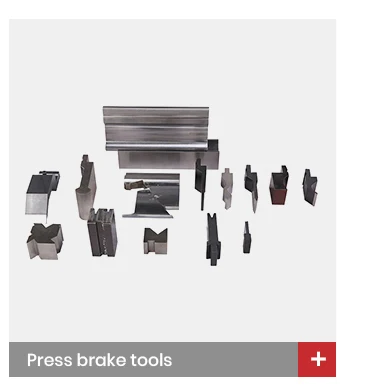

mult V press brake Punch And die press brake tooling

- Category: >>>

- Supplier: Maanshan Shenlite Heavy Industry Machinery Co. Ltd.

Share on (1601041389350):

Product Overview

Description

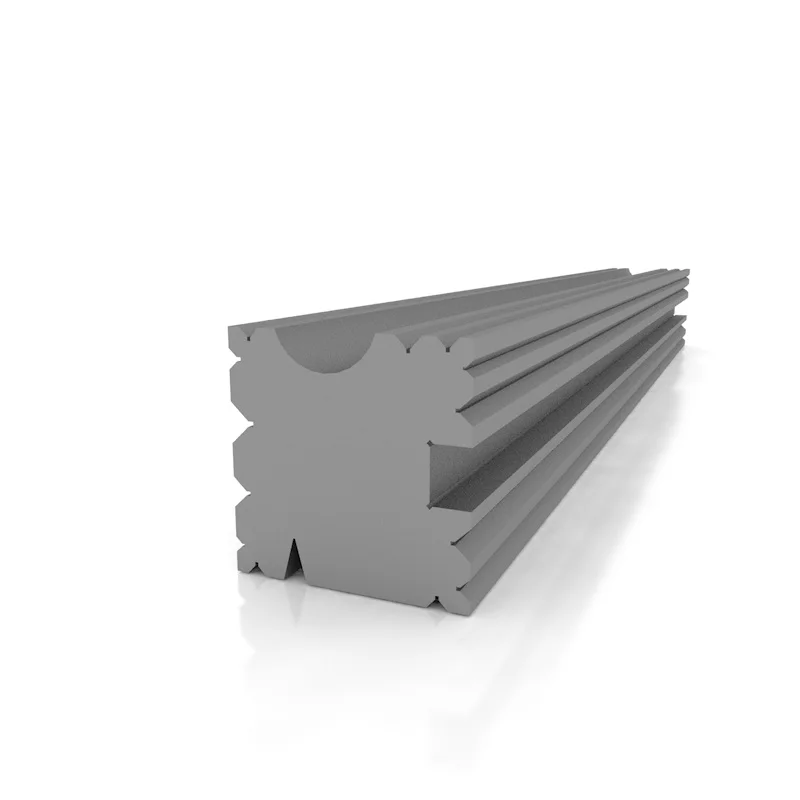

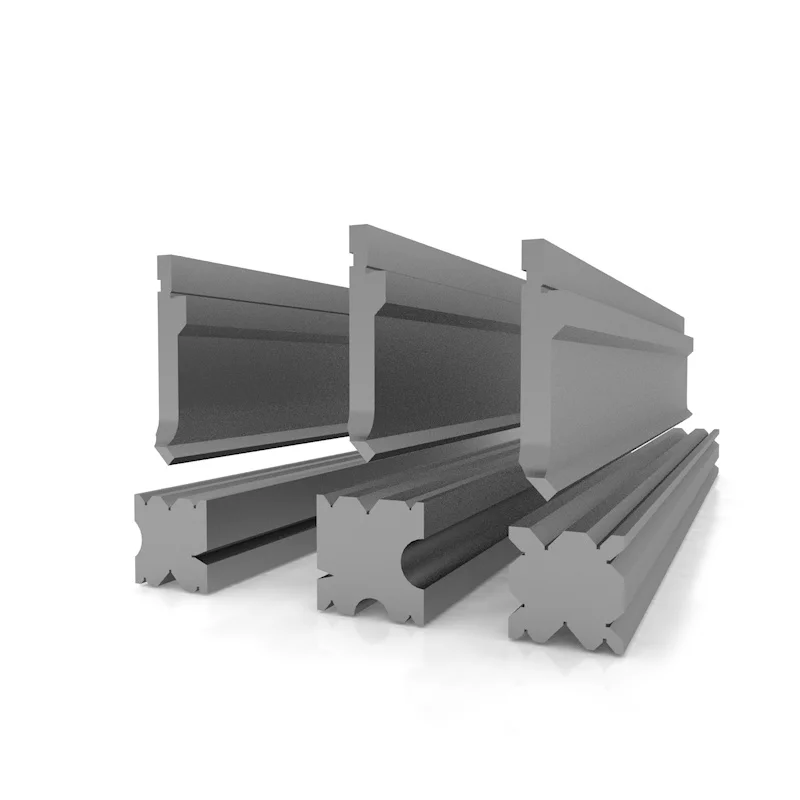

