

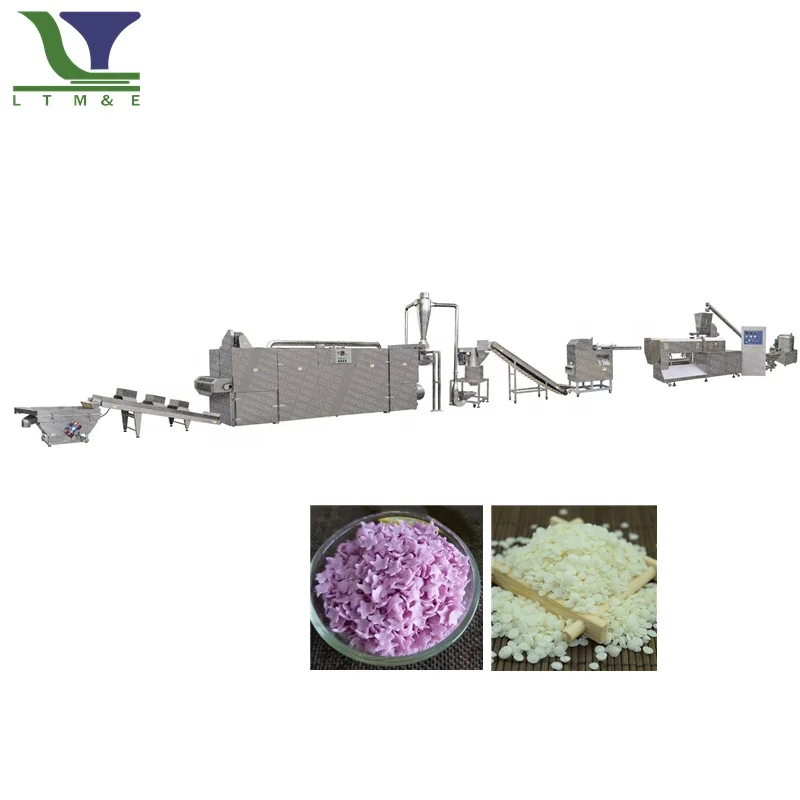

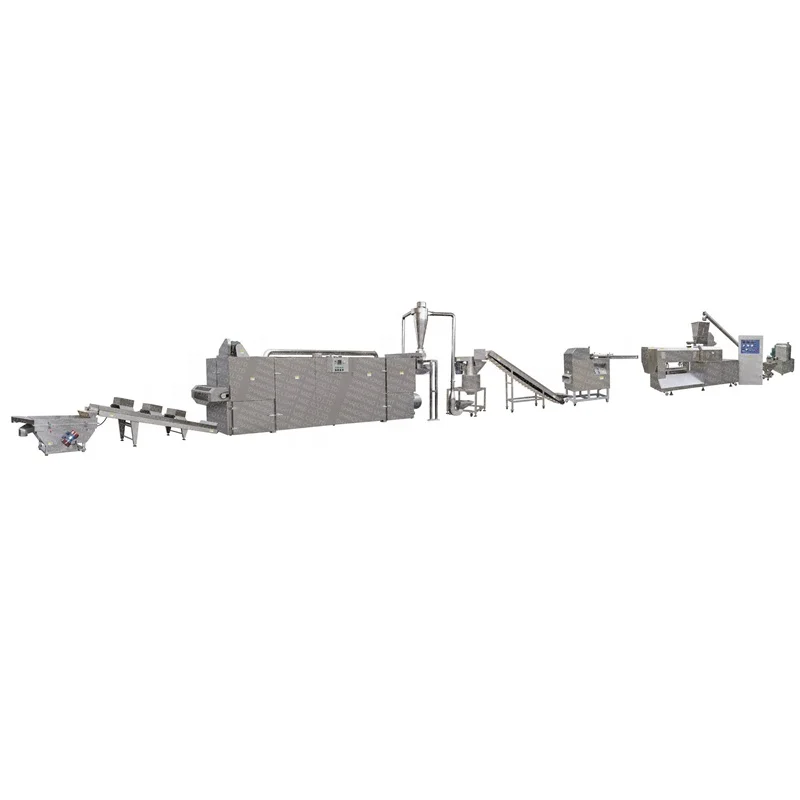

Our lines are designed based on advanced extrusion technology, and their quality and operation are up to domestic advanced level. The machines in the production line include Flour Mixer, Screw Conveyer, Double-screw Extruder, Vibrate Cooler, Crumbs Sucking Conveyor, Vibrate Sifter, Crumbs Sucking Conveyor and Vibrate Sifter. From mixing materials, extruding, cutting, drying to finished products are done in one automatic line.

Application Display

Extruded breadcrumbs are made by directly extruding and pulverizing flour or other ingredients and producing small crumbs or flakes similar to traditional breadcrumbs.

They are characterized by a hard and brittle texture, a chewy mouthfeel, and an uneven appearance.

Panko breadcrumbs are fermented bread crumbs, they have a distinct bread-like flavor, a good taste after frying, good color, and low oil absorption.

They are characterized by a hard and brittle texture, a chewy mouthfeel, and an uneven appearance.

Panko breadcrumbs are fermented bread crumbs, they have a distinct bread-like flavor, a good taste after frying, good color, and low oil absorption.

Machine Details

By using the batch frying machine, eight square flavoring machine can reach the auto-processing bugles and crispy chips. This not only saves cost, but also has the characteristics of energy saving and fast heating.

Our Twin-Screw Extruder features a special barrel and modular screw design, adhering to European standards. Controlled by a PLC system, it ensures easy production.

The Automatic Continuous Fryer integrates fresh oil through an oil circulation system, along with real-time cleaning and adjustable frying times and temperatures to suit different products.

Company Profile

Jinan Arrow Machinery Co., Ltd is a company specializing in R&D, production, sales, application promotion of food engineering projects. As a professional food processing equipment &whole plant engineering problem solver in China, machines served for more than 1200 companies, export to 118 countries, more than 30 years engineering team.

We aim to create a great future together with global customers. The quality of the equipment has been checked at various levels, and it has certificates such as CE, ISO9001, 18 practical patented technologies, and 6 software copyrights. Adhering to the concept of "Excellent quality, Prominent Service, Faithful Attitude, Promise Fulfilled "Our team from Pre-sale service and after-sale service will prove that your choice is worth it.

FAQ

1.What is the capacity of the production line?

A: The production line can be customized to meet different capacity requirements, with a range of options available to suit varying production needs (From 150kg to 1500kg per hour).

2.Are the machines easy to operate?

A: Yes, the machines are designed with user-friendliness in mind and are easy to operate with minimal training. The control systems are also intuitive and straightforward.

3.What kind of maintenance is required for the machines?

A: Regular maintenance is recommended to ensure optimal performance and extend the lifespan of the machines. Routine tasks such as cleaning, lubrication, and inspections are typically required.

4.Can the machines be used to produce other food products besides bread crumbs?

A: Yes, the machines can be used to produce a range of food products by adjusting the parameters and changing the ingredients used. This makes the production line versatile and adaptable to changing market demands.

5.What kind of after-sales support is available for the machines?

A: We provide comprehensive after-sales support, including training, technical assistance, and maintenance services to ensure that the machines operate at peak performance and to minimize downtime.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices