AAC/ ALC Panel Wall autoclaved aerated concrete panel /floor panel

- Category: >>>

- Supplier: Shandong Sinomega Innovation Material Co. Ltd.

Share on (1601036485003):

Product Overview

Description

Heat Insulation Environmental AAC ALC Floor Slab

INTRODUCTION

INTRODUCTION

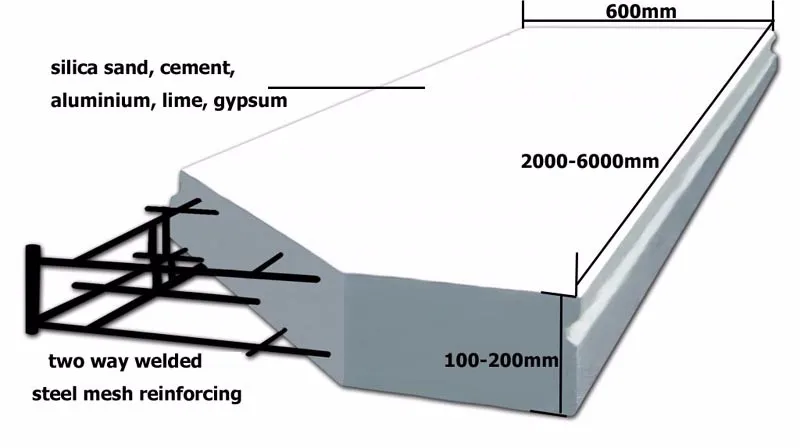

AAC (shorted for autoclaved aerated concrete) Panels are mainly made of silica sand, cement, aluminium, lime, gypsum, processing in the condition of high temperature, high pressure and steam curing. They could be used in industry buildings and residential buildings. Now, they are welcomed by more and more customers.

SPECIFICATIONS

Technical Information:

| Item | Model | ||

| B05 | B06 | ||

| Anti-pressure Strength | A3.5 | A5.0 | |

| Dry Density Grade(kg/m3) | <=525 | <=625 | |

| Thermal conductivity[W/(m.k)] | <=0.14 | <=0.16 | |

| Anti-freeze 15 times Freeze &Melt | Quality loss(%) | <=5 | |

| Strength after freezing(Mpa) | >=3.2 | ||

| Dry Shrink Coefficient | <=0.5 | ||

Specifications of AAC panels for walls:

Thickness(mm) | 50 | 75 | 100 | 120 | 150 | 175 | 200 |

Maximal Length (mm) | 2000 | 3000 | 4000 | 4500 | 6000 | 6000 | 6000 |

Specifications of AAC panels for roofing:

Thickness/mm | 75 | 100 | 125 | 150 | 175 | 200 |

Intensity of Pressure(N/m2) | Maximal Length (mm) | |||||

800 | 2000 | 3000 | 3500 | 4200 | 4800 | 5200 |

1000 | 2000 | 3000 | 3500 | 4200 | 4800 | 5200 |

1200 | 1960 | 2920 | 3400 | 4080 | 4640 | 5200 |

1400 | 1920 | 2840 | 3300 | 3960 | 4480 | 5200 |

1600 | 1880 | 2760 | 3200 | 3840 | 4320 | 4950 |

1800 | 1840 | 2680 | 3100 | 3720 | 4160 | 4900 |

2000 | 1800 | 2600 | 3000 | 3600 | 4000 | 4800 |

2200 | ------ | 2500 | 2850 | 3350 | 3750 | 4700 |

Specifications of AAC panels for floors:

| Length(mm) | 100 | 125 | 150 | 175 | 200 |

| Intensity of Pressure(N/m2) | Maximal Length (mm) | ||||

| 2400 | 2400 | 2700 | 3100 | 3500 | 4000 |

| 2600 | 2330 | 2630 | 3030 | 3430 | 3950 |

| 2800 | 2260 | 2560 | 2960 | 3360 | 3900 |

| 3000 | 2200 | 2500 | 2900 | 3300 | 3850 |

| 3200 | 2130 | 2460 | 2830 | 3230 | 3780 |

| 3400 | 2060 | 2430 | 2760 | 3160 | 3730 |

| 3600 | 2000 | 2400 | 2700 | 3100 | 3670 |

| 3800 | 1950 | 2350 | 2650 | 3050 | 3620 |

| 4000 | 1900 | 2300 | 2600 | 3000 | 3530 |

| 4200 | 1840 | 2240 | 2560 | 2960 | 3480 |

| 4400 | 1780 | 2180 | 2520 | 2920 | 3430 |

| 4600 | 1720 | 2120 | 2480 | 2880 | 3400 |

| 4800 | 1660 | 2060 | 2440 | 2840 | 3360 |

| 5000 | 1600 | 2000 | 2400 | 2800 | 3340 |

| Item | Model | Test result (db) | Standard of test | Application |

| 1 | 100mm AAC panel | 36.7 | GBJ75-84 GBJ121-88 | interior walls of housing units/general division walls of schools/hotels/office buildings |