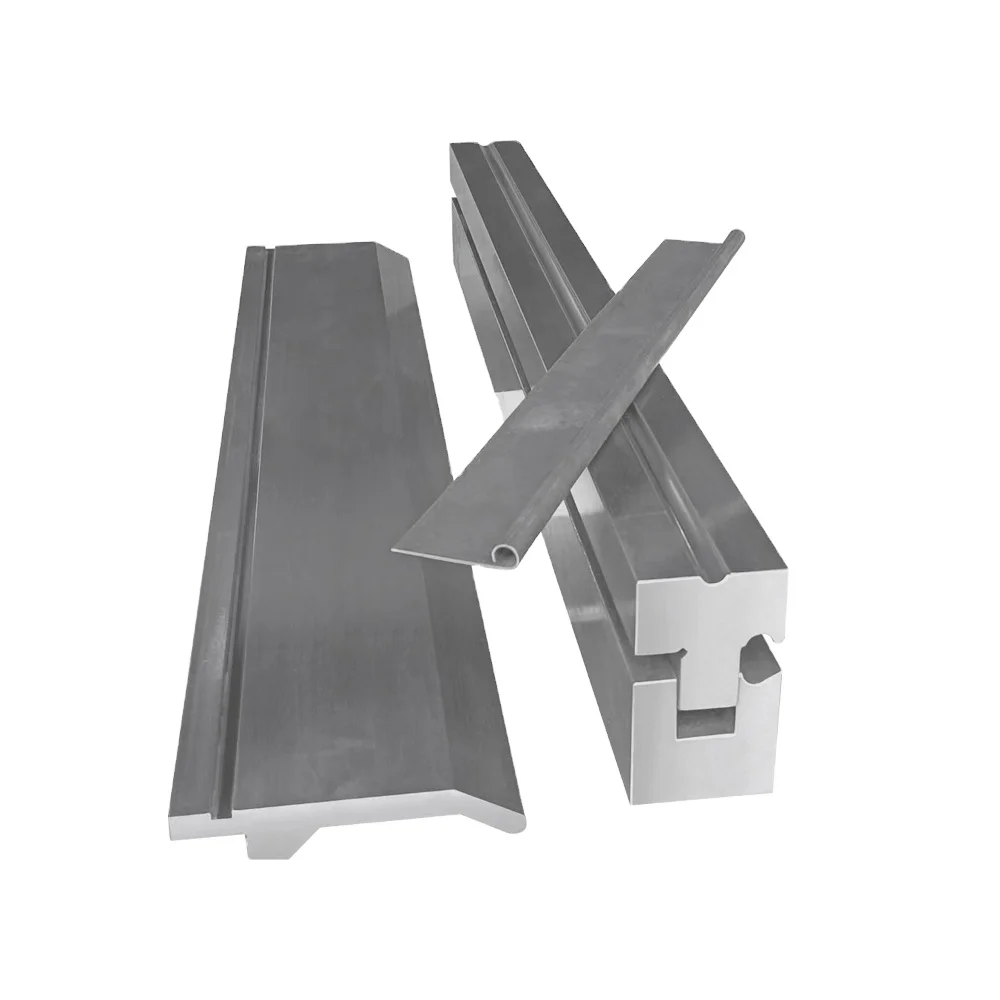

Press brake tooling and Dies. It is a tool used by the bending machine to form and process sheet metal.

This tool consists of various parts, and different molds consist of different parts.

It mainly realizes the processing of the shape of the article by changing the physical state of the formed material.

