Best Choice Synthetic Ammonia Plant 3000t/a Compact Equipment Small Ammonia Plant for Coal Industry

- Category: >>>

- Supplier: WOBO Industrial Group Corp.WOBO Corp.

Share on (1601036491844):

Product Overview

Description

Green Ammonia Plant

Best Choice Synthetic Ammonia Plant 3000t/a Compact Equipment Small Ammonia Plant for Coal Industry

Product Description

Product Parameters

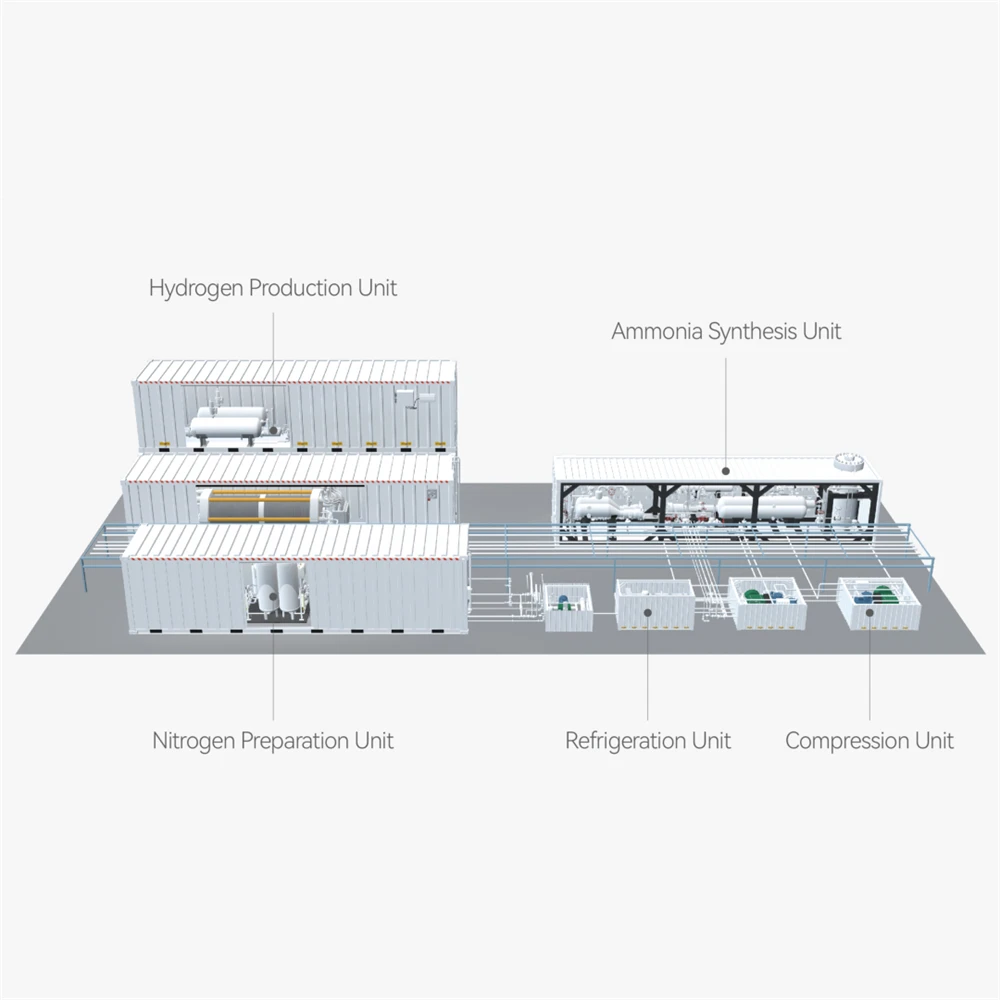

WGA-2000 LAYOUTDIMENSIONS AND MAIN PARAMETERS | ||||||||||||

Unit | Length(M) | Width(M) | Height(M) | Cooling Water(T/h) | Electricity Consumption (kWh/h) | Floor Area (m2) | ||||||

Hydrogen Preparation Unit | 13 | 6 | 5.5 | 80 | 2500 | 78 | ||||||

Nitrogen Preparation Unit | 10 | 6 | 2.9 | 10 | 60 | 60 | ||||||

Compression Unit | 10 | 5 | 1.7 | 5 | 55 | 50 | ||||||

Ammonia Synthesis Unit | 12 | 2.5 | 2.8 | 6 | 37.5 | 30 | ||||||

Refrigeration Unit | 6 | 2.5 | 2.5 | 20 | 85 | 15 | ||||||

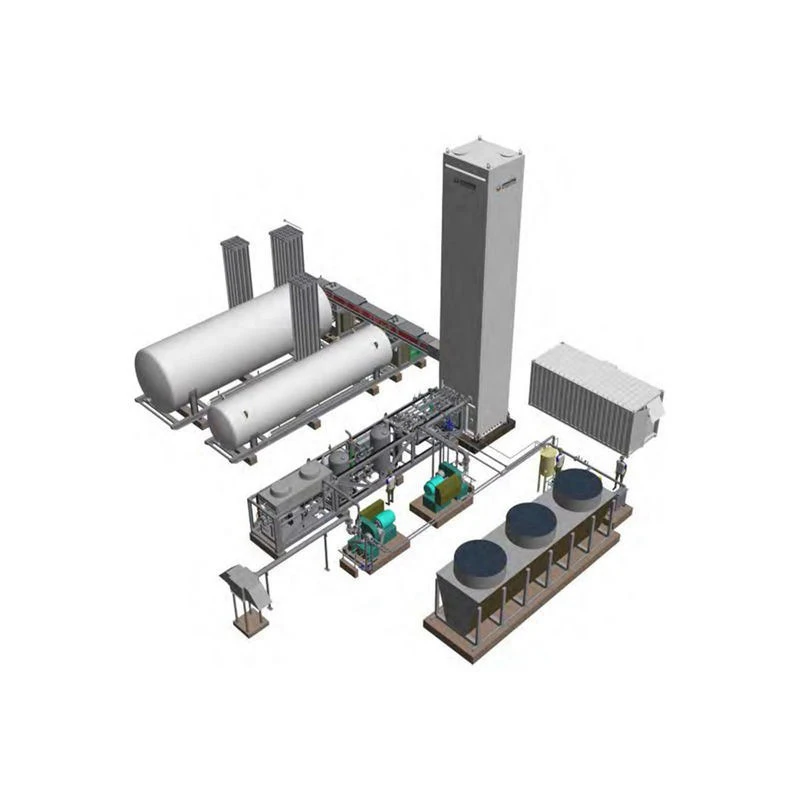

WGA-20000 LAYOUTDIMENSIONS AND MAIN PARAMETERS | ||||||||||||

Unit | Length(M) | Width(M) | Height(M) | Cooling Water(T/h) | Electricity Consumption (kWh/h) | Floor Area (m2) | ||||||

Hydrogen Preparation Unit | 60 | 28 | 10 | 800 | 25000 | 1680 | ||||||

Nitrogen Preparation Unit | 15 | 7 | 4 | 100 | 600 | 105 | ||||||

Compression Unit | 14 | 10 | 2.5 | 50 | 550 | 140 | ||||||

Ammonia Synthesis Unit | 12 | 7 | 4.5 | 60 | 132 | 84 | ||||||

Refrigeration Unit | 10 | 3.5 | 3 | 200 | 650 | 35 | ||||||

Technical Principle

1. Renewable Energy Generation: The device harnesses renewable energy sources such as solar power or wind power to generate electricity. These clean energy sources are sustainable and have minimal or no carbon emissions.

2. Electricity Conversion: The generated electricity is then utilized to power the electrolysis process. Electrolysis involves passing an electric current through water (H2O) to break it down into its constituent elements, hydrogen (H2) and oxygen (O2). This process occurs in an electrolyzer unit, which typically consists of two electrodes immersed in water.

3. Hydrogen Production: The electric current causes the water molecules to split, with hydrogen ions (H+) being attracted to the cathode (negative electrode) and oxygen ions (O2-) being attracted to the anode (positive electrode). The hydrogen ions combine to form hydrogen gas (H2) at the cathode, which is collected as a product.

Green ammonia production and uses

4. Air Separation: A portion of the generated electricity is directed to an air separation unit. This unit utilizes techniques such as cryogenic distillation or membrane separation to separate the air into its main components, primarily nitrogen (N2) and oxygen (O2). The nitrogen gas is used in the subsequent step for the synthesis of ammonia.

5. Ammonia Synthesis: The separated hydrogen gas from step 3 and the nitrogen gas from step 4 are combined in a reactor. Through a chemical synthesis process known as the Haber-Bosch process, the hydrogen and nitrogen react under specific temperature and pressure conditions, facilitated by catalysts, to produce ammonia gas (NH3). This ammonia gas can be collected and stored for various applications.

Project Case

Related products

Ammonia decomposition catalyst

Ammonia synthesis plant

Hydrogen production equipment

Nitrogen production equipment

Company Profile

We Recommend

Cryogenic air Separation Unit Gas with Two Columns Oxygen Nitrogen Producing Manufacturers

$170,000.00-180,000.00

New Arrivals

New products from manufacturers at wholesale prices