| 100mm AAC panel+2 sides of putty (3mm) | 40.8 | |||

| 2 | 120mm AAC panel | 41.7 | interior walls of housing units/general division walls of schools/hotels/office buildings(5A Grade) | |

| 120mm AAC panel+2 sides of putty (3mm) | 45.1 | |||

| 3 | 150mm AAC panel | 43.8 | interior walls of housing units/schools/hotels/office buildings | |

| 150mm AAC panel+2 sides of putty (3mm) | 45.6 | |||

| 4 | 180mm AAC panel | 46.7 | division walls of rooms that require silence | |

| 180mm AAC panel+2 sides of putty (3mm) | 48.1 | |||

| 5 | 200mm AAC panel | 49.8 | division walls of rooms that require silence, eg., a cinema, a 5-star hotel | |

| 200mm AAC panel+2 sides of putty (3mm) | 51.3 | |||

| 6 | (75+5space+75)mm AAC panels | 48.6 | division walls of rooms that require silence in some industry, eg., division walls of a high-standard Hotel | |

| (75+5mineral wool+75)mm AAC panels | 54.8 | |||

| (75+5mineral wool+75)mm AAC panels+2 sides of putty (3mm) | 57.6 |

Shandong Yuanda Innovative Materials Co., Ltd is professional in innovative construction materials of walls. Our company has introduced German production techniques and realized industrialization of construction industry for insulated external walls, AAC panels fabricated walls, etc. We have 8-year professional experience of development and application in the construction field, such as wall materials, steel-structure buildings. We can supply all-around service from fabrication designing to building operations.

The main products are: ALC/AAC (Autoclaved Lightweight/Aerated Concrete) panels, AAC blocks with function of thermal insulation, AAC accurate blocks. Mortar are produced by German m-tec Machinery & production techniques. The factory occupies 180,000 square meters and has 2 production lines. The annual production amounts are: 400,000 cubic meters of panels and 600,000 cubic meters of AAC blocks. Our products sell well not only in China, but also in Australia, New Zealand, Korea, Southeast Asia, Africa, middle east, etc.

If you needed wall materials and request for fabrication of the materials, please feel free to contact us! We will provide the best service! We sincerely welcome customers to visit our factory!

If buyers have requirements for packaging, we would do as requested. Otherwise, goods would be shipped by wooden pallets, and corner protectors on all sides.

1. What is AAC Floor Slab?

Autoclaved Aerated Concrete (AAC) is a lightweight concrete that is formed into blocks and panels for a wide range of loadbearing and non-loadbearing construction applications. It is manufactured from silica sand, cement, recycled material, lime, gypsum, aluminium paste and aerating agents. It is moulded, cut and steam pressure cured in an autoclave before being packed, ready for transport.

2. Is AAC Floor Slab a new building material?

Aerated Concrete Autoclaved (AAC) is an amazingly innovative building material that has been used in Europe for more than 80 years and in the US for more than 15 years.

3.Where has AAC Floor Slab been used?

It can be used ranging from low rise industrial/commercial developments to high rise offices or medium density residential buildings.

4. Is AAC Floor Slab a load bearing material?

The intensity of pressure for cube is more than 4mpa. The load bearing capacity for one point is more than 1200N. The rebars within AAC panels are made according to computer calculating force. As a non-loadbearing cladding, AAC panels can be used under circumstances of pressure.

6.What are the benefits of AAC Floor Slab over other building materials?

a.Cost effective - lightweight panels allow for reduced structural components and smaller lifting equipment.

b. Excellent thermal resistance performance.

c. Acoustic performance - effective sound transmission barrier between external and internal environments of the building.

d. Excellent fire rating properties.

e. No wet trades - less mess and a cleaner, safer work area.

f. Less wastage - significantly reduced waste as panels can be custom-made to length requirements.

g. Fewer waste bins and less crane movements.

h. Design flexibility - panels can be easily cut and routed to suit design requirements.

i. Panel lengths up to 6 metres.

j. Strong, secure and durable with corrosion protected steel-reinforced panels.

Buying Procedures:

1. Enquiry: Please contact us by emails, phone and let us know your inquiry.

2. Discussion: Specify the items you desire, confirm specification.

3. Delivery Item: FOB QINGDAO ( If you want to deal with EXW/CIF/CNF term instead of FOB, please specify)

4. Payment: 30% T/T in advance, balance 70% before shipment, western union, escrow.

5. Production Lead Time: 7~10 days for 20' container, 15~20 days for 40' container.

Contact Us:

Shandong Yuanda Innovative Materials Co., Ltd

Address: No. 20 Zhuzhou Road, Laoshan District, Qingdao, Shandong Province, China

Tel: +86 159 7214 1762(Whatsapp)

+86-532-8099 6919

Website: shandongyuanda.en.alibaba.com

Email: nancy<@>yuandachn.com

We Recommend

New Arrivals

New products from manufacturers at wholesale prices