A tool used to make a blank into a specific shape and size under the pressure of a bending machine.

| Product Name | Press Brake Accessories Mould |

| material | 42CrMo |

| MOQ | 1 PCS |

| Packing | Wooden Box |

| Size | Customized |

| Advantage | Perfect High Cutting Efficiency |

| Hardness | 45-50HRC |

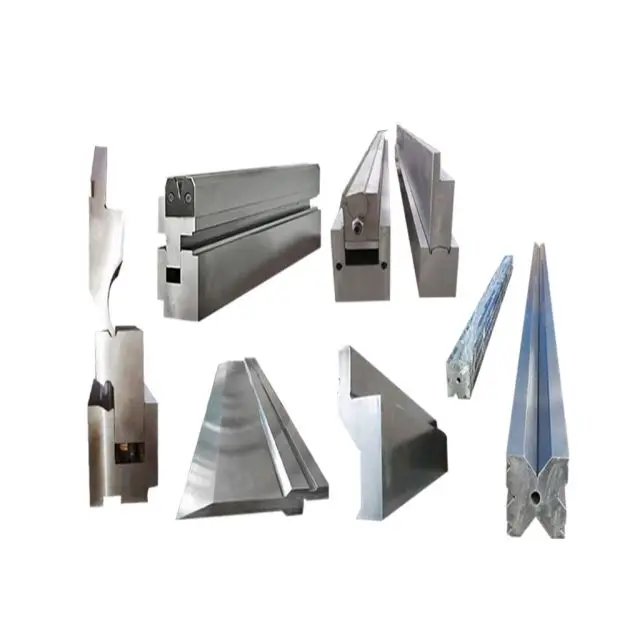

| Standard | AMADA, European, Segmented, Arc, International Standard, Three Point, Non-Streaking, Adjustable Groove, Special, etc |

| Certification | ISO9001 |

Support customization, please let us know your requirements

1. Material

2. Forging

3. a. Miller Processing (if your products are small)

b. Planer Processing (if your products are large)

4. Precisional Grinder Processing

5. Finished Products

6. Measuring

7. Packing: Wooden crate with soft film layers inside

8. Delivery Details: Shipped in 10--20 days after payment

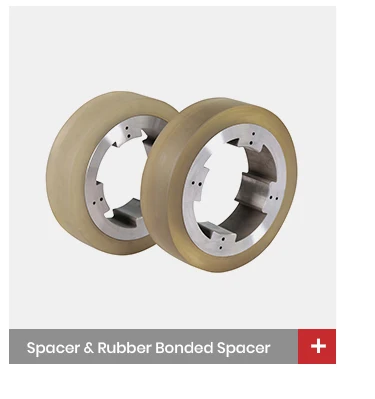

We can supply various kinds of press brake tooling clamps. The mainly two types is normal type and fast type.

We also can supply hydraulic clamps. In addition to the rapid clamping of the bending machine mold,

it has the function of preventing the clamping of the mold and adjusting the uniform force of the mould.

| fit for any press brake,practical and easy to set and replace |

| High-strength alloy quenched and tempered steel with high strength and good toughness |  |

| Through hardening produces the grain structure for durability and consistent cutting characteristics |

| Made by master machinists, supported by leading edge materials, science, and research |

|

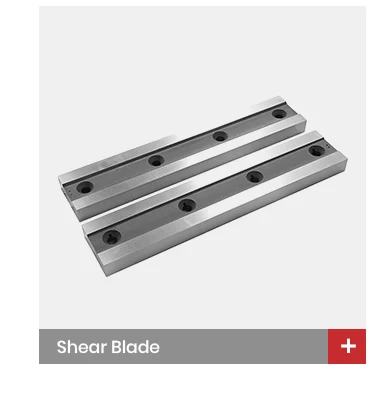

Shinite MACHINERY Co., Ltd. is mainly engaged in the design, R & D, manufacturing, sales and service of shear blades (shear blades) such as medium and heavy plate,hot continuous rolling, cold rolling, rod and wire, profile and so on in the metallurgical industry.Founded in 2013, the company covers a total area of 43000 square meters and has 28000 square meters of standardized modern plant buildings such as smelting, forging, blanking, rough processing, heat treatment, finishing, R & D center and office building.

1. Can you put my brand name (logo) on these products?

Yes we can

2. When can you ship the products after we make payment?

Production time is normally 10-25 days. We will deliver your products to port in 2 days

3. What is the Minimum Order Quantity (MOQ) for your OEM service?

MOQ:1pcs

4. How can you guarantee the quality?

We are the only constitutor of Chinese National Press Brake Mold Industry Standard. We will offer you 3 months guarantee once you purchase from us. We have IQNET Certificate.

5. Is it possible to visit your company? How can I get there?

We would love to have you. We can send you invitation for VISA application and we will collect you in Nanjing Airport or Railway station.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices